Category

Photos are for informational purposes only. View product specification

please use latin characters

The MELA®-sensing modules are sub-assemblies which are used to measure relative humidity, relative humidity uad temperature, and temperature in air and other nonaggressive gases.

The MELA®-sensing modules are available as printed circuit board installation modules (OEM modules). With the wide range of types, these modules can be used for a wide range of applications.

User instructions

Install the MELA®-sensing modules at a place in the room or equipment where characteristic levels of humidity occur.

The proximity of heat sources, installation on external walls or installation in a splash area are to be avoided; ensure good ventilation of the sensor element.

The specified minimum air speeds and the operating voltage-adapted current at current-output (diagram) should be

complied with. Deviations may lead to additional corrupted measurement readings because the sensor self-heats.

Dew formation and splashes do not damage the sensing modules,although corrupted measurement readings are recorded until all the moisture on and directly around the sensor element has dried up.

Dust does not cause any harm , however, it does affect dynamic performance.

If there is an excessive build-up of dust then you can unscrew the protective cap ZE16 resp. ZE04 on the series .../9 and carefully rinse the sensor head with distilled water. The element filter made of PTFE is not exchangeable.

On the series .../5 and .../6 the stainless steel sinter filter ZE21 and ZE13 can also be unscrewed and rinsed out with distilled water. Loose dirt can also be removed from the measuring element by blowing it off or by rinsing it carefully with distilled water. In order to avoid corrupted measurement readings, only screw the above mentioned sintered inox fi lter back on when they are completely dry. Do not touch the highly sensitive sensor

element.

Please consult the application instructions for the sensing elements (product info sheet no. A 1) or check with the manufacturer for further information which you need to bear in mind when using humidity sensors with capacitive sensing elements. In order to check functioning in the place of installation, we recommend that you use the MELA®-ZE31/1-type humidity standard with a ZE 33-type auxiliary adapter.

Technical Data:

