Musíte být přihlášen

Category

Fotografie slouží pouze pro informační účely. Zobrazit specifikaci produktu

please use latin characters

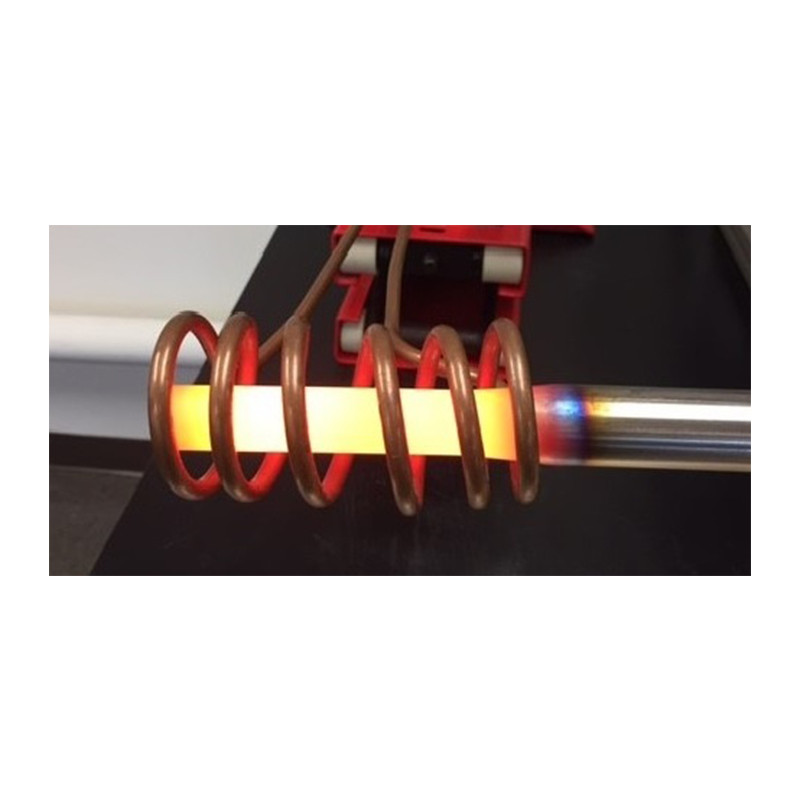

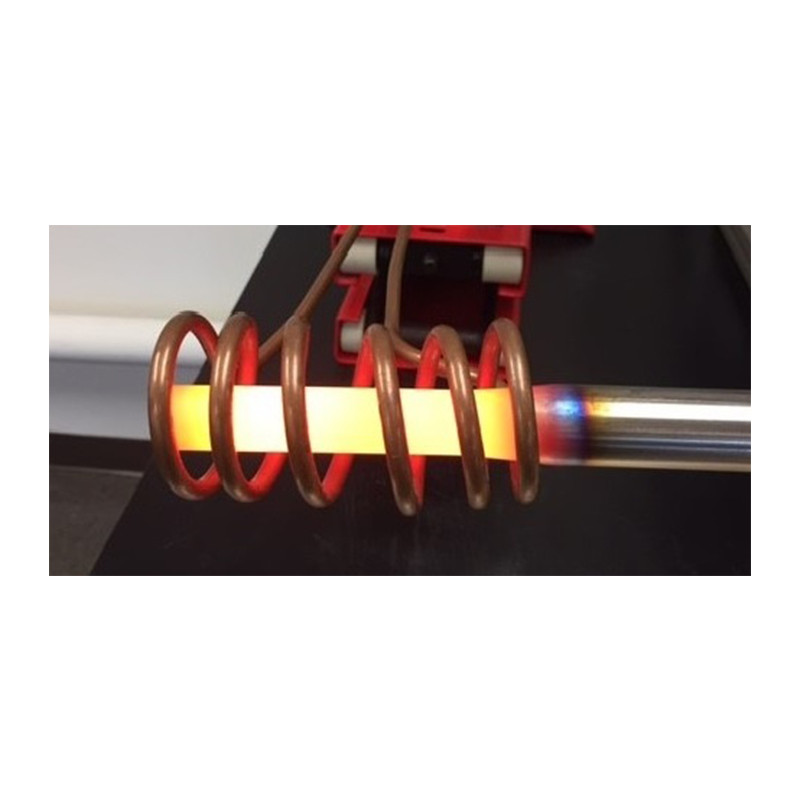

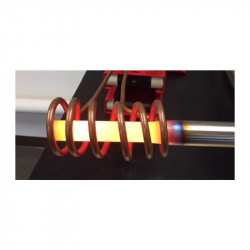

Objective: To heat a stainless steel tube while avoiding oxidation for an annealing application; the end product is a handle for a dental tool.

