Трябва да сте влезли в

Category

Снимките са само с информационна цел. Вижте спецификацията на продукта

please use latin characters

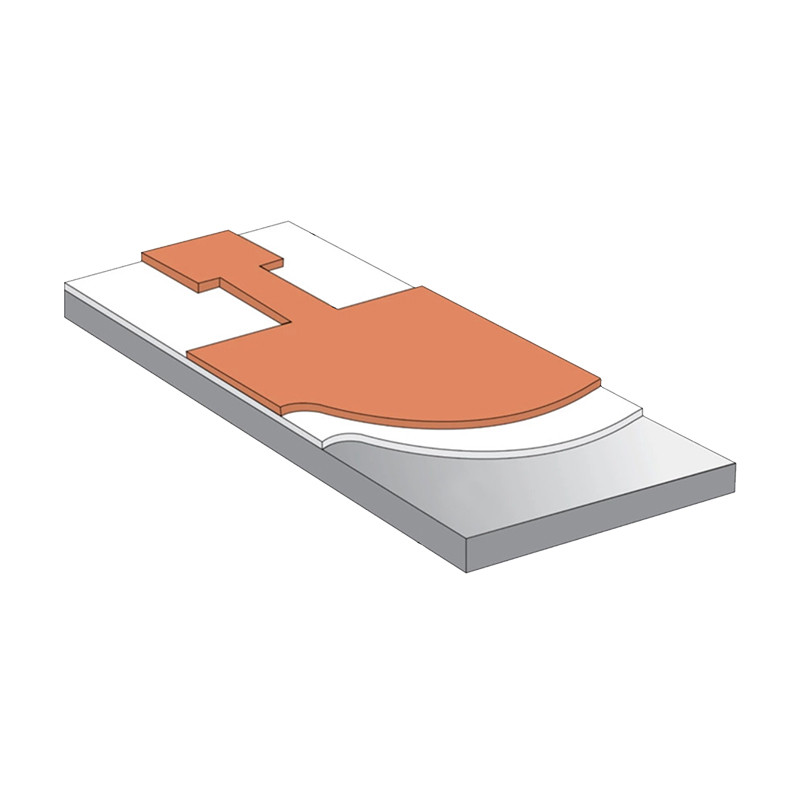

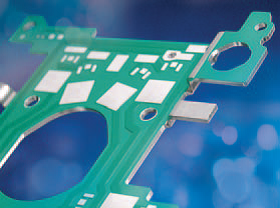

Thermal Clad is a versatile substrate allowing circuit boards to be configured for shapes, bends and multiple thicknesses. In this motor control application, the dielectric has been selectively removed and the metal formed with three-dimensional features.

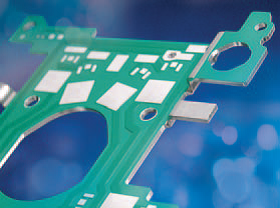

Additional Thermal Clad benefits:

• Increased power density

• Extend the life of dies

• Improved product thermal and mechanical performance

• Better use of surface mount technology

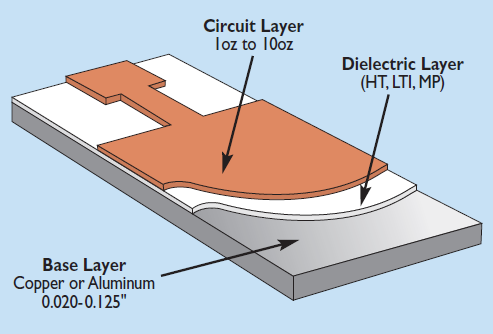

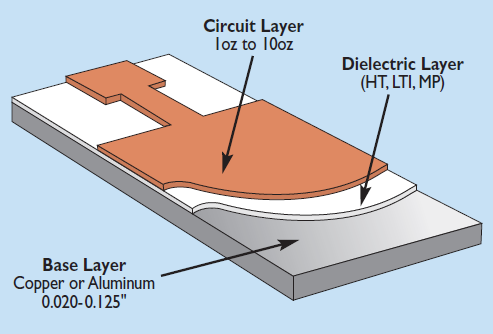

Anatomy of a Thermal Clad Board:

1. Base layer Copper 0,51 - 4,83 mm oa Aluminium 0,51 - 3,18 mm.

2. Dielectric layer – HPL, HT, LM, MP.

3. Circuit layer – 35 um – 350 um.

Parameters:

|

Type

|

Thickness

(10-3in/10-6m) |

Impedance

(oC/W) |

Conductivity

(W/m-k) |

Operating

(VAC) |

Breakdown

(kVAC) |

HT-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.0

|

HT-07006 |

6/150

|

0.70

|

2.2

|

960

|

11.0

|

LTI-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.5

|

LTI-06005 |

5/125

|

0.60

|

2.2

|

480

|

9.5

|

MP-06503 |

3/75

|

0.65

|

1.3

|

120

|

8.5

|

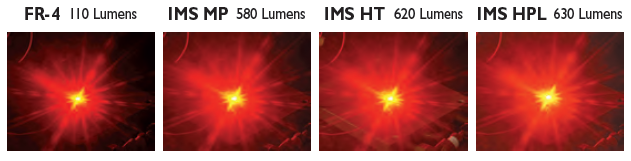

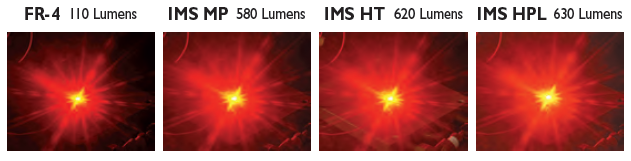

Light output of the same LED die on different circuit board materials at a maintained die temperature of 80ºC.

Интересувате ли се от този продукт? Имате ли нужда от допълнителна информация или индивидуални цени?

Трябва да сте влезли

Thermal Clad is a versatile substrate allowing circuit boards to be configured for shapes, bends and multiple thicknesses. In this motor control application, the dielectric has been selectively removed and the metal formed with three-dimensional features.

Additional Thermal Clad benefits:

• Increased power density

• Extend the life of dies

• Improved product thermal and mechanical performance

• Better use of surface mount technology

Anatomy of a Thermal Clad Board:

1. Base layer Copper 0,51 - 4,83 mm oa Aluminium 0,51 - 3,18 mm.

2. Dielectric layer – HPL, HT, LM, MP.

3. Circuit layer – 35 um – 350 um.

Parameters:

|

Type

|

Thickness

(10-3in/10-6m) |

Impedance

(oC/W) |

Conductivity

(W/m-k) |

Operating

(VAC) |

Breakdown

(kVAC) |

HT-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.0

|

HT-07006 |

6/150

|

0.70

|

2.2

|

960

|

11.0

|

LTI-04503 |

3/75

|

0.45

|

2.2

|

120

|

6.5

|

LTI-06005 |

5/125

|

0.60

|

2.2

|

480

|

9.5

|

MP-06503 |

3/75

|

0.65

|

1.3

|

120

|

8.5

|

Light output of the same LED die on different circuit board materials at a maintained die temperature of 80ºC.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Напишете свой отзив

Review sent

Your review cannot be sent