| Humidity | ||

| • measuring range | 0...100%rh | |

| • accuracy (MR 5...95%rh @10...40°C | ±2% rh | |

| • Additional error(<10°C, >40 °C | <0,1%/K | |

| • Reaction time | ||

| (T90 for 1m/s) | 10s | |

| (T 90 przy 1m/s)10s ( Series xVM) | 1min | |

| Temperature | ||

| • measuring element ( (DIN IEC 751) | Pt100 class B | |

| • measuring range temperature | -30...80°C | |

| class 1/3 DIN on reques | ||

| • accuracy | ||

| 0...1V (-17...80 °C) | ±0,2 K | |

| 0...10V (-19...80 °C) | ±0,2 K | |

| 4...20mA | ±0,3K | |

| • Additional error (<10°C, >40°C | ±0,007K/ K | |

| •Reaction time (T 90) | 10s | |

| xVM dla 1m/s | 1 min | |

| Other data | ||

| • ambient temperature | -40...80°C | |

| • power consumption | ||

| 0...10V, 2x0...1V | <5mA | |

| 0...1V | <1mA | |

| • minimum air speed (across the sensor) | ||

| output 2x4...20mA | 1,5m/s | |

| 4...20mA, 2x0...10V | 1m/s | |

| 0...10V, 2x0...10V | 0,5m/s | |

| • load resistance (voltage output 0...10V/0...1V) | 310kW/32kW | |

| • load (current output) | zobacz wykres | |

| • operating voltage | ||

| current output | 12...30V DC | |

| voltage output 0...10V | 15...30V DC | |

| voltage output 0...1V | 6...30V DC | |

| • self-heating Pt100 (v=2 m/s in air) | 0,1K | |

| Type versions measured variable |

output | OM series printed circuit |

GM series alu tube with thread |

VM series stainless steel tube with thread |

|---|---|---|---|---|

| F relative humidity |

4...20 mA | FOM 3/5 | FGM 3/5 | FVM 3/5 |

| 0...10 V | FOM 2/5 | FGM 2/5 | FVM 2/5 | |

| 0...1 V | FOM 1/5 | FGM 1/5 | FVM 1/5*) | |

| C rel.humidity + temp. passive |

4...20 mA, Pt100 | COM 3/5 | CGM 3/5 | CVM 3/5 |

| 0...10 V, Pt100 | COM 2/5 | CGM 2/5 | CVM 2/5 | |

| 0...1 V, Pt100 | COM 1/5 | CGM 1/5 | CVM 1/5 | |

| K rel.humidity + temp. active |

2 x 4...20 mA | KOM 3/5 | KGM 3/5 | KVM 3/5 |

| 2 x 0...10 V | KOM 2/5 | KGM 2/5 | KVM 2/5 | |

| 2 x 0...1 V | KOM 1/5 | KGM 1/5 | KVM 1/5 | |

| T temperature |

4...20mA | TOM 3/5 | TGM 3/5 | TVM 3/5 |

| 0...10V | TOM 2/5 | TGM 2/5 | TVM 2/5 | |

| 0...1V | TOM 1/5 | TGM 1/5 | TVM 1/5 | |

| weight | 6g | 23g | 27g | |

|

Load at current output

|

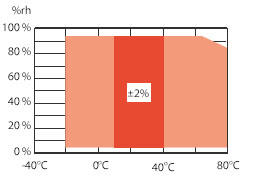

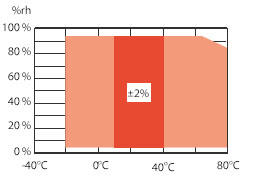

Humidity working range

|

|

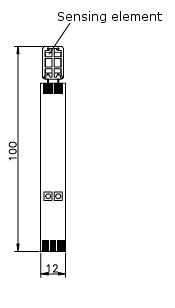

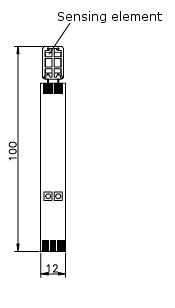

Series OM

|

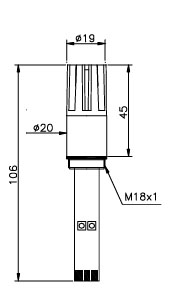

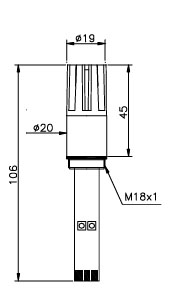

Series GM

|

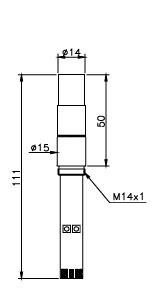

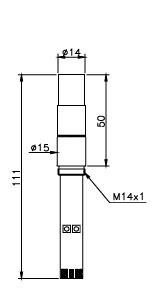

Series VM

|

Are you interested in this product? Do you need additional information or individual pricing?

The MELA®-sensing modules are sub-assemblies which are used to measure relative humidity, relative humidity uad temperature, and temperature in air and other nonaggressive gases.

The MELA®-sensing modules are available as printed circuit board installation modules (OEM modules). With the wide range of types, these modules can be used for a wide range of applications.

User instructions

Install the MELA®-sensing modules at a place in the room or equipment where characteristic levels of humidity occur.

The proximity of heat sources, installation on external walls or installation in a splash area are to be avoided; ensure good ventilation of the sensor element.

The specified minimum air speeds and the operating voltage-adapted current at current-output (diagram) should be

complied with. Deviations may lead to additional corrupted measurement readings because the sensor self-heats.

Dew formation and splashes do not damage the sensing modules,although corrupted measurement readings are recorded until all the moisture on and directly around the sensor element has dried up.

Dust does not cause any harm , however, it does affect dynamic performance.

If there is an excessive build-up of dust then you can unscrew the protective cap ZE16 resp. ZE04 on the series .../9 and carefully rinse the sensor head with distilled water. The element filter made of PTFE is not exchangeable.

