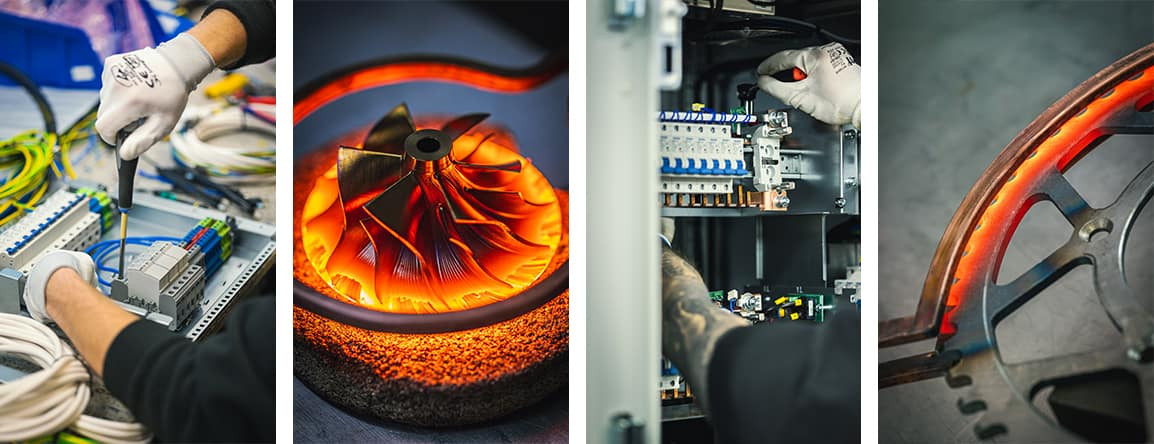

Článek představuje cestu od základů elektroniky až po tvorbu pokročilejších zařízení, ukazující roli výukových sad, elektronických součástek a výkonových modulů. Vysvětluje, jak stavebnice pro vlastní montáž rozvíjejí praktické dovednosti a jak správně zvolené napájecí moduly, řadiče a výkonové prvky umožňují vytvářet jak hobby projekty, tak řešení blízká průmyslové elektronice.

Podsestavy pro výkonovou elektroniku - průmyslová automatizace - elektronika - energie - elektrotechnika

kategorie produktů

Zobrazit všechny kategorieNejnovější příspěvky

-

Průmyslové LED osvětlení vs tradiční – rozdíly, výhody a výzvy pro moderní výrobní halyRead more

Článek představuje hlavní rozdíly mezi průmyslovým LED osvětlením a tradičními světelnými zdroji, jako jsou sodíkové nebo rtuťové lampy. Zabývá se klíčovými parametry ovlivňujícími práci ve výrobních halách – energetickou účinností, životností, kvalitou světla, provozními náklady a ekologickými aspekty. Zdůrazňuje rostoucí roli LED technologie při modernizaci průmyslových objektů, výhody jejího použití a situace, kdy lze stále využívat tradiční lampy. Článek ukazuje, proč se LED stávají standardem v moderních výrobních závodech a skladech.

-

Průmyslová a energetická transformace – jak výkonová elektronika pohání novou technologickou éruRead more

Tento článek ukazuje, jak se výkonová elektronika stala klíčovým motorem moderní energetické a průmyslové transformace. Popisuje její roli při integraci obnovitelných zdrojů energie, ukládání a přeměně energie, stabilizaci sítí a automatizaci průmyslových procesů. Text představuje jak současné aplikace výkonové elektroniky, tak i perspektivy jejího rozvoje, zdůrazňující význam pro udržitelný rozvoj, digitalizaci infrastruktury a implementaci Průmyslu 4.0.

![Komponenty pro nebezpečné oblasti a výbušné atmosféry [Ex]](https://www.dacpol.eu/c/6823-catsmal_default/komponenty-pro-nebezpecne-oblasti-a-vybusne-atmosfery-ex-.jpg)