-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

- Cables for extreme applications

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

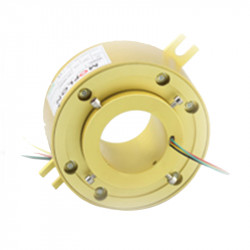

Slip Rings and Rotary Joints – Applications

The aerospace, defense, and space industries rely on precise components that ensure continuous operation even under the most demanding conditions. One of the key elements of such systems are slip rings and rotary joints – solutions that enable the transfer of electrical power, control signals, and data between stationary and rotating parts.

Without these components, radars, guidance systems, space robots, or control mechanisms in airplanes and satellites could not operate. Thanks to slip rings and rotary joints, it is possible to maintain uninterrupted electrical and signal communication in devices performing rotational motion – while maintaining high precision and durability.

Their design and specifications are tailored to the specifics of the application – from microsignals in measurement systems to high-power transfer in military equipment. In industries where reliability means safety, slip rings and rotary joints are an essential link between technology and operational effectiveness.

The role of slip rings and rotary joints in modern industry

In every industry where precision and continuity of work matter, there is one common denominator — rotational motion. Rotational motion is present in many advanced devices: from radars and wind turbines, through optical systems, to industrial robots. However, to ensure this motion does not interrupt the transmission of energy or signals, slip rings and rotary joints are required.

These are small but crucial components that allow current, data, and control signals to be transferred between the stationary and rotating parts of a device — without the risk of connection loss. In practice, this means that a thermal imaging camera can rotate freely, a radar can track a target across its full range, and a generator rotor or robot manipulator can operate without tangled cables.

Slip rings and rotary joints come in many variants – from miniature signal models to high-current solutions capable of transferring hundreds of amperes. Depending on the application, they differ in:

- current range (from a few milliamps to kiloamps),

- operating voltage (from a few volts to kilovolts),

- signal frequency (up to hundreds of megahertz).

In modern installations, hybrid rotary joints are increasingly used, combining electrical, signal, fiber optic, and hydraulic paths in a single unit. This allows simultaneous transmission of energy, data, and process media — smoothly, safely, and fully controlled.

This is why slip rings and rotary joints are now an integral part of modern technologies — from precision industry and energy, to aerospace and space.

Applications in aviation and defense

Aviation and the defense sector are some of the most demanding areas for engineering. Every component matters, and the reliability of a component often determines the safety of the entire system. Devices operate under extreme conditions – high loads, vibrations, rapid temperature changes, and limited service opportunities. In such environments, slip rings and rotary joints must operate flawlessly for thousands of hours.

Radar systems

Modern radars, both ground-based and airborne, use rotary joints to transfer high-frequency signals and power to rotating antennas. The quality of these connections affects targeting accuracy and communication reliability. Military radars often use slip rings with RF and fiber optic paths, ensuring stable data transfer even at very high rotational speeds.

Guidance systems and FLIR optics

In optoelectronic systems, such as FLIR (Forward Looking Infrared) units, slip rings allow cameras and sensors to rotate freely across a full 360° range. This enables smooth target tracking and real-time image transmission without signal loss. In these applications, data transmission stability, low noise, and wide operating temperature range are critical.

Rotor blade de-icing systems

In helicopters and rotor-driven aircraft, high-current slip rings power rotor blade de-icing systems. Their construction must withstand strong vibrations, temperature fluctuations, and environmental factors. High sealing, resistance to moisture and dust, and stable transfer of large operating currents are required.

Tank turrets and defense systems

In military vehicles, slip rings and rotary joints play a key role in communication between the hull and the rotating turret. They allow simultaneous transmission of control signals, targeting system data, power, and video. Here, mechanical strength, shock resistance, and reliability in field conditions are crucial.

Applications in space and satellite industry

Space exploration is an area where there is no room for error. Every element of a satellite, probe, or research module must operate reliably for many years, often in conditions where repair is impossible. Slip rings and rotary joints play a key role in the design of space devices — ensuring smooth transfer of power, signals, and data between parts that must rotate or move relative to each other.

