Category

Photos are for informational purposes only. View product specification

please use latin characters

|

Characteristics • Continuous operating temperatures: -90 °C to +205 °C• Excellent resistance to aggressive chemical environments. • Excellent resistance to humidity and UV • Excellent mechanical strength. • Rated voltage: 450/750 V • Test voltage: 2500 V Standard products • All colours including translucent.Approvals - standards • Series inspired by standards NF C 93-524 and DIN VDE 0250 Part 106.Applications • Cabling for rotating machines. Options • Nickel-plated copper core: ref. CNFEP.• Silver-plated copper core: ref. AFEP. • Pure nickel core: ref. NFEP. • Outer electrical shielding: > Tin-plated copper braid: ref. FEPBE or EFEPBE. • Other nominal metric or American cross-sections: contact us. • Other nominal stranding: contact us. • Other options and/or combinations of the options outlined above: contact us. |

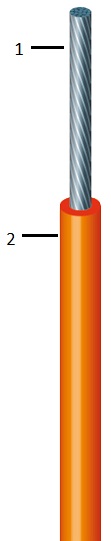

1 • Bare (ref. FEP) or tin-plated (ref. EFEP) copper core. |

CONDUCTING CORE |

INSULATED WIRE OR CABLE |

||||

|---|---|---|---|---|---|

| Nominal cross-section [mm2] |

Nominal stranding | Maximum linear resistance at 20 °C (Ω/km) (bare copper core) | Nominal thickness of insulation (mm | Nominal diameter (mm | Approximate linear weight (kg/km) |

| 0,05 | 7 x 0,10 | 373 | 0,17 | 0,65 | 1,1 |

| 0,09 | 7 x 0,13 | 214 | 0,17 | 0,7 | 1,4 |

| 0,12* | 7 x 0,15 | 161 | 0,17 | 0,8 | 1,9 |

| 0,14** | 7 x 0,16 | 141 | 0,17 | 0,8 | 2,0 |

| 0,15 | 19 x 0,10 | 136 | 0,20 | 0,9 | 2,3 |

| 0,22 | 7 x 0,20 | 89,9 | 0,20 | 1,0 | 3,0 |

| 0,25 | 19 x 0,13 | 80,0 | 0,20 | 1,05 | 3,4 |

| 0,34 | 7 x 0,25 | 57,5 | 0,20 | 1,15 | 4,3 |

| 0,38** | 19 x 0,16 | 54,1 | 0,20 | 1,15 | 4,6 |

| 0,5 | 7 x 0,30 | 39,6 | 0,20 | 1,3 | 5,9 |

| 0,5 | 16 x 0,20 | 39,0 | 0,20 | 1,3 | 6,2 |

| 0,6 | 19 x 0,20 | 32,8 | 0,20 | 1,4 | 6,7 |

| 0,75 | 24 x 0,20 | 26,0 | 0,20 | 1,45 | 8,8 |

| 0,88 | 7 x 0,40 | 22,2 | 0,20 | 1,5 | 9,3 |

| 0,93 | 19 x 0,25 | 21,0 | 0,20 | 1,7 | 10,5 |

| 1 | 32 x 0,20 | 19,5 | 0,20 | 1,7 | 11,9 |

| 1,34 | 19 x 0,30 | 14,6 | 0,20 | 1,9 | 14,3 |

| 1,5 | 30 x 0,25 | 13,3 | 0,20 | 1,95 | 16,3 |

| 2,5 | 50 x 0,25 | 7,98 | 0,20 | 2,5 | 26,6 |

| 4 | 56 x 0,30 | 4,95 | 0,25 | 3,1 | 40,4 |

| 6 | 84 x 0,30 | 3,30 | 0,35 | 3,9 | 57,7 |

| 10 | 80 x 0,40 | 1,91 | 0,40 | 5,2 | 104 |

| 16 | 126 x 0,40 | 1,21 | 0,40 | 6,2 | 150 |

| 25 | 196 x 0,40 | 0,780 | 0,60 | 8,2 | 248 |

| 35 | 276 x 0,40 | 0,554 | 0,60 | 9,2 | 328 |

| 50 | 396 x 0,40 | 0,386 | 0,70 | 11,2 | 478 |

* Nominal cross-section not available with the ref. EFEP

** Nominal cross-sections not available with the ref. FEP.

Are you interested in this product? Do you need additional information or individual pricing?

|

Characteristics • Continuous operating temperatures: -90 °C to +205 °C• Excellent resistance to aggressive chemical environments. • Excellent resistance to humidity and UV • Excellent mechanical strength. • Rated voltage: 450/750 V • Test voltage: 2500 V Standard products • All colours including translucent.Approvals - standards • Series inspired by standards NF C 93-524 and DIN VDE 0250 Part 106.Applications • Cabling for rotating machines. Options • Nickel-plated copper core: ref. CNFEP.• Silver-plated copper core: ref. AFEP. • Pure nickel core: ref. NFEP. • Outer electrical shielding: > Tin-plated copper braid: ref. FEPBE or EFEPBE. • Other nominal metric or American cross-sections: contact us. • Other nominal stranding: contact us. • Other options and/or combinations of the options outlined above: contact us. |

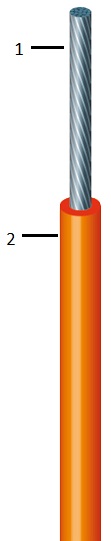

1 • Bare (ref. FEP) or tin-plated (ref. EFEP) copper core. |

CONDUCTING CORE |

INSULATED WIRE OR CABLE |

||||

|---|---|---|---|---|---|

| Nominal cross-section [mm2] |

Nominal stranding | Maximum linear resistance at 20 °C (Ω/km) (bare copper core) | Nominal thickness of insulation (mm | Nominal diameter (mm | Approximate linear weight (kg/km) |

| 0,05 | 7 x 0,10 | 373 | 0,17 | 0,65 | 1,1 |

| 0,09 | 7 x 0,13 | 214 | 0,17 | 0,7 | 1,4 |

| 0,12* | 7 x 0,15 | 161 | 0,17 | 0,8 | 1,9 |

| 0,14** | 7 x 0,16 | 141 | 0,17 | 0,8 | 2,0 |

| 0,15 | 19 x 0,10 | 136 | 0,20 | 0,9 | 2,3 |

| 0,22 | 7 x 0,20 | 89,9 | 0,20 | 1,0 | 3,0 |

| 0,25 | 19 x 0,13 | 80,0 | 0,20 | 1,05 | 3,4 |

| 0,34 | 7 x 0,25 | 57,5 | 0,20 | 1,15 | 4,3 |

| 0,38** | 19 x 0,16 | 54,1 | 0,20 | 1,15 | 4,6 |

| 0,5 | 7 x 0,30 | 39,6 | 0,20 | 1,3 | 5,9 |

| 0,5 | 16 x 0,20 | 39,0 | 0,20 | 1,3 | 6,2 |

| 0,6 | 19 x 0,20 | 32,8 | 0,20 | 1,4 | 6,7 |

| 0,75 | 24 x 0,20 | 26,0 | 0,20 | 1,45 | 8,8 |

| 0,88 | 7 x 0,40 | 22,2 | 0,20 | 1,5 | 9,3 |

| 0,93 | 19 x 0,25 | 21,0 | 0,20 | 1,7 | 10,5 |

| 1 | 32 x 0,20 | 19,5 | 0,20 | 1,7 | 11,9 |

| 1,34 | 19 x 0,30 | 14,6 | 0,20 | 1,9 | 14,3 |

| 1,5 | 30 x 0,25 | 13,3 | 0,20 | 1,95 | 16,3 |

| 2,5 | 50 x 0,25 | 7,98 | 0,20 | 2,5 | 26,6 |

| 4 | 56 x 0,30 | 4,95 | 0,25 | 3,1 | 40,4 |

| 6 | 84 x 0,30 | 3,30 | 0,35 | 3,9 | 57,7 |

| 10 | 80 x 0,40 | 1,91 | 0,40 | 5,2 | 104 |

| 16 | 126 x 0,40 | 1,21 | 0,40 | 6,2 | 150 |

| 25 | 196 x 0,40 | 0,780 | 0,60 | 8,2 | 248 |

| 35 | 276 x 0,40 | 0,554 | 0,60 | 9,2 | 328 |

| 50 | 396 x 0,40 | 0,386 | 0,70 | 11,2 | 478 |

* Nominal cross-section not available with the ref. EFEP

** Nominal cross-sections not available with the ref. FEP.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent