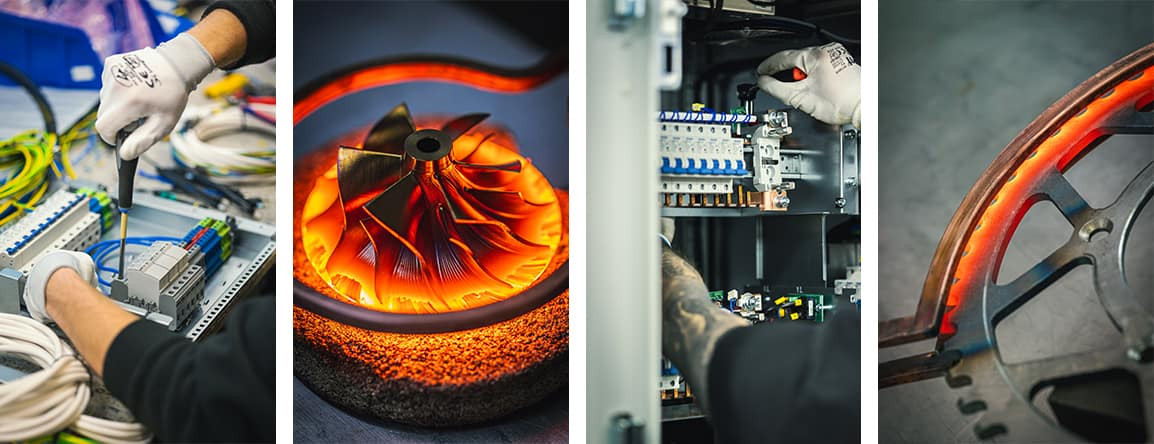

Articolul prezintă drumul de la bazele electronicii până la construirea unor dispozitive mai avansate, evidențiind rolul kiturilor educaționale, al componentelor electronice și al modulelor de putere. Explică modul în care kiturile DIY dezvoltă abilități practice și cum sursele de alimentare, controlerele și elementele de putere adecvat selectate permit realizarea atât a proiectelor hobby, cât și a soluțiilor apropiate de electronica industrială.

Componente pentru electronică de putere, automatizări, electronice, electrice.

Categorii de produse

Vizualizați toate categoriileArticole

-

Iluminat industrial LED vs tradițional – diferențe, beneficii și provocări pentru halele de producție moderneRead more

Articolul prezintă principalele diferențe dintre iluminatul industrial LED și sursele tradiționale de lumină, cum ar fi lămpile cu sodiu sau mercur. Sunt analizate parametrii esențiali care influențează activitatea în halele de producție – eficiența energetică, durata de viață, calitatea luminii, costurile de operare și aspectele ecologice. Se subliniază rolul tot mai important al tehnologiei LED în modernizarea obiectivelor industriale, beneficiile utilizării sale și situațiile în care lămpile tradiționale pot fi încă folosite. Articolul arată de ce LED-urile devin standardul în fabricile și depozitele moderne.

-

Transformarea industrială și energetică – cum energia electronică impulsionează o nouă eră tehnologicăRead more

Acest articol arată cum energia electronică a devenit un factor cheie al transformării moderne a energiei și industriei. Descrie rolul său în integrarea surselor regenerabile, stocarea și conversia energiei, stabilizarea rețelei și automatizarea proceselor industriale. Textul prezintă atât aplicațiile actuale ale tehnologiilor de energie electronică, cât și perspectivele lor de dezvoltare, subliniind importanța pentru dezvoltarea durabilă, digitalizarea infrastructurii și implementarea Industriei 4.0.