-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

- Cables for extreme applications

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

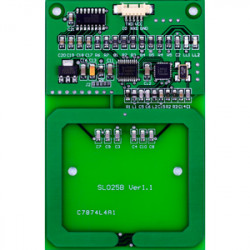

Industrial RFID

Radio-Frequency Identification (RFID)

Radio-Frequency Identification (RFID) is a short-range, automatic, and contactless communication method that utilizes radio-frequency electromagnetic fields to receive and read information about an object from data stored on a tag.

RFID technology is commonly used to track and identify assets and devices using an antenna. RFID has a range of 1 to 12 meters and a speed of 640 kbps. It is a form of wireless communication that is rapidly replacing wired technology and becoming the primary means of communication in everyday life, manufacturing plants, services, and commercial sectors.

RFID is used to exchange data between two entities – a reading device and a tag. RFID tags and readers must be tuned to the same frequency to enable mutual communication.

RFID Frequencies

Currently, RFID technology – radio-frequency identification – utilizes three frequency standards: LF, HF, and UHF.

Low frequency (LF)

Uses frequencies ranging from 30 to 300 kHz. It allows for tag reading from a distance of up to 10 cm.

High frequency (HF)

Theoretically covers the frequency range from 3 to 30 MHz, but according to the ISO standard, RFID technology uses 13.56 MHz. It allows for data reading from a distance of up to approximately 1.5 meters.

Ultra-high frequency (UHF)

Ranges from 300 MHz to 3 GHz, but in systems and devices, the frequency is usually 860 to 960 MHz. It allows for reading and writing at a distance of up to 15 meters.

RFID Standards

There are several RFID standards, divided according to their technical implementation – encoding type, tag memory size, transmission speed, tag discrimination within the reader's range, etc.:

- Iris – one of the first RFID standards; based on FM transmission. Primarily used in commerce.

- Unique – the simplest and most common standard used for access control and time recording.

- Q5 – uses programmable tags that respond, for example, to a specific password.

- Hitag – for industrial applications; allows for writing and reading messages on tags. Used in payment collection systems, product labeling, and animal identification.

- Mifare – enables the use of both simple memory tags and highly complex ones, containing processors supporting encryption. Used in bank cards, identification cards, and tickets.

- Icode – characterized by very flat tags. Used in retail, libraries, shipment flow control, and inventory management.

Principle of Operation of an RFID-Based System

RFID technology enables the reading and transfer of data, as well as the electronic powering of data-storing chips and tags. This system allows for the reading of data from chips/special tags that are positioned at a specific distance from an RFID reader or antenna. The reader uses an antenna to generate an electromagnetic wave. The same or a different antenna then receives the electromagnetic waves, which are decoded and read.

A basic RFID system consists of:

- a reader containing a transmitter, receiver, and decoder;

- a transmitting/receiving antenna or two antennas: transmitting and receiving;

- a system of labels called transponders or tags, consisting of: an electronic circuit, which is an integrated circuit without a housing, or an antenna.

RFID Applications

RFID radio communication technology is a widely used solution and is constantly evolving, supporting an increasing number of areas, not only industrial, but also commercial, service, construction, and home applications.

Trade

The most common RFID applications in trade involve tracking the flow of goods from the manufacturer to the customer. RFID technology supports supply chain management by identifying product ranges, controlling warehouse and store inventory, verifying the positioning of goods on shelves, and speeding up and simplifying customer service at checkouts or self-checkout stations.

Management and Monitoring of Logistics and Warehouse Processes

RFID solutions are also widely used in transport, goods storage, and turnover management. They support and enable monitoring the location and flow of goods through the use of special RFID tags, for example, by placing them on vehicles or products. Using RFID technology for logistics and warehouse management speeds up the loading and unloading of goods and verifies product range and inventory levels.

RFID systems are also successfully used for returnable packaging management. They help monitor the condition of pallets, crates, beer kegs, and other types of containers, as well as accounting for returnable packaging, e.g., in the event of loss, reducing costs and errors in recording goods and inventory levels. An additional advantage of such systems is the fact that RFID tags can be reused.

RFID in Industry

Many industrial applications utilize RFID systems in production processes, synchronization, and monitoring. Using this type of radio communication allows for work automation by, for example, placing RFID tags on products, machines, vehicles, and tools to quickly identify, monitor, count, etc.

Construction and RFID Systems

The most common use of RFID in construction is the monitoring of valuable construction equipment. RFID tags placed on machines and tools help monitor and record equipment status, as well as prevent unwanted incidents such as theft of tools and materials.

RFID can also be used in the form of personal identifiers, such as cards with an embedded chip (access cards, city cards, parking cards). They record activities, authorize entry, and identify cardholders, among other things. This solution is often used for time and attendance recording or securing premises, resources, and information from unauthorized access. They can also control vehicle traffic in private parking lots, manage the opening of gates and barriers, and operate in road toll systems – allowing vehicles to pass through a designated lane without having to stop.

RFID in Medicine

Continuous monitoring of equipment, medical supplies, documentation, and patients.

RFID in the IT Sector

Location of IT equipment, servers, computers, etc., and securing confidential data.

Advantages, Disadvantages, and Threats of Radio Communication

Despite its usefulness and widespread use in many industrial sectors, RFID remains a controversial solution that can pose security and privacy threats, for example, by facilitating access to confidential data stored on cards or causing the loss of customer anonymity.

RFID Advantages

- No need for direct contact between the tag and the reader - remote reading;

- Ability to read multiple tags simultaneously - even hundreds of tags in a few seconds;

- High durability and resistance of tags; resistance to harsh operating conditions, such as dirt, dust, and sunlight;

- Reusable and editable data;

- Discreet tag location;

- Process automation; monitoring.

RFID Disadvantages

- Costs of implementation, RFID readers, tags, and equipment.

- A certain level of experience and knowledge is required to effectively implement and operate an RFID system.

- The need to encrypt sensitive data - a security risk.

- RFID is unprofitable when used, for example, for labeling small and quickly worn-out items.

As with any technology, it is important to consider all the pros and cons: familiarize yourself with RFID's capabilities, examine available solutions, and determine your needs to ultimately decide whether this method meets your expectations.

Related products

Related posts

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

Leave a comment