Material: Steel tube, hydrogen gas, bell jar and fixture

Temperature: 1038 °C

Frequency: 270 kHz

Equipment: Ambrell EASYHEAT LI 4 kW, 150-400 kHz induction heating system equipped with a remote workhead containing two 1.5 μF capacitors for a total capacitance of 0.75 μF, single position three-turn helical induction heating coil.

Process: The stainless steel tube was placed inside the tube and connected to hydrogen. A bell jar was placed over the tube to trap the hydrogen gas. Hydrogen was allowed to flow into the bell jar for one minute. Power was then turned on and the part began to heat. The part achieved annealing temperature within five seconds. Power was turned off and the part was allowed to cool for one minute.

Results:

Máte zájem o tento produkt? Potřebujete další informace nebo individuální ceny?

musíš být přihlášen

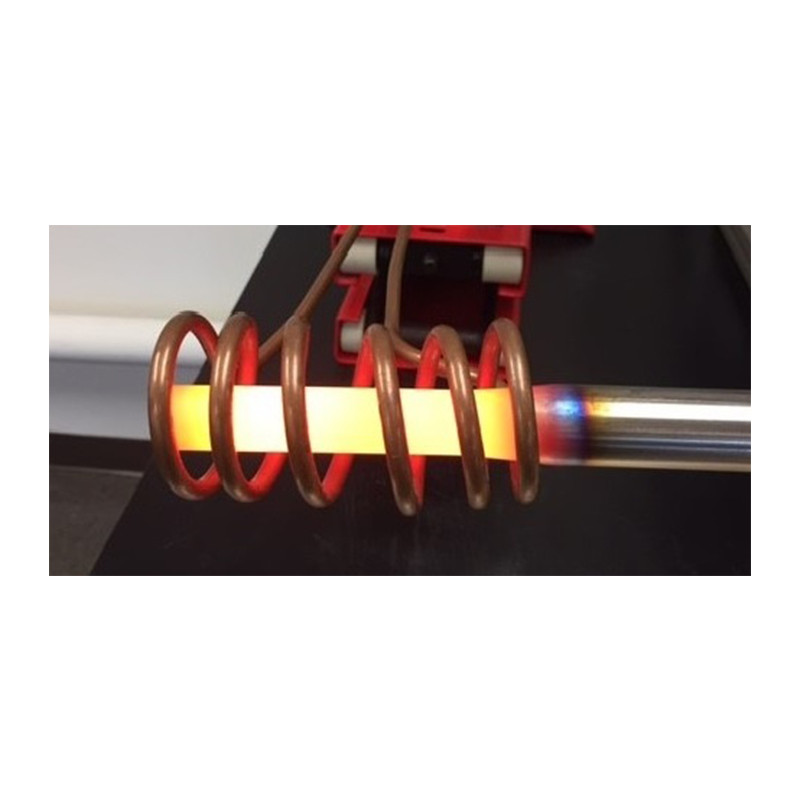

Objective: To heat a stainless steel tube while avoiding oxidation for an annealing application; the end product is a handle for a dental tool.

Material: Steel tube, hydrogen gas, bell jar and fixture

Temperature: 1038 °C

Frequency: 270 kHz

Equipment: Ambrell EASYHEAT LI 4 kW, 150-400 kHz induction heating system equipped with a remote workhead containing two 1.5 μF capacitors for a total capacitance of 0.75 μF, single position three-turn helical induction heating coil.

Process: The stainless steel tube was placed inside the tube and connected to hydrogen. A bell jar was placed over the tube to trap the hydrogen gas. Hydrogen was allowed to flow into the bell jar for one minute. Power was then turned on and the part began to heat. The part achieved annealing temperature within five seconds. Power was turned off and the part was allowed to cool for one minute.

Results:

Vaše hodnocení nelze odeslat

Nahlásit komentář

Zpráva odeslána

Váš podnět nelze odeslat

Napište svůj názor

Zkontrolovat před odesláním

Vaši recenzi nelze odeslat