Category

Photos are for informational purposes only. View product specification

please use latin characters

Construction:

Elastic buses are made from copper tapes, protected by PCV(9mm do 50mm) which provides electric insulation even when the elastic connection is twisted or used in different environments(humidity, high temperature, aggressive surrounding)

Range:

-Standard length: 2000mm and 3000mm (other dimensions),

-tape thickness: 0,5 mm - 1mm,

-tape quantity: 2 - 12.

Options:

-Tinned copper or aluminium(or request)

-elastic connections

-non halogen,

-high temperature insulation: +125°C.

Advantages:

This is the only electrical connection system, which combine properties of connection shaping and conductor insulation. Connection work out costs are smaller because of material usage, which price is comparable to cables, connectors and casings.

Comparison -elastic bus to stiff bars:

-better electrical properties and bigger safety.

-Space profit because of closed assembly of elastic connections.

-Easy to shape because of flexibility.

Comparison - elastic buses to cables

-Time saving because of easier connection - no need to make additional connectors.

-No contact resistance, which occurs between cable and connector.

-Space profit.

-No casings or glands.

| Technical properties PVC: | ||

| -Density | 1,31 | NFT51-063, |

| -Shore hardness: | 85 A | NFT 51-109, |

| -Maximum resistance for stretching | 19,6 Mpa | NFT 51-034, |

| -maximum elongation | 365% | NFT 51-034, |

| -heat conductance: | 3 do 4 10-4cal/s/cm/°C, | |

| -dielectric withstand | 20 kV/mm, | |

| -fire demands | class FV 0 | UL 94v0, |

| -utilisation: | yes | |

| Tapes: | ||

| Copper classification: | according to NF A 51-050, | |

| -marking: | Cu-ETP marking O, | |

| -copper content: | 99,9%, | |

| -resistivity: | 1,7241 µΩ/cm. | |

| Copper properties | according to NF A 51-100, | |

| -resistance for stretching | 200 Mpa min, | |

| -elongation: | 30 % min, | |

| -thickness: | < 55 HV. | |

| Elastic busses : | ||

| -maximum voltage: | 1000V, | |

| -operation time: | -40°C do +105°C, | |

| -PVC thickness: | 2.0 mm, | |

| -dielectric withstand: | average 20kV/mm | according to NFC 32-201-1, |

| -flame resistance | according to NFC 32-070 C2. | |

| Markings | ||

| -ES: | elastic bus | |

| -24: | tape width [mm] | |

| -1: | tape thickness [mm] | |

| -8: | tape quantity |

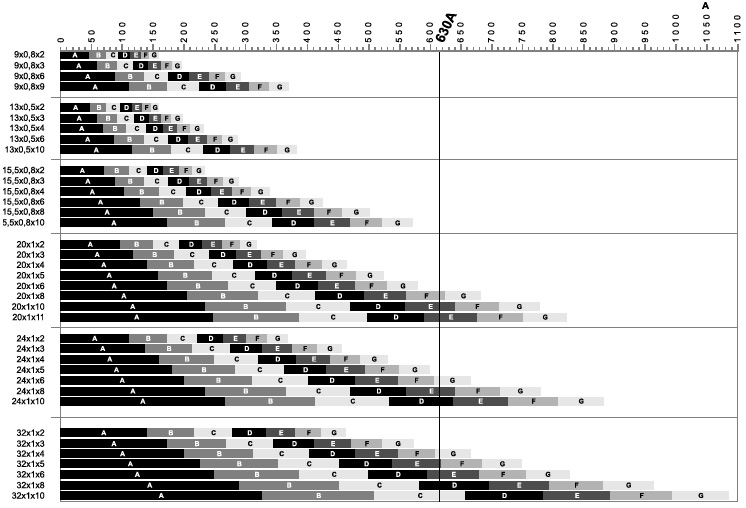

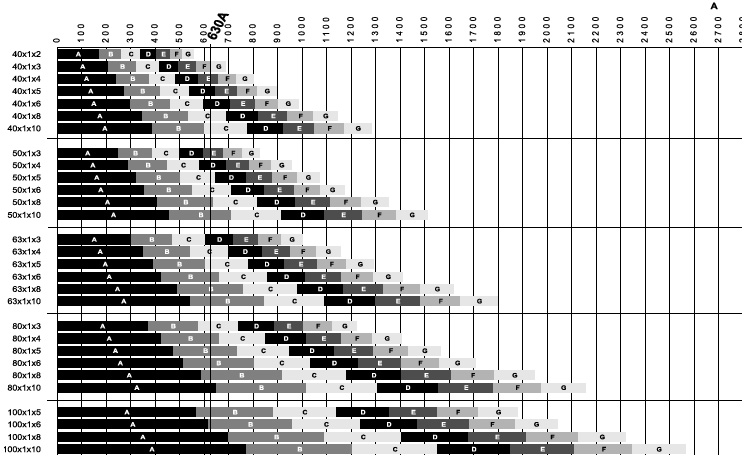

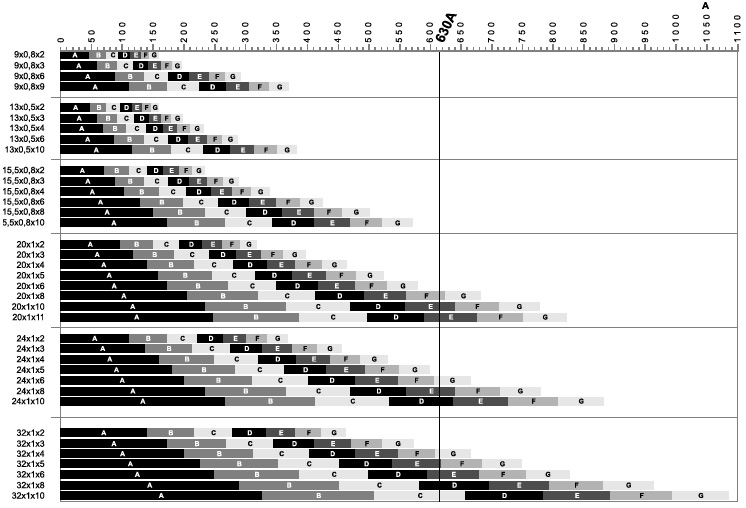

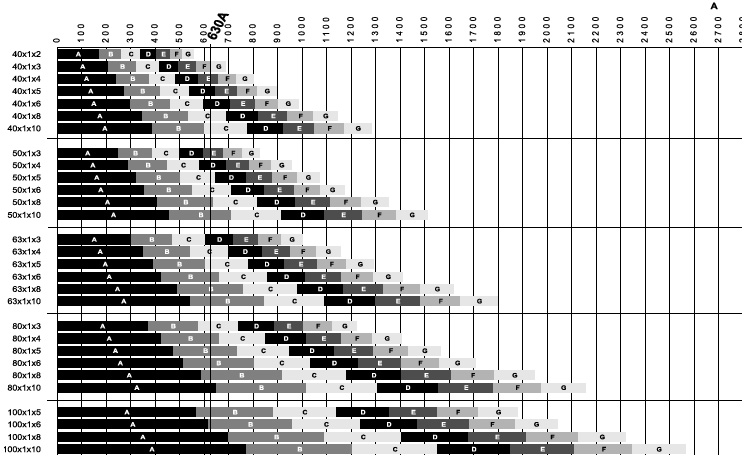

Overheat of flexible elements is shown on a chart and table.

1 - Elastic bus

2 - Tape width (mm)

3 - Tape thickness (mm)

4 - Tape quantity (mm)

