Musíte být přihlášen

Category

Fotografie slouží pouze pro informační účely. Zobrazit specifikaci produktu

please use latin characters

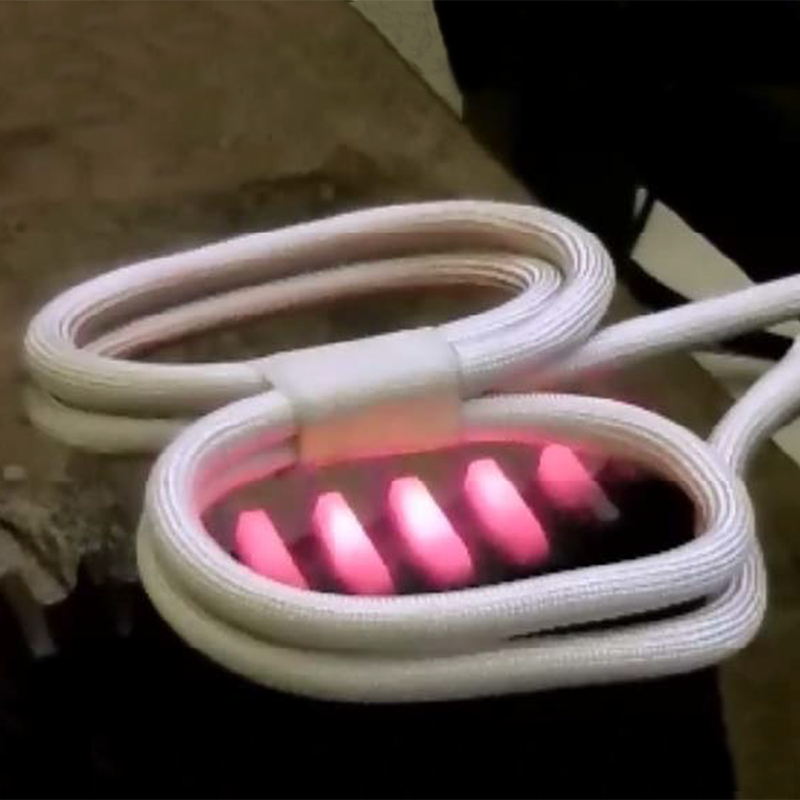

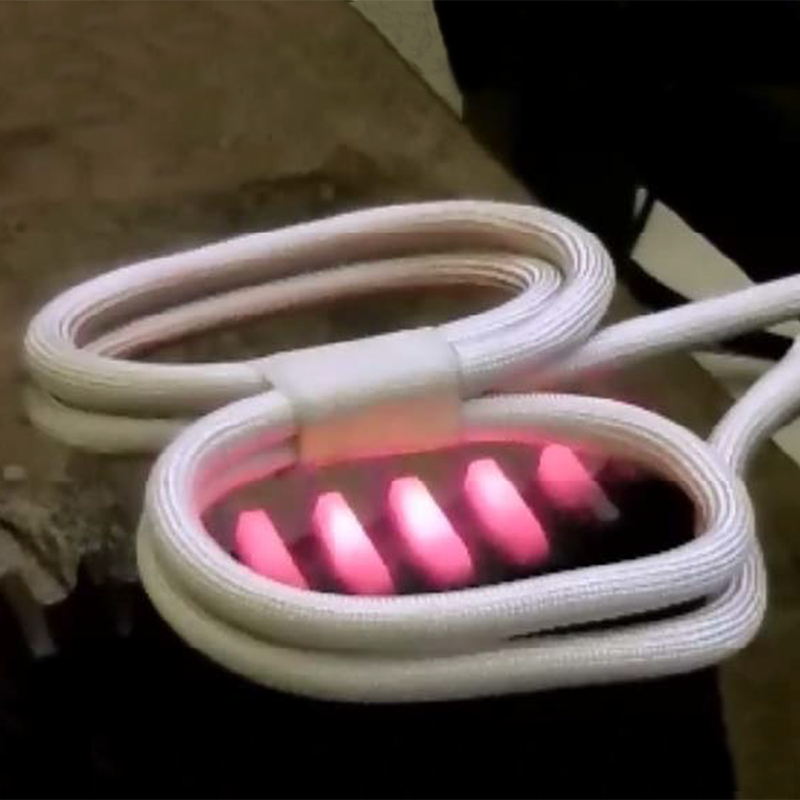

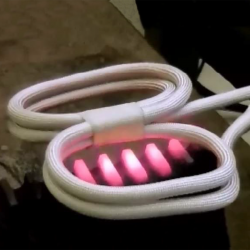

Objective: Heating the teeth of a large saw blade for a hardening application; the objective is to reduce the heating time.

Equipment:

Frequency: 134 kHz

Material:

Temperature: 1650 ºF (899 ºC)

Testing:

Benefits:

Máte zájem o tento produkt? Potřebujete další informace nebo individuální ceny?

musíš být přihlášen

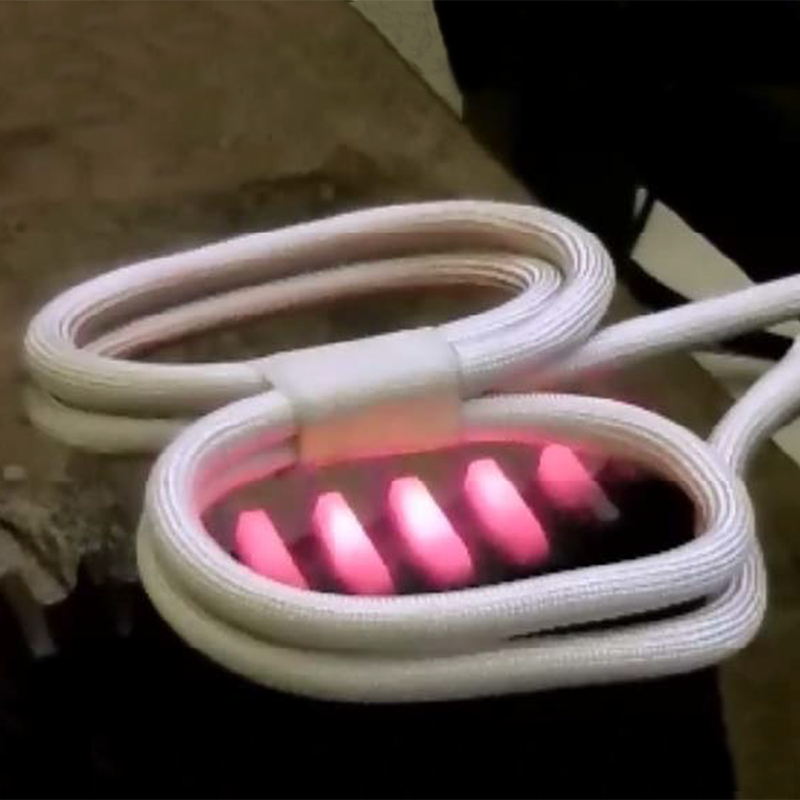

Objective: Heating the teeth of a large saw blade for a hardening application; the objective is to reduce the heating time.

Equipment:

Frequency: 134 kHz

Material:

Temperature: 1650 ºF (899 ºC)

Testing:

Benefits:

Vaše hodnocení nelze odeslat

Nahlásit komentář

Zpráva odeslána

Váš podnět nelze odeslat

Napište svůj názor

Zkontrolovat před odesláním

Vaši recenzi nelze odeslat