Category

Photos are for informational purposes only. View product specification

please use latin characters

The Only Rule...The Path to Optimal Security

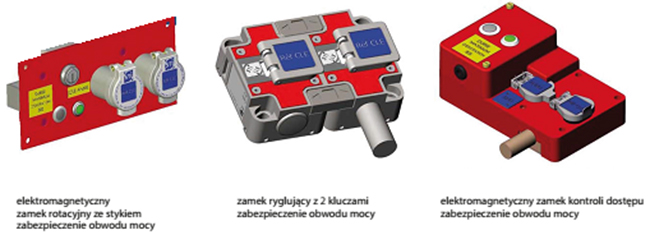

All locking systems operate according to the key transfer principle. Given that a given application's key cannot open two locks simultaneously, the system forces the operator to perform pre-determined actions to allow entry into the danger zone. Using this system ensures maximum safety for employees.

SYSTEM BENEFITS

- reduces the number of accidents

- is simple and quick to install

- forces adherence to a pre-determined sequence of activities related to machine operation.

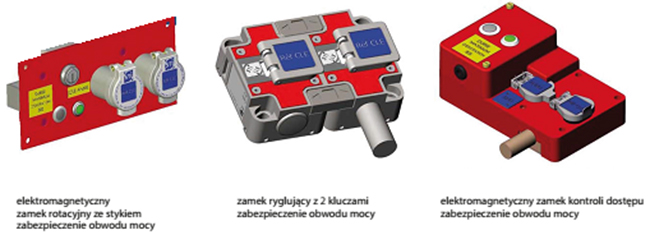

Security systems using locks and access control locks are characterized by easy and quick installation and simplicity of use. Due to their solid construction, high durability and longevity, and the quality of the materials used (INOX stainless steel), the locks are used in difficult and aggressive environments (dust, vibration). The main industries where safety systems using locks are installed include: the energy industry (power plants, combined heat and power plants, switching stations, electrostatic precipitators), the construction industry (cement plants, concrete plants, crushers), the metallurgical industry (furnaces, rollers, overhead cranes), the chemical and petrochemical industry (valve locks, mixers), the plastics industry (mixers, extruders, presses), as well as the food, automotive, and wood and paper industries.

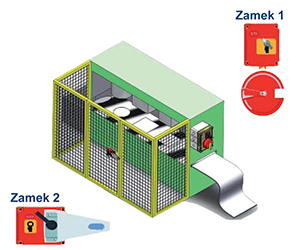

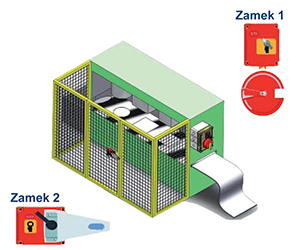

Example Locked System

The operator disconnects the voltage and locks the switch before entering the hazard zone.

| Operational Description | Lock 1 | Lock 2 |

|---|---|---|

| MACHINE IN MOTION - switch in the ON position - lock 1, bolt hidden, key locked - lock 2, element locked in the lock - access to the hazard zone impossible |

|

|

| Stage 1: STOPPING THE MACHINE - switch in the OFF position - lock 1: bolt hidden, key blocked, key maneuvering possible - lock 2: access to the hazard zone blocked - access to the hazard zone impossible |

|

|

| Step 2: KEY TRANSFER -switch in the OFF position -lock 1: bolt extended, switch locked, key released -key transfer from lock 1 to Lock 2 - Machine shutdown |

|

|

| Stage 3: AUTHORIZED ACCESS TO THE MACHINE - Switch in the OFF position - Lock 1: Bolt extended - Lock 2: Key locked, key manipulation possible - Access to the machine slow, machine cannot be started |

|

|

| Step 4: PERFORMING MACHINE SERVICE OPERATIONS - Switch in the OFF position - Lock 1: bolt extended - Lock 2: key jammed in the lock, locked element released, access to the hazard zone free |

|

|

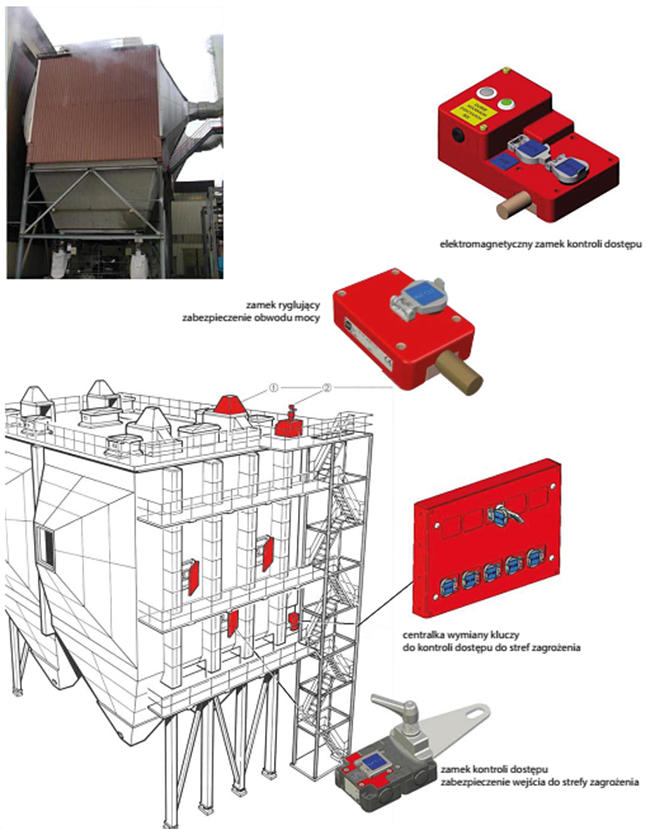

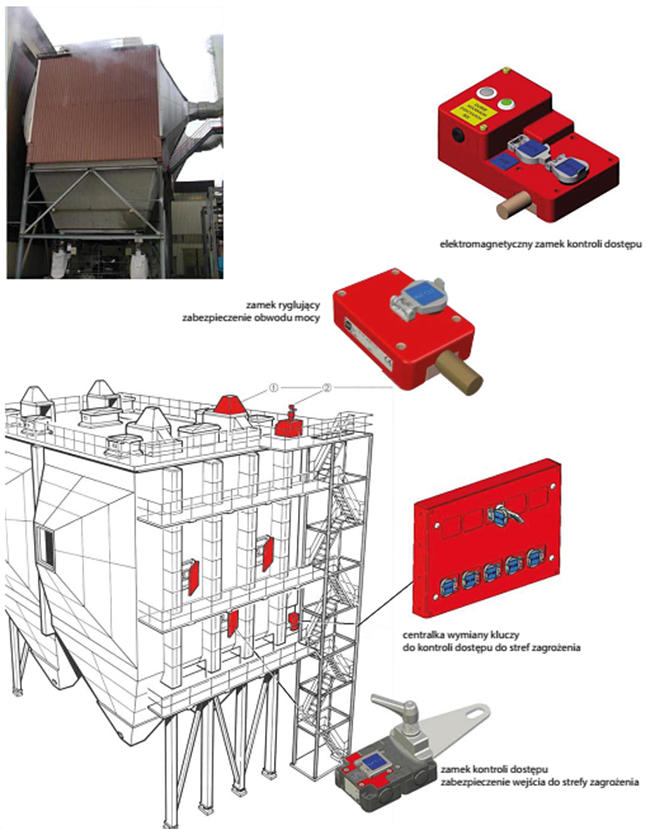

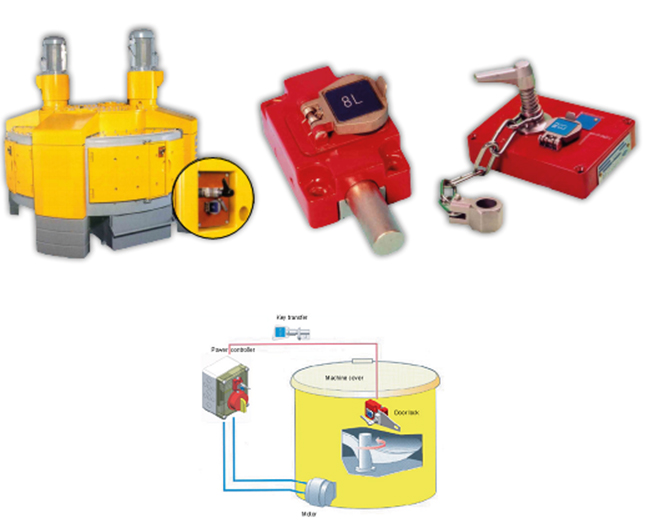

An access control system involves installing locking locks on main switches and disconnector-earthing switches, as well as access control locks on manholes to the electrostatic precipitator. The system forces the operator to turn off the voltage and ground before entering the electrostatic precipitator cell.

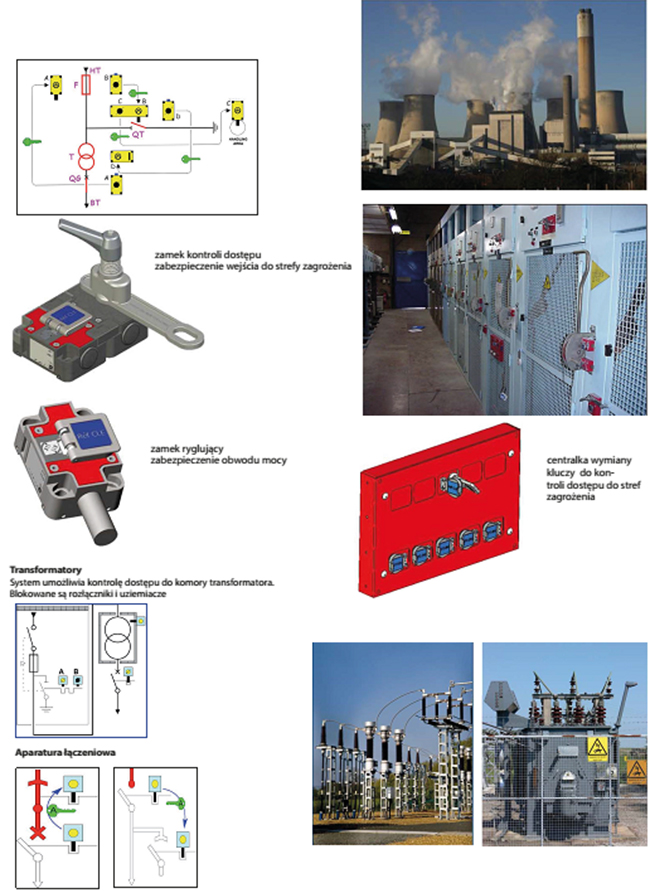

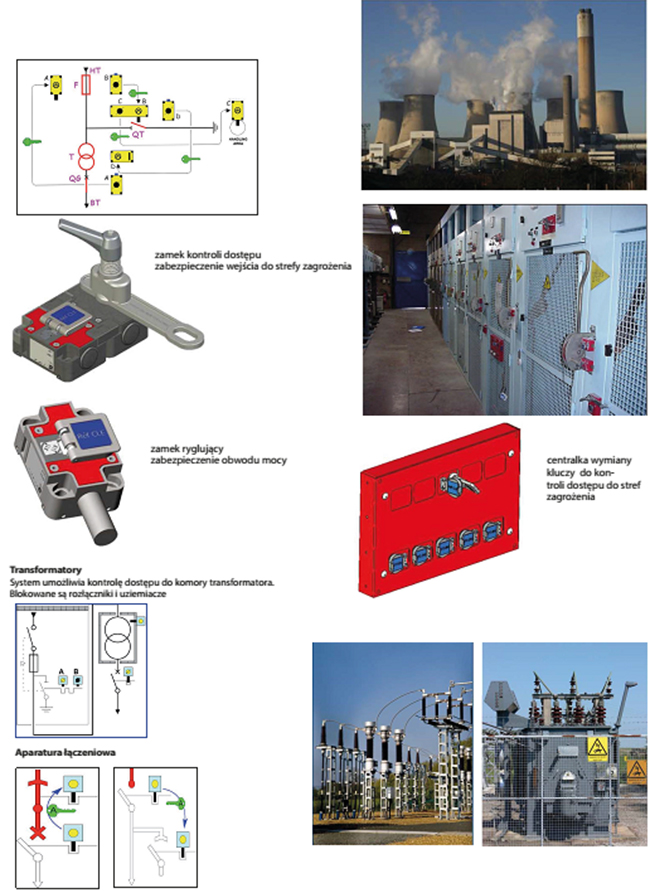

Switchboards

The access control system introduces a sequence that the operator must follow to safely perform switching operations.

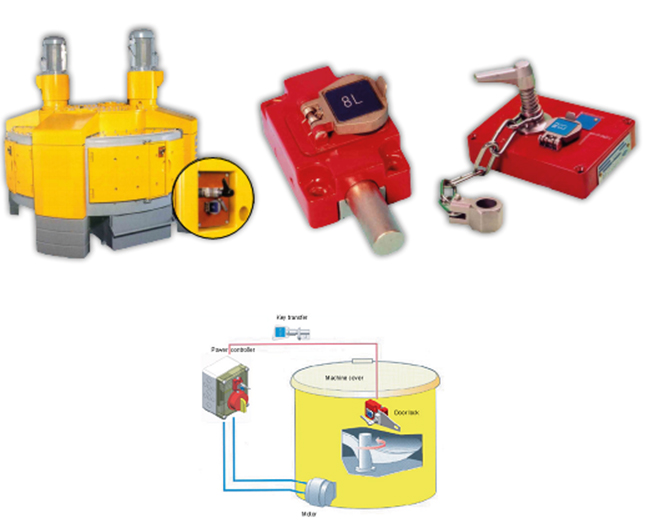

An access control system installed in a mixer or crusher prevents the machine from being turned on when the door is open and an operator (performing maintenance) is inside.

Are you interested in this product? Do you need additional information or individual pricing?

The Only Rule...The Path to Optimal Security

All locking systems operate according to the key transfer principle. Given that a given application's key cannot open two locks simultaneously, the system forces the operator to perform pre-determined actions to allow entry into the danger zone. Using this system ensures maximum safety for employees.

SYSTEM BENEFITS

- reduces the number of accidents

- is simple and quick to install

- forces adherence to a pre-determined sequence of activities related to machine operation.

Security systems using locks and access control locks are characterized by easy and quick installation and simplicity of use. Due to their solid construction, high durability and longevity, and the quality of the materials used (INOX stainless steel), the locks are used in difficult and aggressive environments (dust, vibration). The main industries where safety systems using locks are installed include: the energy industry (power plants, combined heat and power plants, switching stations, electrostatic precipitators), the construction industry (cement plants, concrete plants, crushers), the metallurgical industry (furnaces, rollers, overhead cranes), the chemical and petrochemical industry (valve locks, mixers), the plastics industry (mixers, extruders, presses), as well as the food, automotive, and wood and paper industries.

Example Locked System

The operator disconnects the voltage and locks the switch before entering the hazard zone.

| Operational Description | Lock 1 | Lock 2 |

|---|---|---|

| MACHINE IN MOTION - switch in the ON position - lock 1, bolt hidden, key locked - lock 2, element locked in the lock - access to the hazard zone impossible |

|

|

| Stage 1: STOPPING THE MACHINE - switch in the OFF position - lock 1: bolt hidden, key blocked, key maneuvering possible - lock 2: access to the hazard zone blocked - access to the hazard zone impossible |

|

|

| Step 2: KEY TRANSFER -switch in the OFF position -lock 1: bolt extended, switch locked, key released -key transfer from lock 1 to Lock 2 - Machine shutdown |

|

|

| Stage 3: AUTHORIZED ACCESS TO THE MACHINE - Switch in the OFF position - Lock 1: Bolt extended - Lock 2: Key locked, key manipulation possible - Access to the machine slow, machine cannot be started |

|

|

| Step 4: PERFORMING MACHINE SERVICE OPERATIONS - Switch in the OFF position - Lock 1: bolt extended - Lock 2: key jammed in the lock, locked element released, access to the hazard zone free |

|

|

An access control system involves installing locking locks on main switches and disconnector-earthing switches, as well as access control locks on manholes to the electrostatic precipitator. The system forces the operator to turn off the voltage and ground before entering the electrostatic precipitator cell.

Switchboards

The access control system introduces a sequence that the operator must follow to safely perform switching operations.

An access control system installed in a mixer or crusher prevents the machine from being turned on when the door is open and an operator (performing maintenance) is inside.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent