Photos are for informational purposes only. View product specification

please use latin characters

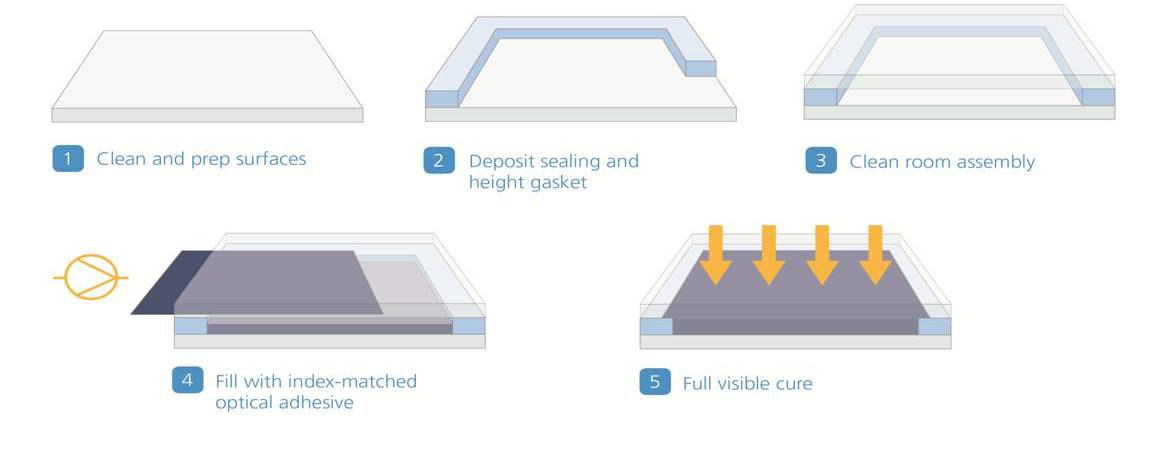

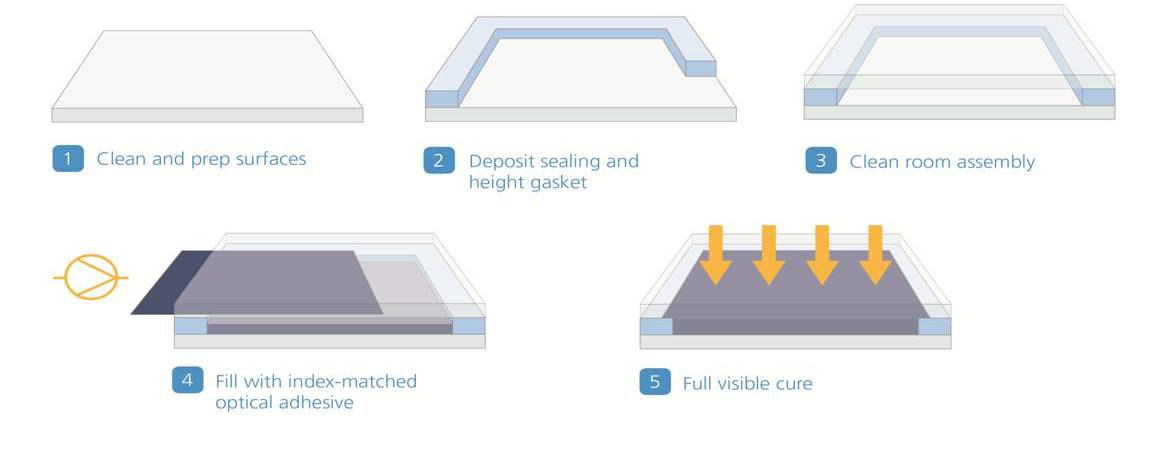

| Company DACPOL with partner OPTICA FILTERS are start promoting new service call OPTICAL BONDING. That technology provide high quality solution for bonded display with glass or other cover. Using our background of over 25 years in display enhancement and other display bonding options Optical Filters has developed Viz-Bond®, a wet bonding system that cures to a gel, to deliver a cost effective, scalable system in which the components are processed at ambient temperature without the use of vacuum, temperature, pressure and need for multiple tooling. Viz-Bond® cures within the wave length range of 390-500nm and can therefore cure through a polarizer and materials containing UV inhibitors. The system can also cure behind edge masks up to a 20mm (3/4") width. |

|

|

|

Enviromental performancesTemperature Stable under multiple ESS cycles between -55°C to +85°C with ramp rates of 3-5°C/min and dwell times at extremes of 30 minutes (minimum) Humidity No change after exposure to 95% R.H. at 70°C for a minimum of 50 hours UV/solar exposure Fill adhesive and sealing gasket are stable and show minimal changes in transmission and L.A.B. values following extensive simulated UV/Solar Exposure. Testing to MIL-STD-810g / ASTM G151 is on-going in our own certified solar chamber. Chemical Resistance Viz-Bond® is stable with most silicone, polyurethane and polysulphide adhesive sealants but may be attacked by MEK, acetone, toluene or materials which utilize similar solvent systems. |

Mechanical performanceImpact resistance Enhances laminate performance to exceed the boot impact MIL-STD - 3122 and the Wrench Impact Ball drop test (1" diameter steel ball dropped from 20-25" - 6 impacts) Shock absorption Viz-Bond® laminates of un-tempered float glass absorb 8+ times the energy of a standard dry film laminate before failure Vibration tolerance In accordance with MIL-STD-810F-514.5 Adhesion - Pull Complies with ASTM-4541, EN13144, ISO-16276-1 using a Elcometer 601 qualified test apparatus Adhesion - Sheer No failure of a bond to a 10.4" display with a 1000g weight suspended vertically at 85°C for 8 hours and >1000 hours at ambient Bond thickness 0.7mm +0.2/-0.1mm typical bond thickness Measured from the surface of the display bezel (or face of the display if the bezel is not present) to the rear surface of the display enhancement stack. |

Material propertiesMaterial type Low viscosity, UV-visible curing proprietary Alkyl Urethane Optical

Cure range 390-500 nm Cure time <3 minutes with exposure to 3-5milliwatts/sq cm at ambient temperatures Viscosity (uncured) <50 cps (Allows Viz-Bond® to be pumped into a fill cavity high rates with low pressure) Material uniformity A chemical fingerprint of each batch is obtained using FTIR spectrophotometer. All batches must fall within the specified finger print with a tolerance of +/-2% Hardness / Softness <15 Durometer scale A) Elasticity Young's modulus <180KPa Shrinkage <5% by volume |

|

Are you interested in this product? Do you need additional information or individual pricing?

| Company DACPOL with partner OPTICA FILTERS are start promoting new service call OPTICAL BONDING. That technology provide high quality solution for bonded display with glass or other cover. Using our background of over 25 years in display enhancement and other display bonding options Optical Filters has developed Viz-Bond®, a wet bonding system that cures to a gel, to deliver a cost effective, scalable system in which the components are processed at ambient temperature without the use of vacuum, temperature, pressure and need for multiple tooling. Viz-Bond® cures within the wave length range of 390-500nm and can therefore cure through a polarizer and materials containing UV inhibitors. The system can also cure behind edge masks up to a 20mm (3/4") width. |

|

|

|

Enviromental performancesTemperature Stable under multiple ESS cycles between -55°C to +85°C with ramp rates of 3-5°C/min and dwell times at extremes of 30 minutes (minimum) Humidity No change after exposure to 95% R.H. at 70°C for a minimum of 50 hours UV/solar exposure Fill adhesive and sealing gasket are stable and show minimal changes in transmission and L.A.B. values following extensive simulated UV/Solar Exposure. Testing to MIL-STD-810g / ASTM G151 is on-going in our own certified solar chamber. Chemical Resistance Viz-Bond® is stable with most silicone, polyurethane and polysulphide adhesive sealants but may be attacked by MEK, acetone, toluene or materials which utilize similar solvent systems. |

Mechanical performanceImpact resistance Enhances laminate performance to exceed the boot impact MIL-STD - 3122 and the Wrench Impact Ball drop test (1" diameter steel ball dropped from 20-25" - 6 impacts) Shock absorption Viz-Bond® laminates of un-tempered float glass absorb 8+ times the energy of a standard dry film laminate before failure Vibration tolerance In accordance with MIL-STD-810F-514.5 Adhesion - Pull Complies with ASTM-4541, EN13144, ISO-16276-1 using a Elcometer 601 qualified test apparatus Adhesion - Sheer No failure of a bond to a 10.4" display with a 1000g weight suspended vertically at 85°C for 8 hours and >1000 hours at ambient Bond thickness 0.7mm +0.2/-0.1mm typical bond thickness Measured from the surface of the display bezel (or face of the display if the bezel is not present) to the rear surface of the display enhancement stack. |

Material propertiesMaterial type Low viscosity, UV-visible curing proprietary Alkyl Urethane Optical

Cure range 390-500 nm Cure time <3 minutes with exposure to 3-5milliwatts/sq cm at ambient temperatures Viscosity (uncured) <50 cps (Allows Viz-Bond® to be pumped into a fill cavity high rates with low pressure) Material uniformity A chemical fingerprint of each batch is obtained using FTIR spectrophotometer. All batches must fall within the specified finger print with a tolerance of +/-2% Hardness / Softness <15 Durometer scale A) Elasticity Young's modulus <180KPa Shrinkage <5% by volume |

|