Satellites and positioning systems

In communication, observation, and navigation satellites, slip rings enable continuous connectivity between stationary and moving parts – for example, between the satellite body and directional antennas or optical positioning systems. They allow precise antenna orientation in space without interruptions in data, telemetry signals, or power transmission.

Space robots and research mechanisms

Robots used in planetary missions, e.g., rovers and manipulator arms, are equipped with numerous rotary mechanisms that must operate in extreme conditions – low pressure, low temperature, and high dynamic loads. Slip rings in such devices ensure reliable transfer of control signals and power to moving joints, allowing the robot to move, collect samples, or operate tools with surgical precision.

Solar panel systems

One of the most common uses of slip rings in space is in rotating photovoltaic panel systems. To maximize solar energy use, panels must continuously align with the light source. Slip rings enable continuous power and communication between rotating panels and the satellite’s central power system – without the risk of tangled cables.

Requirements for space components

- low weight – every gram affects launch costs,

- high reliability – components must operate for years without maintenance,

- resistance to vacuum, radiation, and extreme temperatures,

- minimal friction and wear to maintain stable electrical parameters over time.

Therefore, space designs use special composite materials, gold-plated contacts, and vacuum lubricants, and each slip ring is fully tailored to the mission.

Cooling systems for radars and military equipment

Modern radar systems and weaponry generate large amounts of heat, which must be efficiently dissipated to maintain operational stability and measurement accuracy. With high-power technology development, traditional cooling methods — such as air or single-phase liquid systems — are no longer sufficient.

Rotary joints in liquid cooling systems

In radar and military systems, where moving parts (e.g., rotating antennas, sensor heads, or vehicle turrets) need cooling, rotary joints for liquids play an important role. They enable safe and leak-proof flow of the cooling medium between stationary and rotating parts without risk of leakage or pressure drop.

Rotary joints are often integrated with electrical slip rings, forming compact modules that simultaneously transmit power, control signals, and liquid cooling. Such a combination is standard in modern radars, where reliability and resistance to combat conditions are critical.

Stability and efficiency of radar systems

Proper cooling directly affects radar measurement accuracy and the lifespan of electronic components. High temperatures can cause frequency drift, signal transmission errors, or damage to high-power components.

- full sealing and high-pressure resistance,

- resistance to vibration, shocks, and temperature changes,

- capable of transferring high-frequency signals and high currents,

- minimal torque to avoid affecting antenna movement precision.

Other industrial sectors using slip rings

Slip rings and rotary joints are also used in industry — from automation, through energy, to transport. In industrial automation and robotics, they allow uninterrupted transfer of control signals and power to moving robot arms, avoiding cable tangling.

In wind energy, they transfer power and control signals between the rotor and stationary generator, ensuring durability and resistance to changing weather conditions. In maritime and transport industries, resistance to corrosion, vibration, and harsh environments is crucial.

Although the principle of operation remains similar, the construction differs depending on the sector: in aviation and space, low weight and resistance to extreme conditions are important; in industry — durability, larger mechanical tolerances, and resistance to dust and moisture.

Selecting the right solution – what to consider

Choosing the right slip ring or rotary joint can determine system reliability and safety. When selecting a component, consider:

- Technical parameters: current and operating voltage, number of circuits, IP protection class,

- Environmental conditions: temperature, humidity, vibration, pressure,

- Need for customization: every system requires a specific solution tailored to electrical, mechanical, and environmental requirements.

Summary

Proper selection of slip rings and rotary joints is the foundation of reliability and safety of modern systems — in aviation, space, defense, and industry.

DACPOL offers a wide range of high-quality electromechanical components, including slip rings, rotary joints, and products from the renowned brand MOFLON. Our experience and technical consultancy allow you to select a solution perfectly suited to your needs, regardless of industry sector or application requirements.

Contact our team of experts to get support in selecting the right solution and ensure the reliability of your system from day one.

Related products

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Leave a comment