Category

Фотографии предназначены только для информационных целей. Посмотреть спецификацию продукта

please use latin characters

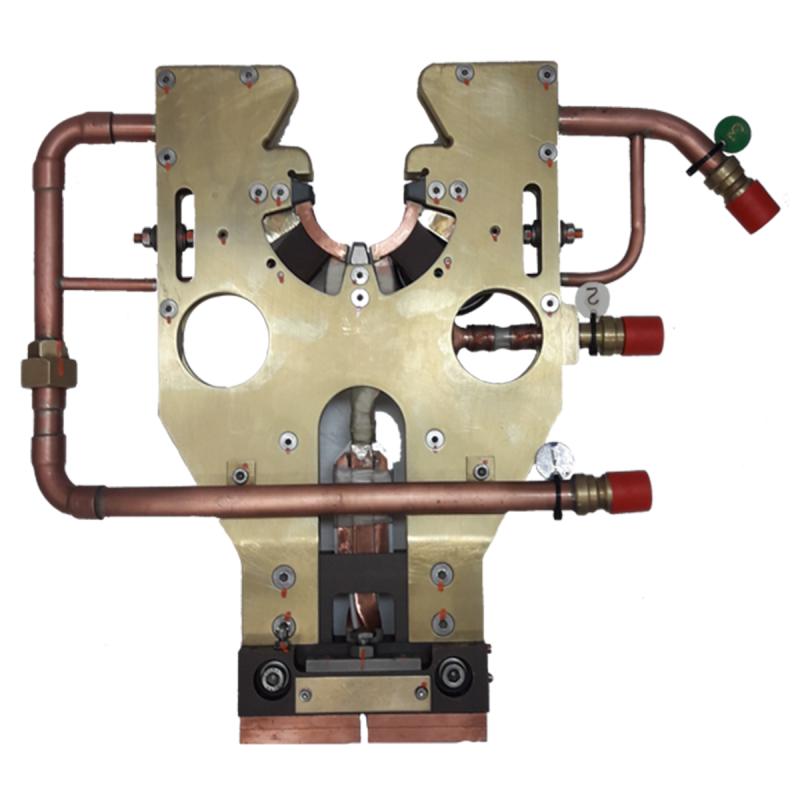

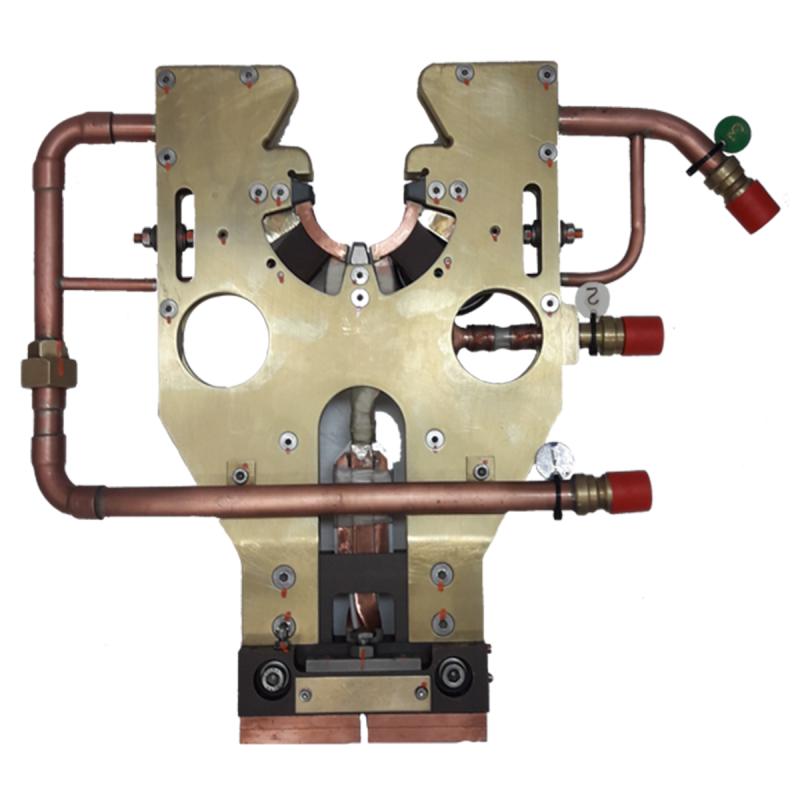

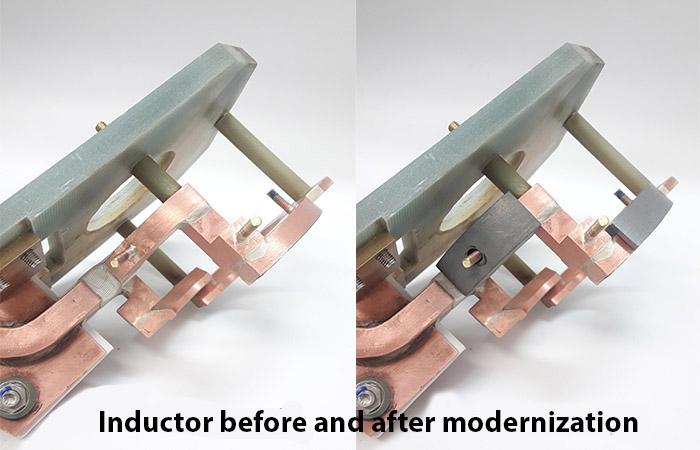

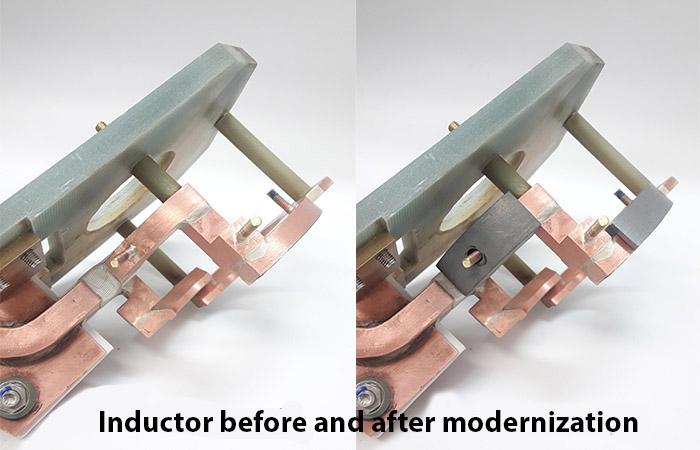

The modernization of the inductor is the introduction of changes in its design aimed at:

Example:

The change in the shape of the inductor head and the use of magnetic field concentrators allowed to increase the precision and reduce heating in non-hardened zones, increase the efficiency of the process by more precisely focusing energy to the hardened area, reducing the heating time while maintaining the same value of power absorbed.

Вы заинтересованы в этом продукте? Вам нужна дополнительная информация или индивидуальные расценки?

Вы должны быть зарегистрированы

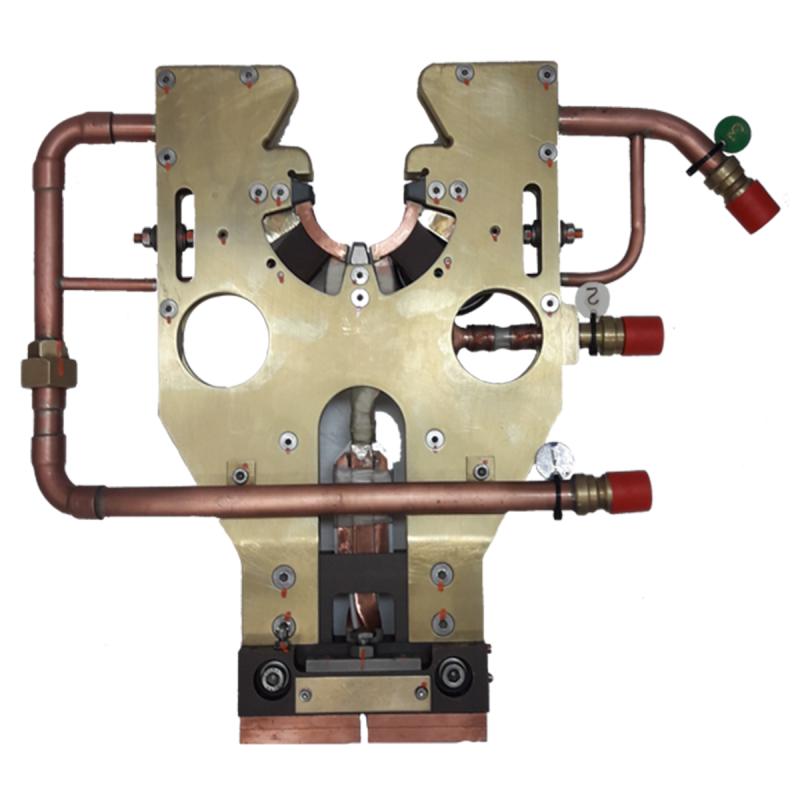

The modernization of the inductor is the introduction of changes in its design aimed at:

Example:

The change in the shape of the inductor head and the use of magnetic field concentrators allowed to increase the precision and reduce heating in non-hardened zones, increase the efficiency of the process by more precisely focusing energy to the hardened area, reducing the heating time while maintaining the same value of power absorbed.

The use of induction heating in the manufacture of industrial equipment

The use of induction heating in the manufacture of industrial equipment

Не удаётся отправить вашу оценку отзыва

Пожаловаться на комментарий

Жалоба отправлена

Не удаётся отправить вашу жалобу

Оставьте свой отзыв

Отзыв отправлен

Не удаётся отправить отзыв