On the series .../5 and .../6 the stainless steel sinter filter ZE21 and ZE13 can also be unscrewed and rinsed out with distilled water. Loose dirt can also be removed from the measuring element by blowing it off or by rinsing it carefully with distilled water. In order to avoid corrupted measurement readings, only screw the above mentioned sintered inox fi lter back on when they are completely dry. Do not touch the highly sensitive sensor

element.

Please consult the application instructions for the sensing elements (product info sheet no. A 1) or check with the manufacturer for further information which you need to bear in mind when using humidity sensors with capacitive sensing elements. In order to check functioning in the place of installation, we recommend that you use the MELA®-ZE31/1-type humidity standard with a ZE 33-type auxiliary adapter.

Technical Data:

| Humidity | ||

| • measuring range | 0...100%rh | |

| • accuracy (MR 5...95%rh @10...40°C | ±2% rh | |

| • Additional error(<10°C, >40 °C | <0,1%/K | |

| • Reaction time | ||

| (T90 for 1m/s) | 10s | |

| (T 90 przy 1m/s)10s ( Series xVM) | 1min | |

| Temperature | ||

| • measuring element ( (DIN IEC 751) | Pt100 class B | |

| • measuring range temperature | -30...80°C | |

| class 1/3 DIN on reques | ||

| • accuracy | ||

| 0...1V (-17...80 °C) | ±0,2 K | |

| 0...10V (-19...80 °C) | ±0,2 K | |

| 4...20mA | ±0,3K | |

| • Additional error (<10°C, >40°C | ±0,007K/ K | |

| •Reaction time (T 90) | 10s | |

| xVM dla 1m/s | 1 min | |

| Other data | ||

| • ambient temperature | -40...80°C | |

| • power consumption | ||

| 0...10V, 2x0...1V | <5mA | |

| 0...1V | <1mA | |

| • minimum air speed (across the sensor) | ||

| output 2x4...20mA | 1,5m/s | |

| 4...20mA, 2x0...10V | 1m/s | |

| 0...10V, 2x0...10V | 0,5m/s | |

| • load resistance (voltage output 0...10V/0...1V) | 310kW/32kW | |

| • load (current output) | zobacz wykres | |

| • operating voltage | ||

| current output | 12...30V DC | |

| voltage output 0...10V | 15...30V DC | |

| voltage output 0...1V | 6...30V DC | |

| • self-heating Pt100 (v=2 m/s in air) | 0,1K | |

| Type versions measured variable |

output | OM series printed circuit |

GM series alu tube with thread |

VM series stainless steel tube with thread |

|---|---|---|---|---|

| F relative humidity |

4...20 mA | FOM 3/5 | FGM 3/5 | FVM 3/5 |

| 0...10 V | FOM 2/5 | FGM 2/5 | FVM 2/5 | |

| 0...1 V | FOM 1/5 | FGM 1/5 | FVM 1/5*) | |

| C rel.humidity + temp. passive |

4...20 mA, Pt100 | COM 3/5 | CGM 3/5 | CVM 3/5 |

| 0...10 V, Pt100 | COM 2/5 | CGM 2/5 | CVM 2/5 | |

| 0...1 V, Pt100 | COM 1/5 | CGM 1/5 | CVM 1/5 | |

| K rel.humidity + temp. active |

2 x 4...20 mA | KOM 3/5 | KGM 3/5 | KVM 3/5 |

| 2 x 0...10 V | KOM 2/5 | KGM 2/5 | KVM 2/5 | |

| 2 x 0...1 V | KOM 1/5 | KGM 1/5 | KVM 1/5 | |

| T temperature |

4...20mA | TOM 3/5 | TGM 3/5 | TVM 3/5 |

| 0...10V | TOM 2/5 | TGM 2/5 | TVM 2/5 | |

| 0...1V | TOM 1/5 | TGM 1/5 | TVM 1/5 | |

| weight | 6g | 23g | 27g | |

|

Load at current output

|

Humidity working range

|

|

Series OM

|

Series GM

|

Series VM

|

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent