Category

Фотографии предназначены только для информационных целей. Посмотреть спецификацию продукта

please use latin characters

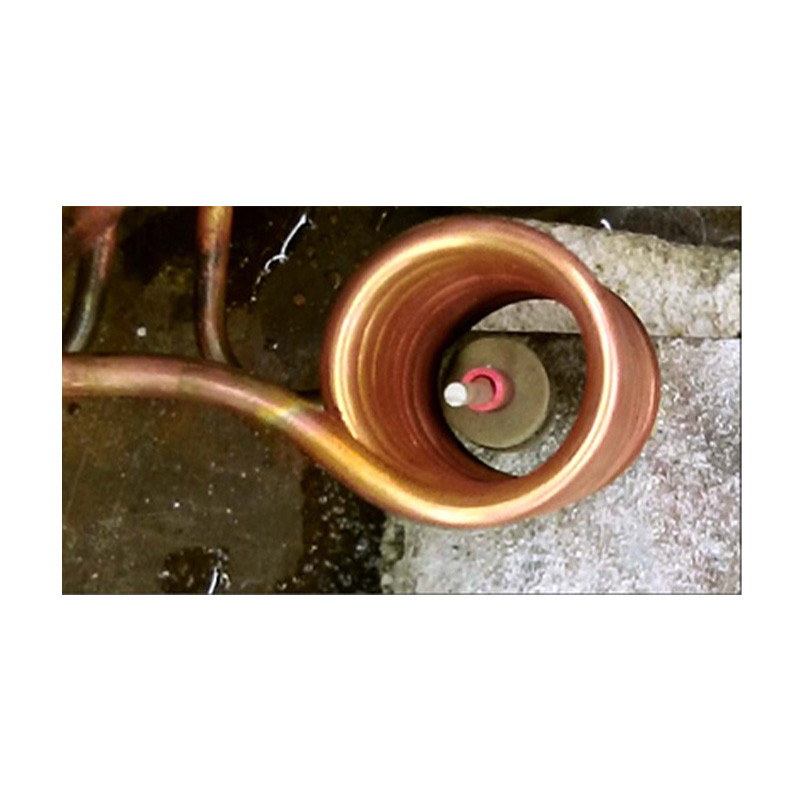

| Objective | To heat a variety of copper tubes for annealing applications; the end products are formed tubes and pipes for various industrial uses |

|---|---|

| Material | Customer supplied copper tubes (height up to 5.5”/ 140 mm and a diameter up to 0.7”/ 17.8 mm) |

| Temperature | 649°C |

| Frequency | 24kHz |

| Equipment |

|

| Process | Initial testing was conducted to optimize the power delivered to the tubes. An EKOHEAT 35 kW/30 kHz induction power supply was used and the power requirements for actual production were calculated based on testing. With a 100 kW power supply, copper tubes – up to the largest diameter required – can be heated to temperature within five seconds. A prototype coil was used during testing. |

| Results |

|

Вы заинтересованы в этом продукте? Вам нужна дополнительная информация или индивидуальные расценки?

Вы должны быть зарегистрированы

| Objective | To heat a variety of copper tubes for annealing applications; the end products are formed tubes and pipes for various industrial uses |

|---|---|

| Material | Customer supplied copper tubes (height up to 5.5”/ 140 mm and a diameter up to 0.7”/ 17.8 mm) |

| Temperature | 649°C |

| Frequency | 24kHz |

| Equipment |

|

| Process | Initial testing was conducted to optimize the power delivered to the tubes. An EKOHEAT 35 kW/30 kHz induction power supply was used and the power requirements for actual production were calculated based on testing. With a 100 kW power supply, copper tubes – up to the largest diameter required – can be heated to temperature within five seconds. A prototype coil was used during testing. |

| Results |

|

Не удаётся отправить вашу оценку отзыва

Пожаловаться на комментарий

Жалоба отправлена

Не удаётся отправить вашу жалобу

Оставьте свой отзыв

Отзыв отправлен

Не удаётся отправить отзыв