| Tape quantity | Dimensions [mm] |

Width x thickness [mm] |

Section [mm2] |

Overheat | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A 10 °C |

B 20 °C |

C 30 °C |

D 40 °C |

E 50 °C |

F 60 °C |

G 70 °C |

||||

| 2 | 9x0,8x2 | 9x0,8 | 14,4 | 47 | 74 | 95 | 114 | 130 | 144 | 157 |

| 3 | 9x0,8x3 | 9x0,8 | 21,6 | 59 | 92 | 119 | 141 | 162 | 180 | 196 |

| 6 | 9x0,8x6 | 9x0,8 | 43,2 | 88 | 137 | 176 | 210 | 240 | 266 | 291 |

| 9 | 9x0,8x9 | 9x0,8 | 64,8 | 112 | 174 | 225 | 268 | 306 | 340 | 371 |

| 2 | 13x0,5x2 | 13x0,5 | 13 | 48 | 75 | 97 | 116 | 132 | 147 | 160 |

| 3 | 13x0,5x3 | 13x0,5 | 19,5 | 60 | 93 | 120 | 143 | 163 | 181 | 198 |

| 4 | 13x0,5x4 | 13x0,5 | 26 | 69 | 108 | 140 | 166 | 190 | 211 | 231 |

| 6 | 13x0,5x6 | 13x0,5 | 39 | 87 | 135 | 174 | 207 | 237 | 263 | 288 |

| 10 | 13x0,5x10 | 13x0,5 | 65 | 115 | 180 | 232 | 276 | 316 | 351 | 383 |

| 2 | 15x0,8x2 | 15,5x0,8 | 24,8 | 70 | 110 | 141 | 168 | 192 | 214 | 234 |

| 3 | 15x0,8x3 | 15,5x0,8 | 37,2 | 87 | 136 | 175 | 209 | 239 | 265 | 290 |

| 4 | 15x0,8x4 | 15,5x0,8 | 49,6 | 102 | 159 | 205 | 244 | 279 | 310 | 339 |

| 6 | 15x0,8x6 | 15,5x0,8 | 74,4 | 128 | 199 | 257 | 306 | 350 | 389 | 424 |

| 8 | 15x0,8x8 | 15,5x0,8 | 99,2 | 151 | 235 | 303 | 361 | 412 | 458 | 501 |

| 10 | 15,5x0,8x10 | 15,5x0,8 | 124 | 172 | 268 | 345 | 411 | 470 | 523 | 571 |

| 2 | 20x1x2 | 20x1 | 40 | 96 | 150 | 193 | 230 | 263 | 292 | 319 |

| 3 | 20x1x3 | 20x1 | 60 | 119 | 186 | 240 | 286 | 326 | 263 | 396 |

| 4 | 20x1x4 | 20x1 | 80 | 139 | 217 | 280 | 334 | 381 | 424 | 463 |

| 5 | 20x1x5 | 20x1 | 100 | 158 | 246 | 317 | 377 | 431 | 479 | 523 |

| 6 | 20x1x6 | 20x1 | 120 | 174 | 272 | 351 | 418 | 477 | 531 | 580 |

| 8 | 20x1x8 | 20x1 | 160 | 205 | 321 | 413 | 492 | 562 | 325 | 683 |

| 10 | 20x1x10 | 20x1 | 200 | 234 | 365 | 470 | 560 | 640 | 711 | 777 |

| 11 | 20x1x11 | 20x1 | 220 | 247 | 386 | 497 | 592 | 676 | 752 | 821 |

| 2 | 24x1x2 | 24x1 | 48 | 111 | 173 | 223 | 265 | 303 | 337 | 368 |

| 3 | 24x1x3 | 24x1 | 72 | 137 | 214 | 276 | 329 | 375 | 417 | 456 |

| 4 | 24x1x4 | 24x1 | 96 | 160 | 250 | 322 | 383 | 438 | 487 | 532 |

| 5 | 24x1x5 | 24x1 | 120 | 181 | 282 | 363 | 433 | 494 | 550 | 600 |

| 6 | 24x1x6 | 24x1 | 144 | 200 | 312 | 402 | 479 | 547 | 608 | 664 |

| 8 | 24x1x8 | 24x1 | 192 | 234 | 366 | 471 | 562 | 641 | 713 | 779 |

| 10 | 24x1x10 | 24x1 | 240 | 266 | 415 | 534 | 637 | 727 | 809 | 883 |

| 2 | 32x1x2 | 32x1 | 64 | 139 | 218 | 280 | 334 | 382 | 424 | 463 |

| 3 | 32x1x3 | 32x1 | 96 | 172 | 269 | 346 | 413 | 471 | 524 | 572 |

| 4 | 32x1x4 | 32x1 | 128 | 200 | 313 | 403 | 480 | 548 | 610 | 666 |

| 5 | 32x1x5 | 32x1 | 160 | 226 | 352 | 453 | 540 | 617 | 686 | 749 |

| 6 | 32x1x6 | 32x1 | 192 | 249 | 388 | 500 | 596 | 680 | 756 | 826 |

| 8 | 32x1x8 | 32x1 | 256 | 290 | 452 | 695 | 695 | 793 | 882 | 963 |

| 10 | 32x1x10 | 32x1 | 320 | 327 | 510 | 657 | 783 | 894 | 995 | 1086 |

| Tape quantity | Dimensions [mm] |

Width x thickness [mm] |

Section [mm2] |

Overheat | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A 10 °C |

B 20 °C |

C 30 °C |

D 40 °C |

E 50 °C |

F 60 °C |

G 70 °C |

||||

| 2 | 40x1x2 | 40x1 | 80 | 167 | 261 | 337 | 401 | 458 | 510 | 556 |

| 3 | 40x1x3 | 40x1 | 120 | 206 | 322 | 415 | 494 | 565 | 628 | 686 |

| 4 | 40x1x4 | 40x1 | 160 | 240 | 374 | 481 | 574 | 655 | 729 | 796 |

| 6 | 40x1x5 | 40x1 | 200 | 269 | 420 | 541 | 644 | 736 | 818 | 894 |

| 6 | 40x1x6 | 40x1 | 240 | 296 | 461 | 594 | 708 | 809 | 900 | 982 |

| 8 | 40x1x8 | 40x1 | 320 | 243 | 535 | 690 | 822 | 939 | 1044 | 1140 |

| 10 | 40x1x10 | 40x1 | 400 | 285 | 601 | 774 | 922 | 1053 | 1171 | 1279 |

| 3 | 50x1x3 | 50x1 | 150 | 248 | 387 | 498 | 594 | 679 | 755 | 824 |

| 4 | 50x1x4 | 50x1 | 200 | 287 | 448 | 577 | 688 | 786 | 874 | 954 |

| 5 | 50x1x5 | 50x1 | 250 | 322 | 502 | 646 | 770 | 880 | 987 | 1068 |

| 6 | 50x1x6 | 50x1 | 300 | 352 | 550 | 709 | 844 | 965 | 1073 | 1171 |

| 8 | 50x1x8 | 50x1 | 400 | 407 | 635 | 818 | 975 | 1114 | 1238 | 1352 |

| 10 | 50x1x10 | 50x1 | 500 | 455 | 709 | 914 | 1089 | 1244 | 1383 | 1510 |

| 3 | 63x1x3 | 63x1 | 189 | 301 | 469 | 604 | 720 | 823 | 915 | 999 |

| 4 | 63x1x4 | 63x1 | 252 | 347 | 542 | 698 | 832 | 950 | 1056 | 1153 |

| 5 | 63x1x5 | 63x1 | 315 | 388 | 605 | 779 | 929 | 1061 | 1179 | 1288 |

| 6 | 63x1x6 | 63x1 | 378 | 424 | 661 | 852 | 1015 | 1159 | 1289 | 1408 |

| 8 | 63x1x8 | 63x1 | 504 | 487 | 759 | 978 | 1166 | 1332 | 1481 | 1617 |

| 10 | 63x1x10 | 63x1 | 630 | 541 | 844 | 1088 | 1296 | 1481 | 1646 | 1798 |

| 3 | 80x1x3 | 80x1 | 240 | 368 | 574 | 739 | 881 | 1006 | 1119 | 1221 |

| 4 | 80x1x4 | 80x1 | 320 | 423 | 660 | 851 | 1014 | 1158 | 1287 | 1406 |

| 5 | 80x1x5 | 80x1 | 400 | 471 | 735 | 947 | 1128 | 1289 | 1433 | 1565 |

| 6 | 80x1x6 | 80x1 | 480 | 513 | 801 | 1032 | 1229 | 1404 | 1562 | 1705 |

| 8 | 80x1x8 | 80x1 | 640 | 586 | 915 | 1179 | 1405 | 1604 | 1784 | 1948 |

| 10 | 80x1x10 | 80x1 | 800 | 649 | 1013 | 1305 | 1556 | 1777 | 1976 | 2157 |

| 5 | 100x1x5 | 100x1 | 500 | 565 | 882 | 1136 | 1354 | 1546 | 1720 | 1878 |

| 6 | 100x1x5 | 100x1 | 600 | 614 | 958 | 1235 | 1471 | 1681 | 1869 | 2041 |

| 8 | 100x1x8 | 100x1 | 800 | 699 | 1090 | 1404 | 1674 | 1912 | 2126 | 2321 |

| 10 | 100x1x10 | 100x1 | 1000 | 771 | 1203 | 1550 | 1848 | 2110 | 2347 | 2562 |

| 12 | 100x1x12 | 100x1 | 1200 | 836 | 1304 | 1680 | 2003 | 2287 | 2543 | 2777 |

Are you interested in this product? Do you need additional information or individual pricing?

