Musisz być zalogowany/a

Kategória

A fényképek csak tájékoztató jellegűek. Lásd a termék specifikációit

Kérjük, használjon latin karaktereket

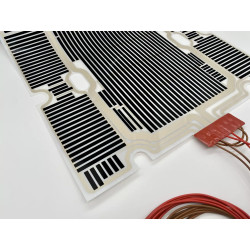

Alper polyester heaters are manufactured using the screen printing method. This production technique allows for a minimal heating element thickness (min. 0.2mm). High quality and precision are the hallmarks of Alper foil heaters.

This fully customizable product range adapts to any desired current and power. Flexible, printed heaters, suitable for a wide range of applications, are used in the tightest spaces where heat is required. Thanks to the thin and flat design of Alper foil heaters, heat is directed only where it is needed, without wasting energy.

The surface in direct contact with the resistance absorbs the radiant heat evenly. Applications include various industries, such as aerospace, marine, small household appliances, and construction. In the lithium battery pack industry, Alper heating elements provide anti-freeze protection and help maintain performance even at low temperatures. Innovation and Production of Flat Heaters Alper's flat and flexible heaters are designed to provide a reliable and durable solution. Alper has modern machinery and uses high-quality ink and material blends. A thin, transparent PET film forms the basis of silver printed paths designed to carry electrical current; a thin layer of carbon ink is deposited on top. Carbon's distinctive properties make it an ideal thermal conductor.

The constant search for new ink formulations with different ohmic values has allowed Alper to make its production capabilities extremely flexible and develop new products according to customer specifications, with the ability to make small changes in required power (+/- 20%) during production, slightly altering the mix proportions without having to redesign the flexible resistance.

Érdekel ez a termék? További információra vagy egyedi árajánlatra van szüksége?

Musisz być zalogowany/a

Alper polyester heaters are manufactured using the screen printing method. This production technique allows for a minimal heating element thickness (min. 0.2mm). High quality and precision are the hallmarks of Alper foil heaters.

This fully customizable product range adapts to any desired current and power. Flexible, printed heaters, suitable for a wide range of applications, are used in the tightest spaces where heat is required. Thanks to the thin and flat design of Alper foil heaters, heat is directed only where it is needed, without wasting energy.

The surface in direct contact with the resistance absorbs the radiant heat evenly. Applications include various industries, such as aerospace, marine, small household appliances, and construction. In the lithium battery pack industry, Alper heating elements provide anti-freeze protection and help maintain performance even at low temperatures. Innovation and Production of Flat Heaters Alper's flat and flexible heaters are designed to provide a reliable and durable solution. Alper has modern machinery and uses high-quality ink and material blends. A thin, transparent PET film forms the basis of silver printed paths designed to carry electrical current; a thin layer of carbon ink is deposited on top. Carbon's distinctive properties make it an ideal thermal conductor.

The constant search for new ink formulations with different ohmic values has allowed Alper to make its production capabilities extremely flexible and develop new products according to customer specifications, with the ability to make small changes in required power (+/- 20%) during production, slightly altering the mix proportions without having to redesign the flexible resistance.

A megfogalmazott véleményedet nem lehet elküldeni

Hozzászólás jelentése

Jelentés elküldve

Jelentésed beküldése nem lehetséges

Írd meg véleményedet

Vélemény elküldve

Véleményed nem lehet elküldeni