Category

Photos are for informational purposes only. View product specification

please use latin characters

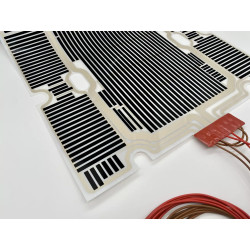

Alper polyester heaters are manufactured using the screen printing method. This production technique allows for minimizing the thickness of the heating element (min. 0.2mm). High quality and precision are the distinguishing features of Alper foil heaters.

This fully customizable product range adapts to any desired current intensity and power. Flexible printed heaters, suitable for many applications, are used in the tightest spaces where heat is required. Thanks to the thin and flat form of Alper foil heaters, heat is directed only where needed, without wasting energy.

The surface in direct contact with the resistance absorbs uniformly radiating heat. There are various areas of application, such as the aerospace, marine, small household appliances (HAs) and construction industries. In the lithium battery pack industry, Alper heating elements serve an anti-freezing function and help maintain efficiency even at low temperatures.

Alper’s flat and flexible heaters are created to provide a reliable and durable solution. Alper has modern machinery, uses high-quality ink mixtures and materials. A thin, transparent PET film forms the base for the printed silver tracks designed to transport electric current; a thin layer of carbon ink is deposited on top. The distinguishing properties of carbon make it an ideal heating conductor.

The continuous search for new ink formulas with different ohmic values allowed Alper to make production capabilities extremely flexible and to develop new products according to customer specifications, with the possibility of introducing small changes in the required power (+/- 20%) during production, slightly changing the mixture proportions without the need to redesign the flexible resistance.

Ready to upgrade your cooking experience with the latest in kitchen tech?

ALPER flexible heating elements heat specific areas, preventing the condensation of cooking vapors on the kitchen cooker hoods’ surface. ALPER heating elements are easy to install, they help to protect appliances and reduce maintenance.

Alper defogging heaters are designed to prevent condensation from forming on the cooker hood's surface, especially for kitchen cooker hoods above induction hobs. The phenomenon of dripping vapors on the cooker hob may cause appliance damage. Alper heaters prevent these bad inconveniences.

Are you interested in this product? Do you need additional information or individual pricing?

Alper polyester heaters are manufactured using the screen printing method. This production technique allows for minimizing the thickness of the heating element (min. 0.2mm). High quality and precision are the distinguishing features of Alper foil heaters.

This fully customizable product range adapts to any desired current intensity and power. Flexible printed heaters, suitable for many applications, are used in the tightest spaces where heat is required. Thanks to the thin and flat form of Alper foil heaters, heat is directed only where needed, without wasting energy.

The surface in direct contact with the resistance absorbs uniformly radiating heat. There are various areas of application, such as the aerospace, marine, small household appliances (HAs) and construction industries. In the lithium battery pack industry, Alper heating elements serve an anti-freezing function and help maintain efficiency even at low temperatures.

Alper’s flat and flexible heaters are created to provide a reliable and durable solution. Alper has modern machinery, uses high-quality ink mixtures and materials. A thin, transparent PET film forms the base for the printed silver tracks designed to transport electric current; a thin layer of carbon ink is deposited on top. The distinguishing properties of carbon make it an ideal heating conductor.

The continuous search for new ink formulas with different ohmic values allowed Alper to make production capabilities extremely flexible and to develop new products according to customer specifications, with the possibility of introducing small changes in the required power (+/- 20%) during production, slightly changing the mixture proportions without the need to redesign the flexible resistance.

Ready to upgrade your cooking experience with the latest in kitchen tech?

ALPER flexible heating elements heat specific areas, preventing the condensation of cooking vapors on the kitchen cooker hoods’ surface. ALPER heating elements are easy to install, they help to protect appliances and reduce maintenance.

Alper defogging heaters are designed to prevent condensation from forming on the cooker hood's surface, especially for kitchen cooker hoods above induction hobs. The phenomenon of dripping vapors on the cooker hob may cause appliance damage. Alper heaters prevent these bad inconveniences.

Printed Electronics

Printed Electronics

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent