Морате бити пријављени да

Category

Фотографије су само у информативне сврхе. Погледајте спецификацију производа

please use latin characters

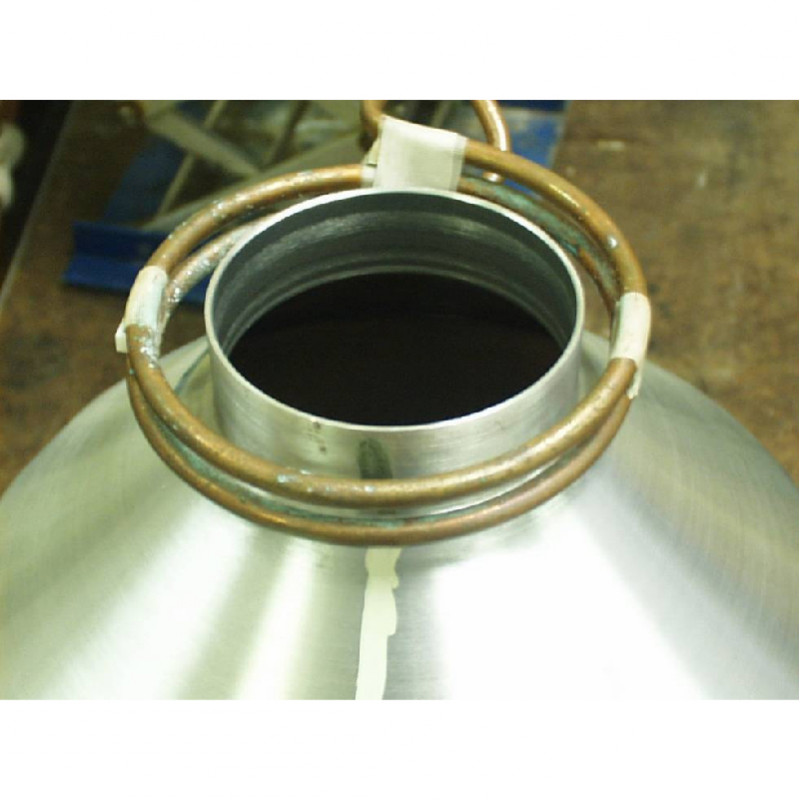

Objective: Annealing a 1” lip on aluminum cryogenic dewar* that has been work hardened during the process of spin forming.

Frequency: 303 kHz

Material: Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thick.

Temperature: 800 °F (427 °C)

A two turn helical coil is used to heat the lip on the cryogenic dewar. The dewar is placed in the coil and power is applied for 2 minutes to anneal the required 1” heat zone.

Да ли вас занима овај производ? Да ли су вам потребне додатне информације или појединачне цене?

морате бити пријављени

Objective: Annealing a 1” lip on aluminum cryogenic dewar* that has been work hardened during the process of spin forming.

Frequency: 303 kHz

Material: Aluminum dewar, lip has a 3.24” (82.3mm) ID and is 0.05” (1.3mm) thick.

Temperature: 800 °F (427 °C)

A two turn helical coil is used to heat the lip on the cryogenic dewar. The dewar is placed in the coil and power is applied for 2 minutes to anneal the required 1” heat zone.

Vaša zahvalnost na komentar ne može biti registrovana

Prijavite nepristojan komentar

Prija nepristojnog komentara registrovana

Vaša prijava nepristojnog komentara ne može biti registrovana

Write your review

Komentar poslat

Vaš komentar ne može biti registrovan