Category

Фотографии предназначены только для информационных целей. Посмотреть спецификацию продукта

please use latin characters

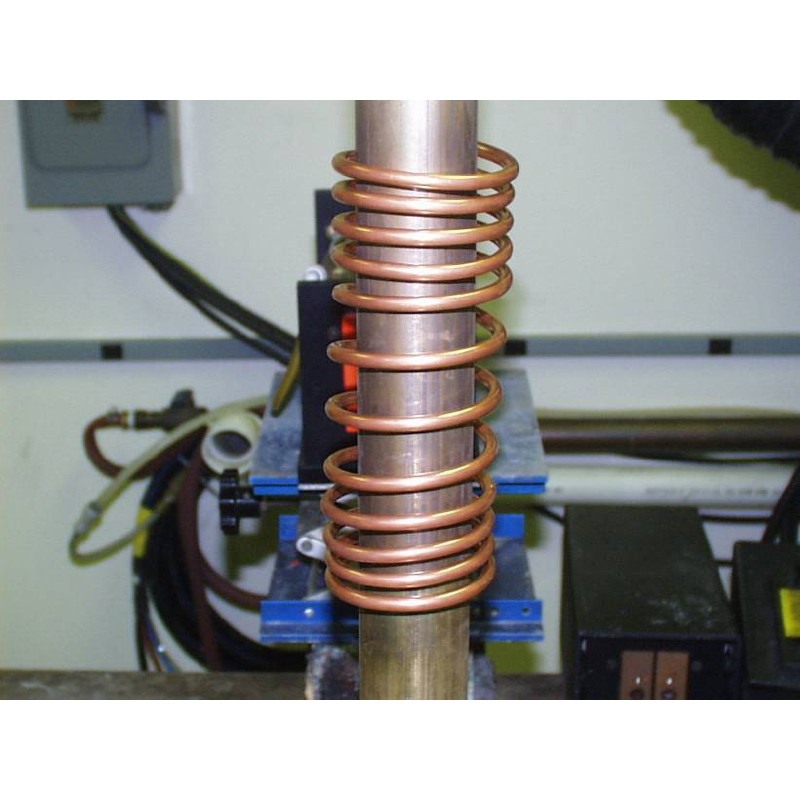

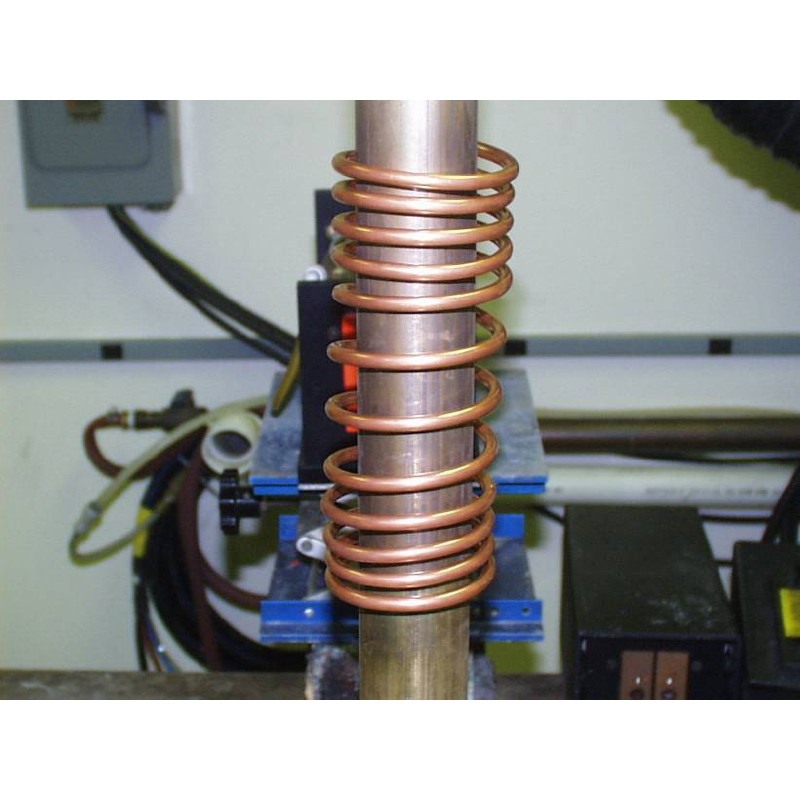

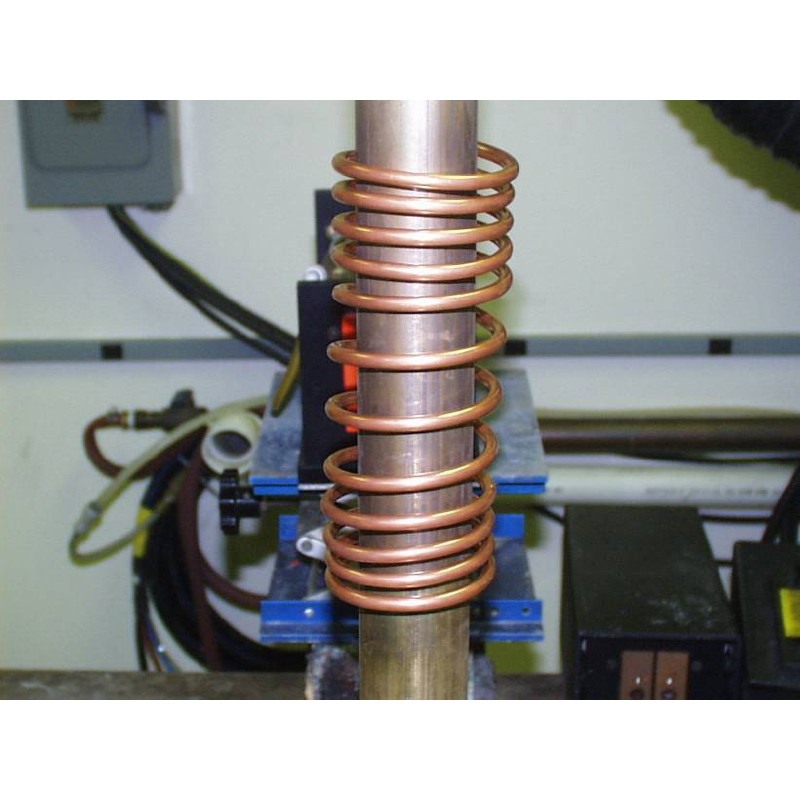

Objective: Annealing brass and bronze tubing for bending in a mandrel bender to form handrails.

Frequency: 228 kHz

Temperature: 1000 °F (538 °C)

A twelve turn helical coil is used to heat an 8” (20.3cm) area 3” (7.6cm) above the end of the tube. Each of the four tubes require a different heat cycle and time to reach the required temperature. Please see the chart below for each tube.

| 1.5" | 1.5" | 2" | 2" | |

| Brass | Bronze | Brass | Bronze | |

| Heat Cycle Time [s] | 80 | 100 | 100 | 120 |

| Power [kW] | 4 | 4.15 | 3.1 | 3.4 |

| Current [A] | 248 | 255 | 200 | 212 |

| Frequency [kHz] | 197 | 197 | 228 | 228 |

Вы заинтересованы в этом продукте? Вам нужна дополнительная информация или индивидуальные расценки?

Вы должны быть зарегистрированы

Objective: Annealing brass and bronze tubing for bending in a mandrel bender to form handrails.

Frequency: 228 kHz

Temperature: 1000 °F (538 °C)

A twelve turn helical coil is used to heat an 8” (20.3cm) area 3” (7.6cm) above the end of the tube. Each of the four tubes require a different heat cycle and time to reach the required temperature. Please see the chart below for each tube.

| 1.5" | 1.5" | 2" | 2" | |

| Brass | Bronze | Brass | Bronze | |

| Heat Cycle Time [s] | 80 | 100 | 100 | 120 |

| Power [kW] | 4 | 4.15 | 3.1 | 3.4 |

| Current [A] | 248 | 255 | 200 | 212 |

| Frequency [kHz] | 197 | 197 | 228 | 228 |

Не удаётся отправить вашу оценку отзыва

Пожаловаться на комментарий

Жалоба отправлена

Не удаётся отправить вашу жалобу

Оставьте свой отзыв

Отзыв отправлен

Не удаётся отправить отзыв