Category

Photos are for informational purposes only. View product specification

please use latin characters

Construction:

Connections consists of tapes put out together. Tips are made according to welding process with press.

The same process allows to strengthen material, which is used for tips. There is no contact resistance between tapes.

Ranges:

-Standard width:

20mm - 35mm - 48mm - 58mm - 80mm - 100mm - 120mm - 150mm - 200mm (other dimensions for request),

-tape thickness: 0,1 mm, 0,2mm, 0,3mm,

-thickness of parallel connected tapes.

Options

-silvered external tapes which provides tips protection, without any chemical processing.

-Tips surface processing: tinning, silvering, galvanizing, gilding.

-Specific shapes for client request.

-mechanical enforcement of flexible connections

-welding MIG,

-tin welding,

-riveting,

-rolling.

Application range:

-High power supply systems, bakes, electrolysis.

-Medium voltage area

-transformers

Advantages:

The press welding process allows to protect physical properties( electrical, mechanical and thermal)

Welding with press:

-shaping,

-chemical process of tip surface: silvered or tinned according to DALIC process.

BT press welding:

-Additional silvered tapes without any chemical scraps during exploitation.

Technical properties:

-copper classification: ISO 1337,

-description: Cu-OF (non oxygen),

-copper content: 99,9%,

-resistivity: 1,7241µΩ/cm.

| Copper properties: | ||

| marking 0 | marking H 14 | |

| -resistance for stretching: | 200Mpa | 300Mpa, |

| -elongation: | 30% | 6%, |

| -thickness: | < 55 HV | > 100 HV. |

| Description | ||

| - CS: | flexible connection | |

| - FD: | in tapes | |

| - section: | in mm2, | |

| - CN: | material - red copper, | |

| - 100 x 10 x 400: | width x thickness x length. | |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

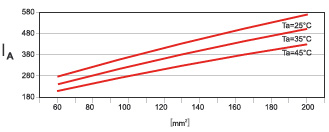

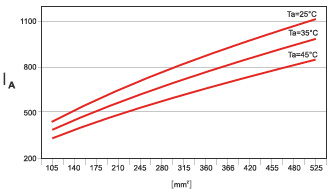

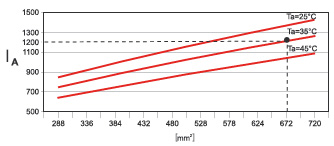

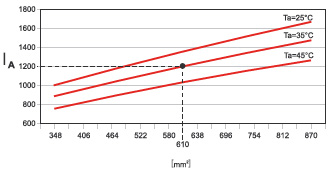

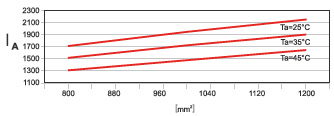

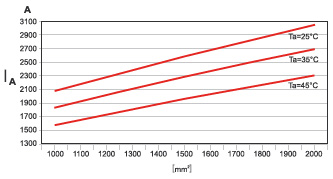

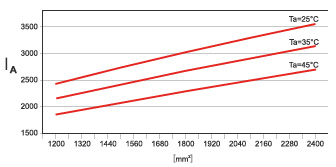

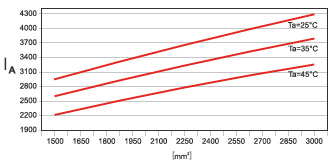

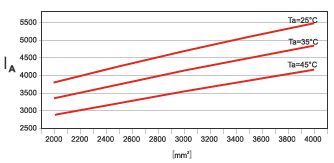

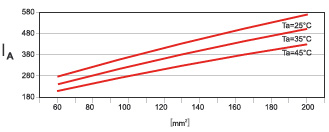

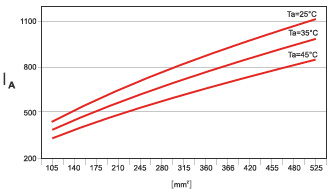

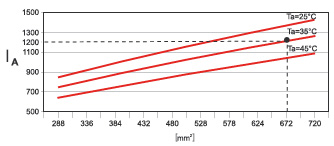

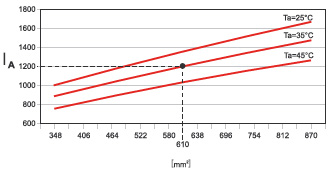

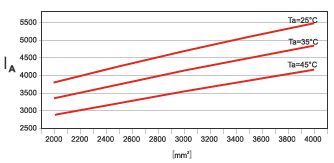

Connections are assembled vertically, when they are used in parallel. Minimum distance between 2 connections is one connection size.

In case of several connections in the same phase, it is necessary to calculate total section with a coefficient.W przypadku kilku połączeń włączonych równolegle do tej samej fazy, konieczne jest wyliczenie całkowitego przekroju przy pomocy odpowiedniego współczynnika:

| Quantity of parallel connections | Coefficient |

|---|---|

| 2 | 1,8 |

| 3 | 2,5 |

| 4 | 3,2 |

| 5 | 3,9 |

| 6 | 4,4 |

| 8 | 5,5 |

| 10 | 6,5 |

Calculated current= Current / coefficient.

|

|

|

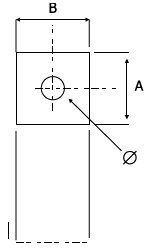

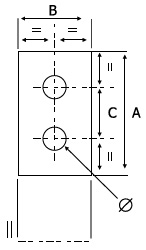

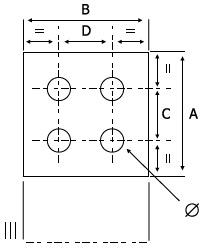

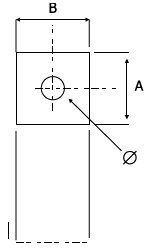

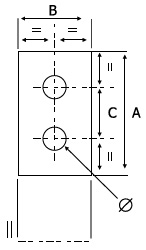

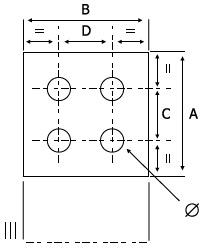

Three standards: type I, II, III.

-holes position A, B, C i D,

-diameter: Ø

-other tips for request

Are you interested in this product? Do you need additional information or individual pricing?

Construction:

Connections consists of tapes put out together. Tips are made according to welding process with press.

The same process allows to strengthen material, which is used for tips. There is no contact resistance between tapes.

Ranges:

-Standard width:

20mm - 35mm - 48mm - 58mm - 80mm - 100mm - 120mm - 150mm - 200mm (other dimensions for request),

-tape thickness: 0,1 mm, 0,2mm, 0,3mm,

-thickness of parallel connected tapes.

Options

-silvered external tapes which provides tips protection, without any chemical processing.

-Tips surface processing: tinning, silvering, galvanizing, gilding.

-Specific shapes for client request.

-mechanical enforcement of flexible connections

-welding MIG,

-tin welding,

-riveting,

-rolling.

Application range:

-High power supply systems, bakes, electrolysis.

-Medium voltage area

-transformers

Advantages:

The press welding process allows to protect physical properties( electrical, mechanical and thermal)

Welding with press:

-shaping,

-chemical process of tip surface: silvered or tinned according to DALIC process.

BT press welding:

-Additional silvered tapes without any chemical scraps during exploitation.

Technical properties:

-copper classification: ISO 1337,

-description: Cu-OF (non oxygen),

-copper content: 99,9%,

-resistivity: 1,7241µΩ/cm.

| Copper properties: | ||

| marking 0 | marking H 14 | |

| -resistance for stretching: | 200Mpa | 300Mpa, |

| -elongation: | 30% | 6%, |

| -thickness: | < 55 HV | > 100 HV. |

| Description | ||

| - CS: | flexible connection | |

| - FD: | in tapes | |

| - section: | in mm2, | |

| - CN: | material - red copper, | |

| - 100 x 10 x 400: | width x thickness x length. | |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Connections are assembled vertically, when they are used in parallel. Minimum distance between 2 connections is one connection size.

In case of several connections in the same phase, it is necessary to calculate total section with a coefficient.W przypadku kilku połączeń włączonych równolegle do tej samej fazy, konieczne jest wyliczenie całkowitego przekroju przy pomocy odpowiedniego współczynnika:

| Quantity of parallel connections | Coefficient |

|---|---|

| 2 | 1,8 |

| 3 | 2,5 |

| 4 | 3,2 |

| 5 | 3,9 |

| 6 | 4,4 |

| 8 | 5,5 |

| 10 | 6,5 |

Calculated current= Current / coefficient.

|

|

|

Three standards: type I, II, III.

-holes position A, B, C i D,

-diameter: Ø

-other tips for request

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent