Photos are for informational purposes only. View product specification

please use latin characters

SHOCK AND VIBRATION ABSORBING ALUMINUM TRANSIT CASE

The MILEX case is a water and dust proofed, shock and vibration absorbing aluminum transit case for 19 inch electronics. MILEX transit cases are NATO approved and designed to meet the rigid requirements of U.S. MIL specifications and other MIL standards worldwide. Together with a large range of accessories such as cooling systems, racks, drawers and slides, MILEX aluminum transit cases represent the most comprehensive line available today for the safe packaging of mobile electronics. MILEX transit cases are made exactly to customer’s specifications. DESAPRO has developed a unique expertise in designing and custom manufacturing to deliver the right quality for your application on time.

MILEX aluminum transit cases are designed to meet the rigid requirements of MIL-STD-810G and other appropriate military standards for a product of this kind. MILEX cases are designed and manufactured to the specific requirements of environmental protection required by the equipment being contained and transported which provides the maximum protection while also affording other essential and desirable features.

The size of the MILEX case is determined by the size the equipment demands. However, due to the positioning of the DESAPRO shock mounts the space between the inner chassis and outer shell is minimized with equal or better shock and vibration properties. This feature means that the overall dimension of MILEX cases is as small as it can be without sacrificing protective characteristics.

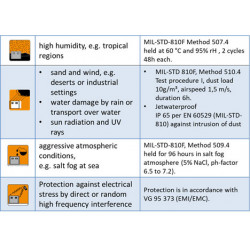

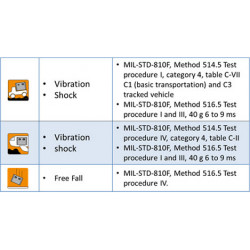

PROTECTION AGAINST ENVIRONMENTAL STRESS:

Undesirable influences from various sources which occur during transport, storage, or operations can have a damaging effect on sensitive goods and therefore present a considerable risk. These risks are mitigated by using DESAPRO cases. DESAPRO cases protect against many environment stress’s:

Protection against climatic stress such as

Protection against internally product stress

Protection against electronic stress such as electromagnetic interference (EMI), RFI

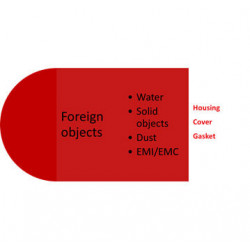

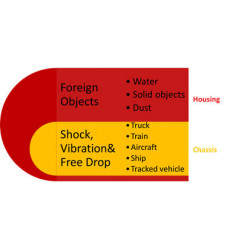

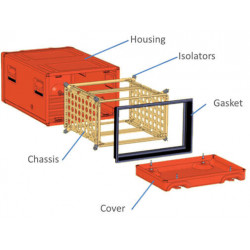

THE MILEX ALUMINUM TRANSIT CASES CONSIST ESSENTIALLY OF THREE MAIN PARTS:

Self-supporting housing

A welded and rigid construction forms a self-supporting shell that is both light and rugged. The entire aluminum construction is shock proof and resistant to extreme temperature change, conductive and fully recyclable. Stacking feet on the bottom and indentations on the top of the housing provide stable stacking of the cases. The standard equipped cases include a pressure equalization valve. Case connections and securing the cases to any bolting pattern are available for specific applications.

Shock mounted chassis

The core of the case is a shock mounted chassis. Depending on the model and size, equipment can be fitted either from the front or the rear of the case. In order to keep the weight down and allow for optimal ventilation, the chassis are designed with large holes. The chassis is connected to the housing shell by an electrical ground strap.

Cover

All MILEX cases are protected against outside influences through a bolted cover with gasket. Easily operated closures are recessed in the housing cover and ensure a solid seal. The cover space can be used for I/O panel, windows, cable pouches, ventilation louvres etc.

TYPES

THERE ARE FOUR TYPES OF MILEX 19 INCH RACK MOUNT TRANSIT CASES

SHOCK MOUNTED

The MILEX 19’’ Transit Cases are intended for use in extreme conditions. The electronics are attached to a shock mounted chassis, not directly to the shell. A minimum of 8 shock and vibration absorbers serve to deflect any mechanical stress on the housing. After attachment of the chassis, the case is securely sealed with a cover to protect the contents against dust, sand and water.

HARD MOUNTED

The MILEX Hard mounted transit case is a standard 19 inch Case without a shock mounted chassis. It is intended for applications where vibration protection is not critical. All other protective features and outer dimensions are equivalent to the Shock mounted case.

WIRE ROPE

The MILEX Wire rope transit case is a 19 inch transit case with the chassis mounted on stainless steel spiral wire rope shock absorbers. These types of shock absorbers are used where electronics have to be protected from vibration and particularly severe shock. The wire rope shock absorbers ensure the necessary deflection, not provided by the shock absorbers in the shock mounted transit cases. Typical applications are shock protections on ship, submarines, helicopters or other aircrafts.

MILEX PRO

MILEXPRO is the newest generation of robust transit cases for the transport of sensitive electronics, IT, and measuring systems. It combines the high value by shortening the integration time of your hardware and easy access during transport and/or in operations. The closing system is unique and supported by a revolving frame system, which is guided in the X- & Y- axis thus centralizing the cover automatically. The long lasting original features of the MILEX are kept in place enabling the stacking compatibility is possible with other MILEX cases.

THE MAIN ADVANTAGES OF THE MILEXPRO ARE

FLEXIBILITY THROUGH A VARIETY OF MILEX OPTIONS

WE OFFER CUSTOM ALUMINUM TRANSIT CASE OPTIONS TO MEET YOUR SPECIFIC NEEDS

A large selection of standard accessories are available

EMI AND RFI SHIELDING OPTIONS

EMI Gasket

Electronically conductive gasket installed in the housing to provide electrical contact between the covers and the housing. This gasket also provides weather protection to the case when the covers are mounted.

EMI Frame

A special EMI thight fame manufactured with alodine aluminum can be used for additional EMI protection. This gives the maximum protection to the electronics in the case. In order to dissipate heat produced by the electronics, the walls of the frame have 3mm (0,12’’) holes, average distance between holes is 4mm (0,14’’).

EMI conductive skirt seal

To eliminate the risk of water or dust contamination to the interior of the case when the covers are removed, a flexible seal between the chassis and housing can be specified and fitted. This flexible skirt seal does not affect the anti vibration characteristics of the case. Sealing of the space between the housing and the frame results in IP 65 protection. The skirt seal is electrically conductive.

MILEX DESIGN CHARACTERISTICS AND FEATURES

Variety of Standard Sizes (DIN41494 / IEC297)

MILEX case performance is dependent on a wide-variety of variables such as payload weight, payload center-of-gravity, payload fragility, payload mounting, payload fastening, test durations, test sequencing, customer pass/fail criteria and many more specifications. Please contact DESAPRO Engineering in order that your transit case can be tailored to meet your qualification requirements.

Are you interested in this product? Do you need additional information or individual pricing?

SHOCK AND VIBRATION ABSORBING ALUMINUM TRANSIT CASE

The MILEX case is a water and dust proofed, shock and vibration absorbing aluminum transit case for 19 inch electronics. MILEX transit cases are NATO approved and designed to meet the rigid requirements of U.S. MIL specifications and other MIL standards worldwide. Together with a large range of accessories such as cooling systems, racks, drawers and slides, MILEX aluminum transit cases represent the most comprehensive line available today for the safe packaging of mobile electronics. MILEX transit cases are made exactly to customer’s specifications. DESAPRO has developed a unique expertise in designing and custom manufacturing to deliver the right quality for your application on time.

MILEX aluminum transit cases are designed to meet the rigid requirements of MIL-STD-810G and other appropriate military standards for a product of this kind. MILEX cases are designed and manufactured to the specific requirements of environmental protection required by the equipment being contained and transported which provides the maximum protection while also affording other essential and desirable features.

The size of the MILEX case is determined by the size the equipment demands. However, due to the positioning of the DESAPRO shock mounts the space between the inner chassis and outer shell is minimized with equal or better shock and vibration properties. This feature means that the overall dimension of MILEX cases is as small as it can be without sacrificing protective characteristics.

PROTECTION AGAINST ENVIRONMENTAL STRESS:

Undesirable influences from various sources which occur during transport, storage, or operations can have a damaging effect on sensitive goods and therefore present a considerable risk. These risks are mitigated by using DESAPRO cases. DESAPRO cases protect against many environment stress’s:

Protection against climatic stress such as

Protection against internally product stress

Protection against electronic stress such as electromagnetic interference (EMI), RFI

THE MILEX ALUMINUM TRANSIT CASES CONSIST ESSENTIALLY OF THREE MAIN PARTS:

Self-supporting housing

A welded and rigid construction forms a self-supporting shell that is both light and rugged. The entire aluminum construction is shock proof and resistant to extreme temperature change, conductive and fully recyclable. Stacking feet on the bottom and indentations on the top of the housing provide stable stacking of the cases. The standard equipped cases include a pressure equalization valve. Case connections and securing the cases to any bolting pattern are available for specific applications.

Shock mounted chassis

The core of the case is a shock mounted chassis. Depending on the model and size, equipment can be fitted either from the front or the rear of the case. In order to keep the weight down and allow for optimal ventilation, the chassis are designed with large holes. The chassis is connected to the housing shell by an electrical ground strap.

Cover

All MILEX cases are protected against outside influences through a bolted cover with gasket. Easily operated closures are recessed in the housing cover and ensure a solid seal. The cover space can be used for I/O panel, windows, cable pouches, ventilation louvres etc.

TYPES

THERE ARE FOUR TYPES OF MILEX 19 INCH RACK MOUNT TRANSIT CASES

SHOCK MOUNTED

The MILEX 19’’ Transit Cases are intended for use in extreme conditions. The electronics are attached to a shock mounted chassis, not directly to the shell. A minimum of 8 shock and vibration absorbers serve to deflect any mechanical stress on the housing. After attachment of the chassis, the case is securely sealed with a cover to protect the contents against dust, sand and water.

HARD MOUNTED

The MILEX Hard mounted transit case is a standard 19 inch Case without a shock mounted chassis. It is intended for applications where vibration protection is not critical. All other protective features and outer dimensions are equivalent to the Shock mounted case.

WIRE ROPE

The MILEX Wire rope transit case is a 19 inch transit case with the chassis mounted on stainless steel spiral wire rope shock absorbers. These types of shock absorbers are used where electronics have to be protected from vibration and particularly severe shock. The wire rope shock absorbers ensure the necessary deflection, not provided by the shock absorbers in the shock mounted transit cases. Typical applications are shock protections on ship, submarines, helicopters or other aircrafts.

MILEX PRO

MILEXPRO is the newest generation of robust transit cases for the transport of sensitive electronics, IT, and measuring systems. It combines the high value by shortening the integration time of your hardware and easy access during transport and/or in operations. The closing system is unique and supported by a revolving frame system, which is guided in the X- & Y- axis thus centralizing the cover automatically. The long lasting original features of the MILEX are kept in place enabling the stacking compatibility is possible with other MILEX cases.

THE MAIN ADVANTAGES OF THE MILEXPRO ARE

FLEXIBILITY THROUGH A VARIETY OF MILEX OPTIONS

WE OFFER CUSTOM ALUMINUM TRANSIT CASE OPTIONS TO MEET YOUR SPECIFIC NEEDS

A large selection of standard accessories are available

EMI AND RFI SHIELDING OPTIONS

EMI Gasket

Electronically conductive gasket installed in the housing to provide electrical contact between the covers and the housing. This gasket also provides weather protection to the case when the covers are mounted.

EMI Frame

A special EMI thight fame manufactured with alodine aluminum can be used for additional EMI protection. This gives the maximum protection to the electronics in the case. In order to dissipate heat produced by the electronics, the walls of the frame have 3mm (0,12’’) holes, average distance between holes is 4mm (0,14’’).

EMI conductive skirt seal

To eliminate the risk of water or dust contamination to the interior of the case when the covers are removed, a flexible seal between the chassis and housing can be specified and fitted. This flexible skirt seal does not affect the anti vibration characteristics of the case. Sealing of the space between the housing and the frame results in IP 65 protection. The skirt seal is electrically conductive.

MILEX DESIGN CHARACTERISTICS AND FEATURES

Variety of Standard Sizes (DIN41494 / IEC297)

MILEX case performance is dependent on a wide-variety of variables such as payload weight, payload center-of-gravity, payload fragility, payload mounting, payload fastening, test durations, test sequencing, customer pass/fail criteria and many more specifications. Please contact DESAPRO Engineering in order that your transit case can be tailored to meet your qualification requirements.