Construction:

Elastic buses are made from copper tapes, protected by PCV(9mm do 50mm) which provides electric insulation even when the elastic connection is twisted or used in different environments(humidity, high temperature, aggressive surrounding)

Range:

-Standard length: 2000mm and 3000mm (other dimensions),

-tape thickness: 0,5 mm - 1mm,

-tape quantity: 2 - 12.

Options:

-Tinned copper or aluminium(or request)

-elastic connections

-non halogen,

-high temperature insulation: +125°C.

Advantages:

This is the only electrical connection system, which combine properties of connection shaping and conductor insulation. Connection work out costs are smaller because of material usage, which price is comparable to cables, connectors and casings.

Comparison -elastic bus to stiff bars:

-better electrical properties and bigger safety.

-Space profit because of closed assembly of elastic connections.

-Easy to shape because of flexibility.

Comparison - elastic buses to cables

-Time saving because of easier connection - no need to make additional connectors.

-No contact resistance, which occurs between cable and connector.

-Space profit.

-No casings or glands.

| Technical properties PVC: | ||

| -Density | 1,31 | NFT51-063, |

| -Shore hardness: | 85 A | NFT 51-109, |

| -Maximum resistance for stretching | 19,6 Mpa | NFT 51-034, |

| -maximum elongation | 365% | NFT 51-034, |

| -heat conductance: | 3 do 4 10-4cal/s/cm/°C, | |

| -dielectric withstand | 20 kV/mm, | |

| -fire demands | class FV 0 | UL 94v0, |

| -utilisation: | yes | |

| Tapes: | ||

| Copper classification: | according to NF A 51-050, | |

| -marking: | Cu-ETP marking O, | |

| -copper content: | 99,9%, | |

| -resistivity: | 1,7241 µΩ/cm. | |

| Copper properties | according to NF A 51-100, | |

| -resistance for stretching | 200 Mpa min, | |

| -elongation: | 30 % min, | |

| -thickness: | < 55 HV. | |

| Elastic busses : | ||

| -maximum voltage: | 1000V, | |

| -operation time: | -40°C do +105°C, | |

| -PVC thickness: | 2.0 mm, | |

| -dielectric withstand: | average 20kV/mm | according to NFC 32-201-1, |

| -flame resistance | according to NFC 32-070 C2. | |

| Markings | ||

| -ES: | elastic bus | |

| -24: | tape width [mm] | |

| -1: | tape thickness [mm] | |

| -8: | tape quantity |

Overheat of flexible elements is shown on a chart and table.

1 - Elastic bus

2 - Tape width (mm)

3 - Tape thickness (mm)

4 - Tape quantity (mm)

| Tape quantity | Dimensions [mm] |

Width x thickness [mm] |

Section [mm2] |

Overheat | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A 10 °C |

B 20 °C |

C 30 °C |

D 40 °C |

E 50 °C |

F 60 °C |

G 70 °C |

||||

| 2 | 9x0,8x2 | 9x0,8 | 14,4 | 47 | 74 | 95 | 114 | 130 | 144 | 157 |

| 3 | 9x0,8x3 | 9x0,8 | 21,6 | 59 | 92 | 119 | 141 | 162 | 180 | 196 |

| 6 | 9x0,8x6 | 9x0,8 | 43,2 | 88 | 137 | 176 | 210 | 240 | 266 | 291 |

| 9 | 9x0,8x9 | 9x0,8 | 64,8 | 112 | 174 | 225 | 268 | 306 | 340 | 371 |

| 2 | 13x0,5x2 | 13x0,5 | 13 | 48 | 75 | 97 | 116 | 132 | 147 | 160 |

| 3 | 13x0,5x3 | 13x0,5 | 19,5 | 60 | 93 | 120 | 143 | 163 | 181 | 198 |

| 4 | 13x0,5x4 | 13x0,5 | 26 | 69 | 108 | 140 | 166 | 190 | 211 | 231 |

| 6 | 13x0,5x6 | 13x0,5 | 39 | 87 | 135 | 174 | 207 | 237 | 263 | 288 |

| 10 | 13x0,5x10 | 13x0,5 | 65 | 115 | 180 | 232 | 276 | 316 | 351 | 383 |

| 2 | 15x0,8x2 | 15,5x0,8 | 24,8 | 70 | 110 | 141 | 168 | 192 | 214 | 234 |

| 3 | 15x0,8x3 | 15,5x0,8 | 37,2 | 87 | 136 | 175 | 209 | 239 | 265 | 290 |

| 4 | 15x0,8x4 | 15,5x0,8 | 49,6 | 102 | 159 | 205 | 244 | 279 | 310 | 339 |

| 6 | 15x0,8x6 | 15,5x0,8 | 74,4 | 128 | 199 | 257 | 306 | 350 | 389 | 424 |

| 8 | 15x0,8x8 | 15,5x0,8 | 99,2 | 151 | 235 | 303 | 361 | 412 | 458 | 501 |

| 10 | 15,5x0,8x10 | 15,5x0,8 | 124 | 172 | 268 | 345 | 411 | 470 | 523 | 571 |

| 2 | 20x1x2 | 20x1 | 40 | 96 | 150 | 193 | 230 | 263 | 292 | 319 |

| 3 | 20x1x3 | 20x1 | 60 | 119 | 186 | 240 | 286 | 326 | 263 | 396 |

| 4 | 20x1x4 | 20x1 | 80 | 139 | 217 | 280 | 334 | 381 | 424 | 463 |

| 5 | 20x1x5 | 20x1 | 100 | 158 | 246 | 317 | 377 | 431 | 479 | 523 |

| 6 | 20x1x6 | 20x1 | 120 | 174 | 272 | 351 | 418 | 477 | 531 | 580 |

| 8 | 20x1x8 | 20x1 | 160 | 205 | 321 | 413 | 492 | 562 | 325 | 683 |

| 10 | 20x1x10 | 20x1 | 200 | 234 | 365 | 470 | 560 | 640 | 711 | 777 |

| 11 | 20x1x11 | 20x1 | 220 | 247 | 386 | 497 | 592 | 676 | 752 | 821 |

| 2 | 24x1x2 | 24x1 | 48 | 111 | 173 | 223 | 265 | 303 | 337 | 368 |

| 3 | 24x1x3 | 24x1 | 72 | 137 | 214 | 276 | 329 | 375 | 417 | 456 |

| 4 | 24x1x4 | 24x1 | 96 | 160 | 250 | 322 | 383 | 438 | 487 | 532 |

| 5 | 24x1x5 | 24x1 | 120 | 181 | 282 | 363 | 433 | 494 | 550 | 600 |

| 6 | 24x1x6 | 24x1 | 144 | 200 | 312 | 402 | 479 | 547 | 608 | 664 |

| 8 | 24x1x8 | 24x1 | 192 | 234 | 366 | 471 | 562 | 641 | 713 | 779 |

| 10 | 24x1x10 | 24x1 | 240 | 266 | 415 | 534 | 637 | 727 | 809 | 883 |

| 2 | 32x1x2 | 32x1 | 64 | 139 | 218 | 280 | 334 | 382 | 424 | 463 |

| 3 | 32x1x3 | 32x1 | 96 | 172 | 269 | 346 | 413 | 471 | 524 | 572 |

| 4 | 32x1x4 | 32x1 | 128 | 200 | 313 | 403 | 480 | 548 | 610 | 666 |

| 5 | 32x1x5 | 32x1 | 160 | 226 | 352 | 453 | 540 | 617 | 686 | 749 |

| 6 | 32x1x6 | 32x1 | 192 | 249 | 388 | 500 | 596 | 680 | 756 | 826 |

| 8 | 32x1x8 | 32x1 | 256 | 290 | 452 | 695 | 695 | 793 | 882 | 963 |

| 10 | 32x1x10 | 32x1 | 320 | 327 | 510 | 657 | 783 | 894 | 995 | 1086 |

| Tape quantity | Dimensions [mm] |

Width x thickness [mm] |

Section [mm2] |

Overheat | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A 10 °C |

B 20 °C |

C 30 °C |

D 40 °C |

E 50 °C |

F 60 °C |

G 70 °C |

||||

| 2 | 40x1x2 | 40x1 | 80 | 167 | 261 | 337 | 401 | 458 | 510 | 556 |

| 3 | 40x1x3 | 40x1 | 120 | 206 | 322 | 415 | 494 | 565 | 628 | 686 |

| 4 | 40x1x4 | 40x1 | 160 | 240 | 374 | 481 | 574 | 655 | 729 | 796 |

| 6 | 40x1x5 | 40x1 | 200 | 269 | 420 | 541 | 644 | 736 | 818 | 894 |

| 6 | 40x1x6 | 40x1 | 240 | 296 | 461 | 594 | 708 | 809 | 900 | 982 |

| 8 | 40x1x8 | 40x1 | 320 | 243 | 535 | 690 | 822 | 939 | 1044 | 1140 |

| 10 | 40x1x10 | 40x1 | 400 | 285 | 601 | 774 | 922 | 1053 | 1171 | 1279 |

| 3 | 50x1x3 | 50x1 | 150 | 248 | 387 | 498 | 594 | 679 | 755 | 824 |

| 4 | 50x1x4 | 50x1 | 200 | 287 | 448 | 577 | 688 | 786 | 874 | 954 |

| 5 | 50x1x5 | 50x1 | 250 | 322 | 502 | 646 | 770 | 880 | 987 | 1068 |

| 6 | 50x1x6 | 50x1 | 300 | 352 | 550 | 709 | 844 | 965 | 1073 | 1171 |

| 8 | 50x1x8 | 50x1 | 400 | 407 | 635 | 818 | 975 | 1114 | 1238 | 1352 |

| 10 | 50x1x10 | 50x1 | 500 | 455 | 709 | 914 | 1089 | 1244 | 1383 | 1510 |

| 3 | 63x1x3 | 63x1 | 189 | 301 | 469 | 604 | 720 | 823 | 915 | 999 |

| 4 | 63x1x4 | 63x1 | 252 | 347 | 542 | 698 | 832 | 950 | 1056 | 1153 |

| 5 | 63x1x5 | 63x1 | 315 | 388 | 605 | 779 | 929 | 1061 | 1179 | 1288 |

| 6 | 63x1x6 | 63x1 | 378 | 424 | 661 | 852 | 1015 | 1159 | 1289 | 1408 |

| 8 | 63x1x8 | 63x1 | 504 | 487 | 759 | 978 | 1166 | 1332 | 1481 | 1617 |

| 10 | 63x1x10 | 63x1 | 630 | 541 | 844 | 1088 | 1296 | 1481 | 1646 | 1798 |

| 3 | 80x1x3 | 80x1 | 240 | 368 | 574 | 739 | 881 | 1006 | 1119 | 1221 |

| 4 | 80x1x4 | 80x1 | 320 | 423 | 660 | 851 | 1014 | 1158 | 1287 | 1406 |

| 5 | 80x1x5 | 80x1 | 400 | 471 | 735 | 947 | 1128 | 1289 | 1433 | 1565 |

| 6 | 80x1x6 | 80x1 | 480 | 513 | 801 | 1032 | 1229 | 1404 | 1562 | 1705 |

| 8 | 80x1x8 | 80x1 | 640 | 586 | 915 | 1179 | 1405 | 1604 | 1784 | 1948 |

| 10 | 80x1x10 | 80x1 | 800 | 649 | 1013 | 1305 | 1556 | 1777 | 1976 | 2157 |

| 5 | 100x1x5 | 100x1 | 500 | 565 | 882 | 1136 | 1354 | 1546 | 1720 | 1878 |

| 6 | 100x1x5 | 100x1 | 600 | 614 | 958 | 1235 | 1471 | 1681 | 1869 | 2041 |

| 8 | 100x1x8 | 100x1 | 800 | 699 | 1090 | 1404 | 1674 | 1912 | 2126 | 2321 |

| 10 | 100x1x10 | 100x1 | 1000 | 771 | 1203 | 1550 | 1848 | 2110 | 2347 | 2562 |

| 12 | 100x1x12 | 100x1 | 1200 | 836 | 1304 | 1680 | 2003 | 2287 | 2543 | 2777 |

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent