trebuie să fii logat

Category

Fotografiile au doar scop informativ. Vizualizați specificațiile produsului

please use latin characters

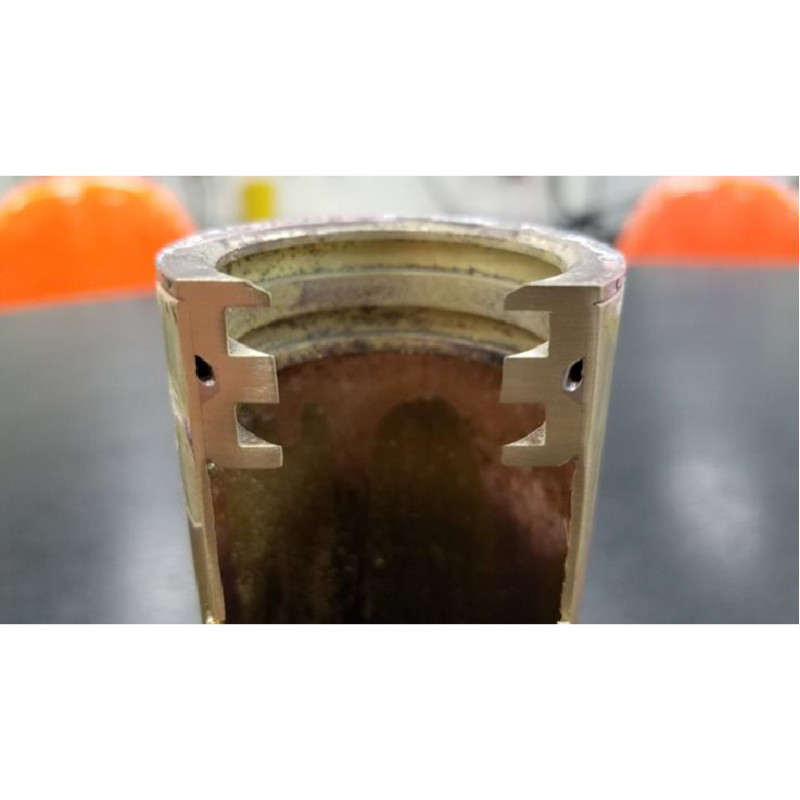

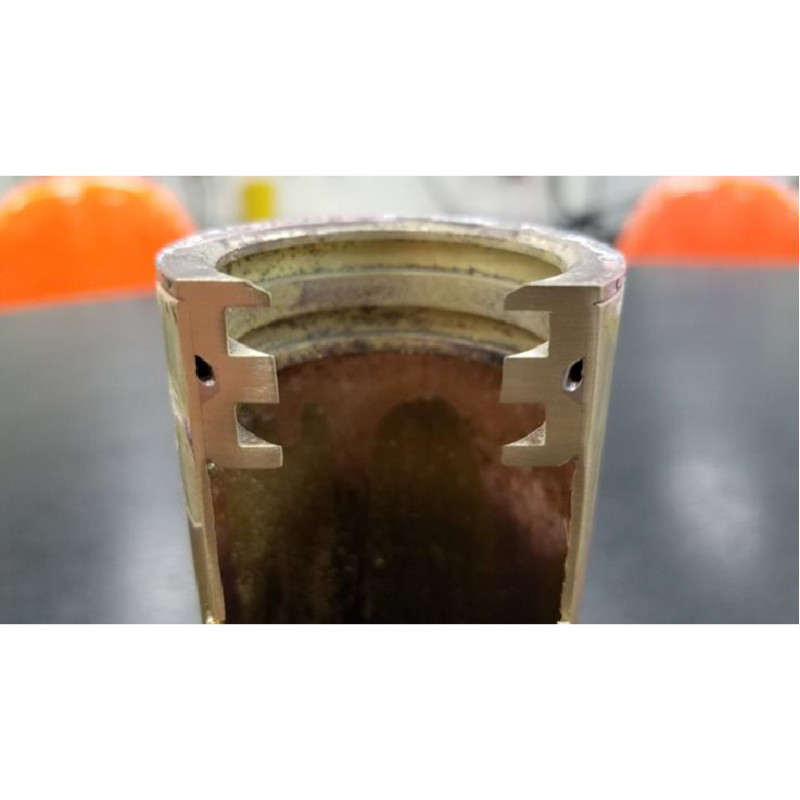

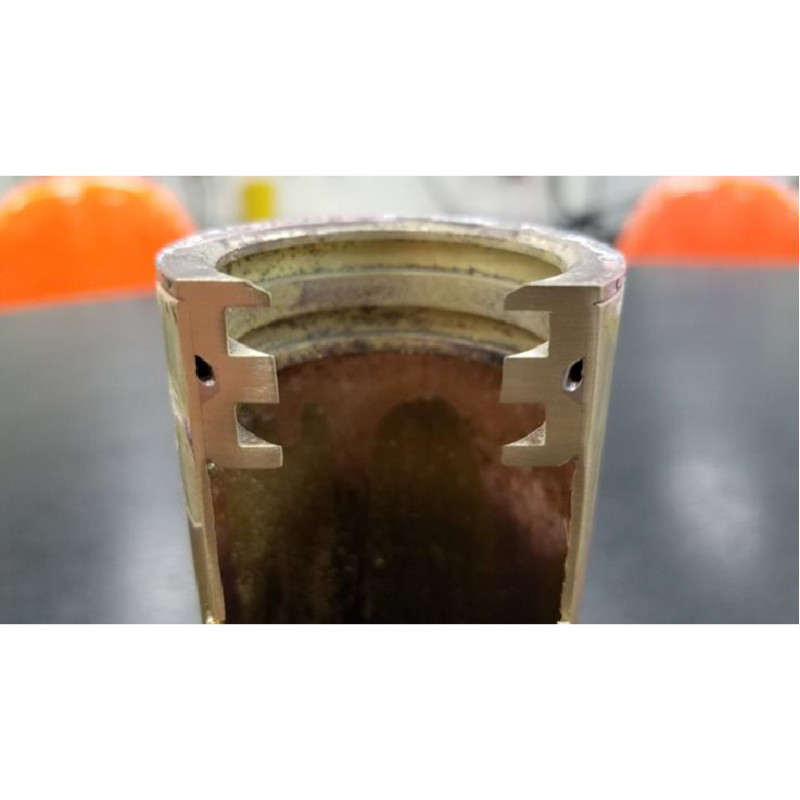

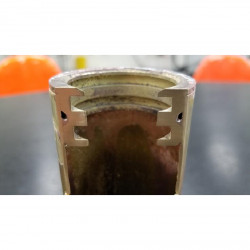

Objective: To heat brass assemblies for a brazing application; the client had been using a torch and is a manufacturer of sink products.

Frequency: 316 kHz

Material: Brass assemblies (2”/51 mm OD)

Temperature: 1425 °F (773 °C)

A custom-designed single position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. It took two minutes to heat the 2”/51 mm OD brass assembly to temperature.

Sunteți interesat de acest produs? Aveți nevoie de informații suplimentare sau de prețuri individuale?

trebuie să fii logat

Objective: To heat brass assemblies for a brazing application; the client had been using a torch and is a manufacturer of sink products.

Frequency: 316 kHz

Material: Brass assemblies (2”/51 mm OD)

Temperature: 1425 °F (773 °C)

A custom-designed single position multiple-turn helical coil was built to generate the required heating for the application. Initial tests were conducted to optimize the power delivered to the part. It took two minutes to heat the 2”/51 mm OD brass assembly to temperature.

Aprecierea ta pentru recenzie nu a putut fi trimisa

Reclama un comentariu

Raport trimis

Reclamatia tau nu a putut fi trimisa

Scrie-ti recenzia

Recenzia a fost trimisa

Recenzia ta nu a putut fi trimisa