Морате бити пријављени да

Штампана електроника

Šta je štampana elektronika (PE)?

Štampana elektronika (PE – od engl. Printed Electronics) je savremena tehnologija proizvodnje elektronskih kola korišćenjem procesa štampe na različitim podlogama – kako čvrstim, tako i fleksibilnim. Zahvaljujući upotrebi provodnih materijala, kao što su srebrno mastilo, provodne boje ili indijum-kalaj-oksid (ITO), postaje moguće kreirati fleksibilna štampana kola, minijaturne matrične elektrode i elektronske komponente visoke preciznosti.

Štampana elektronika omogućava proizvodnju lakih, tankih i kompaktnih kola koja se lako mogu integrisati u elektronske sisteme, uključujući IoT uređaje, kućne aparate ili medicinska rešenja. Ova inovativna tehnologija ne samo da omogućava optimizaciju troškova proizvodnje, već otvara i nove mogućnosti za dizajniranje uređaja složenih oblika i funkcija.

Kratka istorija i razvoj tehnologije štampane elektronike

Počeci štampane elektronike datiraju iz 60-ih i 70-ih godina prošlog veka, kada su naučnici počeli da eksperimentišu sa nanošenjem provodnih mastila na podloge radi kreiranja jednostavnih kola. Tokom narednih decenija, ova tehnologija se razvijala u laboratorijama, a njena primena se postepeno proširila na medicinsku, automobilsku industriju i potrošačku elektroniku.

Razvoj metoda štampe, kao što su sito štampa, rotaciona sito štampa ili aditivne tehnologije, omogućio je proizvodnju složenijih sistema i fleksibilnih štampanih ploča (FPC). Kao rezultat toga, štampana elektronika je prešla put od nišnih eksperimenata do stvarnih industrijskih i komercijalnih primena, postajući ključni element moderne elektronske industrije.

Sve veća popularnost štampane elektronike na svetskom tržištu

Poslednjih godina štampana elektronika je stekla ogromnu popularnost na svetskom tržištu. Sve više kompanija investira u razvoj inovativnih uređaja koristeći fleksibilna štampana kola i savremene provodne materijale. Štampana elektronika omogućava proizvodnju elektronskih komponenti uz niže troškove i veću preciznost, što povećava njenu privlačnost u automobilskom, medicinskom sektoru, IoT-u i kućnim aparatima.

Tržište štampane elektronike dinamično raste, a prognoze ukazuju da će se ovaj trend nastaviti. Popularnost ove tehnologije proizilazi ne samo iz proizvodnih prednosti, već i iz mogućnosti kreiranja novih, inovativnih rešenja koja je ranije bilo teško ili nemoguće realizovati tradicionalnim metodama.

Tehnologije proizvodnje štampane elektronike

Sito štampa i rotaciona sito štampa

Jedna od najčešće korišćenih metoda u štampanoj elektronici je sito štampa, koja omogućava precizno nanošenje provodnih mastila na fleksibilne ili čvrste podloge. Proces se sastoji u potiskivanju provodnog materijala kroz mrežicu, što omogućava kreiranje tankih i izdržljivih provodnih staza.

Za masovnu proizvodnju i složenije sisteme koristi se rotaciona sito štampa, koja omogućava brzu štampu na fleksibilnim folijama i tabacima, uz zadržavanje visoke preciznosti. Ove tehnologije omogućavaju proizvodnju fleksibilnih štampanih kola (FPC) i komponenti štampane elektronike koje se koriste u medicini, IoT-u ili automobilskoj industriji.

Aditivne metode i proces štampe kola

Pored sito štampe, u proizvodnji štampane elektronike sve češće se koriste aditivne metode, koje se sastoje u nanošenju provodnog materijala samo tamo gde je to neophodno. Zahvaljujući tome, količina otpada je minimizirana, a efikasnost proizvodnje raste.

Proces štampe kola aditivnim metodama omogućava kreiranje minijaturnih matričnih elektroda, senzora ili naprednih elektronskih komponenti. Štampana rešenja nude veliku fleksibilnost u dizajnu, omogućavajući njihovu integraciju u uređaje sa nekonvencionalnim oblicima i površinama.

Integracija tehnologija štampe u proizvodnju IoT uređaja

Štampana elektronika se odlično pokazuje u projektima vezanim za Internet stvari (IoT). Zahvaljujući fleksibilnim štampanim kolima, moguće je lako povezivanje senzora, antena i drugih komponenti u inteligentne sisteme.

Integracija tehnologija štampe u proizvodnju IoT uređaja omogućava brzo prototipovanje i uvođenje novih proizvoda na tržište, kao i kreiranje inovativnih rešenja u medicinskom sektoru, kućnim aparatima ili automobilskoj industriji. Štampana elektronska kola omogućavaju kreiranje kompaktnih, lakih i izdržljivih sistema koje bi bilo teško postići tradicionalnim metodama montaže.

Poređenje tehnologija i njihove prednosti

Svaka od metoda proizvodnje štampane elektronike ima svoje prednosti:

-

Sito štampa – visoka preciznost, idealna za tanke staze i standardne primene.

-

Rotaciona sito štampa – brza štampa na velikim površinama, efikasna u masovnoj proizvodnji.

-

Aditivne metode – minimiziranje otpada, mogućnost kreiranja složenih i specifičnih oblika.

Zahvaljujući kombinaciji ovih tehnologija, kompanije poput DACPOL-a mogu pružiti fleksibilna rešenja u oblasti štampane elektronike, prilagođena individualnim potrebama klijenata, podržavajući proizvodnju inovativnih elektronskih uređaja i sistema.

Podloge i materijali u štampanoj elektronici

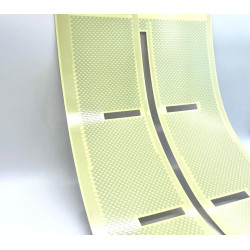

Fleksibilne podloge (PET, polimerne folije)

Podloga je jedan od ključnih elemenata u štampanoj elektronici, jer određuje izdržljivost, fleksibilnost i mogućnosti integracije kola u uređaje. Najčešće se koriste fleksibilne podloge, kao što su PET (poliester) ili polimerne folije, koje kombinuju malu težinu sa visokom mehaničkom otpornošću.

Fleksibilne podloge omogućavaju kreiranje štampanih kola prilagođenih zakrivljenim površinama, što je posebno važno u medicini, tekstilnoj industriji ili kod IoT uređaja. Zahvaljujući njima, štampana kola mogu biti istovremeno fleksibilna i dugotrajna, što povećava pouzdanost elektronskih uređaja.

Provodni materijali: srebrna mastila, provodne boje, indijum-kalaj-oksid (ITO)

U tehnologiji štampane elektronike, provodni materijali igraju presudnu ulogu jer obezbeđuju protok struje u sistemu. Među najčešće korišćenim su:

-

Srebrno mastilo – pruža visoku provodljivost i lako se nanosi metodom sito štampe.

-

Provodne boje – fleksibilne, koriste se u specijalizovanim primenama, uključujući nosivu elektroniku (wearables).

-

Indijum-kalaj-oksid (ITO) – transparentni provodni materijal koji se koristi u ekranima i optoelektronskim senzorima.

Izbor odgovarajućih provodnih materijala omogućava kreiranje efikasnih i pouzdanih kola koja zadržavaju svoje električne parametre čak i nakon višestrukog savijanja.

U medicinskom sektoru, štampana elektronika zahteva upotrebu biokompatibilnih kompozita koji su bezbedni u kontaktu sa ljudskim telom. Ovi materijali omogućavaju kreiranje štampanih medicinskih senzora, dijagnostičkih uređaja ili pametnih narukvica za praćenje zdravstvenog stanja pacijenata.

Specijalizovani materijali za medicinu takođe osiguravaju visoku trajnost i otpornost na hemijske faktore, neophodne u laboratorijskim i kliničkim okruženjima.

Uticaj materijala na pouzdanost elektronskih uređaja

Izbor odgovarajućih podloga i provodnih materijala ima direktan uticaj na pouzdanost elektronskih uređaja. Fleksibilne podloge i visokokvalitetna provodna mastila smanjuju rizik od mehaničkih oštećenja, poboljšavaju otpornost na savijanje i olakšavaju integraciju sa IoT sistemima i drugim elektronskim komponentama.

Dobro odabrani materijali takođe omogućavaju proizvodnju uređaja sa dugim vekom trajanja i stabilnošću električnih parametara, što je kritično u industrijskim, automobilskim i medicinskim primenama.

Konstrukcija i komponente štampane elektronike

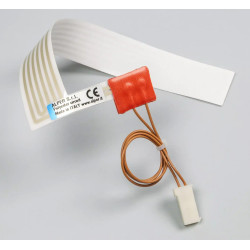

Fleksibilna štampana kola i minijaturne matrične elektrode

Osnovni element tehnologije štampane elektronike su fleksibilna štampana kola (FPC), koja omogućavaju kreiranje tankih, lakih i savitljivih veza. Zahvaljujući njima, elektronika se može prilagoditi neobičnim oblicima i zakrivljenim površinama, što je izuzetno važno u medicini, IoT-u ili pametnoj odeći.

Minijaturne matrične elektrode omogućavaju integraciju mnogih funkcija u jedan modul, nudeći mogućnost dizajniranja kompaktnih i naprednih elektronskih uređaja. Takva rešenja povećavaju fleksibilnost dizajna i olakšavaju razvoj novih proizvoda.

Komponente štampane elektronike i elektronski elementi

Štampana elektronika obuhvata širok spektar elektronskih komponenti, kao što su senzori, membrane, provodne staze, displeji i elementi za upravljanje. Zahvaljujući preciznom procesu štampe, svaka komponenta može biti savršeno prilagođena funkciji koju treba da obavlja u uređaju.

U kombinaciji sa fleksibilnim štampanim pločama, komponente štampane elektronike omogućavaju kreiranje minijaturnih, lakih i efikasnih elektronskih sistema koje bi bilo teško realizovati tradicionalnim metodama montaže.

Rešenja u oblasti štampane elektronike za različite industrije

Štampana elektronika nalazi primenu u mnogim oblastima:

-

Medicina – štampani senzori i dijagnostički uređaji.

-

Automobilska industrija – fleksibilne provodne trake koje zamenjuju tradicionalne kablovske snopove.

-

IoT i potrošačka elektronika – inteligentni sistemi, wearables, gadžeti za praćenje.

-

Industrija – senzori i kontrolni moduli u industrijskim mašinama.

Ova široka primenljivost štampane elektronike omogućava kompanijama da ponude klijentima rešenja prilagođena individualnim potrebama i specifičnostima njihove industrije.

Štampana rešenja koja nude nove mogućnosti dizajna

Jedna od najvećih prednosti štampane elektronike je otvaranje novih mogućnosti dizajna. Štampana rešenja omogućavaju kreiranje fleksibilnih, lakih i visoko funkcionalnih kola koja mogu obavljati više funkcija unutar jednog modula.

Zahvaljujući tome, dizajneri mogu realizovati ideje koje su ranije bile nemoguće za sprovođenje tradicionalnim elektronskim tehnologijama. Štampana rešenja takođe nude brzo prototipovanje, laku integraciju sa IoT sistemima i mogućnost kreiranja inovativnih proizvoda za potrošačko i industrijsko tržište.

Primene štampane elektronike

Štampana elektronika u medicini: štampa medicinskih senzora i dijagnostičkih uređaja

Štampana elektronika se široko koristi u medicini. Upotrebom biokompatibilnih kompozita i fleksibilnih podloga, moguće je kreirati štampane medicinske senzore koji prate vitalne parametre pacijenata u realnom vremenu.

Pored toga, tehnologija štampane elektronike omogućava proizvodnju dijagnostičkih uređaja koji su laki, kompaktni i jednostavni za integraciju u kliničko okruženje. Ova rešenja povećavaju udobnost pacijenata i olakšavaju rad medicinskom osoblju, dok istovremeno omogućavaju kreiranje inovativnih proizvoda u medicinskoj industriji.

Primene u automobilskoj industriji, kućnim aparatima, avijaciji i kosmonautici

Štampana elektronska kola osvajaju i industrijsko tržište. U automobilskoj industriji, fleksibilna štampana kola zamenjuju tradicionalno ožičenje, smanjujući težinu vozila i povećavajući pouzdanost elektronskih sistema.

U kućnim aparatima, štampana elektronika omogućava kreiranje kompaktnih i preciznih sistema upravljanja. U sektoru avijacije i kosmonautike, upotreba fleksibilnih štampanih veza omogućava dizajn lakih sistema za nadzor, senzora i kontrolnih modula koji moraju izdržati ekstremne uslove rada.

Štampana elektronika u IoT-u i pametnoj odeći

Zahvaljujući mogućnosti integracije sa IoT (Internet of Things) sistemima, štampana elektronika omogućava kreiranje inteligentnih uređaja za svakodnevnu upotrebu – od ekoloških senzora do nosive elektronike.

U pametnoj odeći, štampana elektronska kola omogućavaju ugradnju funkcija za praćenje zdravlja, temperaturnih senzora ili kontrolnih elemenata bez povećanja težine ili ograničavanja udobnosti korisnika. Upravo štampana rešenja koja nude nove mogućnosti dizajna omogućavaju brzo uvođenje inovativnih proizvoda na tržište.

Primeri industrijskih i potrošačkih rešenja

Štampana elektronika se koristi i u raznim industrijskim rešenjima, kao što su senzori za detekciju curenja, kontrolni moduli u sistemima automatizacije ili inteligentne proizvodne etikete.

U potrošačkom sektoru, primeri uključuju pametne narukvice, fleksibilne displeje, moderne kućne aparate ili inovativne elektronske gadžete. Ovako široka primena dokazuje da štampana elektronika nije samo tehnologija budućnosti, već danas realno podržava razvoj modernih elektronskih sistema u mnogim oblastima.

Prednosti štampane elektronike

Niski troškovi proizvodnje i brže prototipovanje

Jedna od najvećih prednosti štampane elektronike je mogućnost smanjenja troškova proizvodnje. Zahvaljujući preciznim procesima štampe, poput sito štampe ili aditivnih metoda, količina korišćenog provodnog materijala je minimalna, a višak se može prikupiti i ponovo upotrebiti.

Pored toga, štampana elektronika omogućava brže prototipovanje, što olakšava trenutno testiranje novih rešenja, ubrzava razvoj proizvoda i skraćuje vreme plasiranja inovativnih uređaja na tržište.

Preciznost štampe i fleksibilnost kola

Procesi koji se koriste u štampanoj elektronici omogućavaju kreiranje kola sa veoma visokom preciznošću. Zahvaljujući tome, mogu se proizvoditi fleksibilna štampana kola koja se mogu prilagoditi zakrivljenim površinama, tankim materijalima i kompaktnim modulima.

Fleksibilnost kola ih čini otpornijim na mehanička oštećenja i lakšim za integraciju u IoT uređaje, pametnu odeću ili medicinske senzore.

Raznovrsne funkcije: senzori, membrane, upravljački uređaji

Štampana elektronika omogućava implementaciju raznovrsnih funkcija unutar jednog modula. Mogu se kreirati senzori, dodirne membrane, kontrolni elementi ili minijaturne matrične elektrode.

Ove mogućnosti otvaraju vrata dizajnu modernih, kompaktnih i efikasnih uređaja koji bi ranije zahtevali brojne tradicionalne komponente, a sada mogu biti integrisani u jedno fleksibilno štampano kolo.

Štampana elektronika omogućava kreiranje inovativnih proizvoda

Najveća korist od štampane elektronike je njen inovativni potencijal. Ova tehnologija omogućava kreiranje proizvoda koje je ranije bilo teško ili nemoguće realizovati tradicionalnim metodama montaže.

Kompanije poput Dacpol-a koriste štampanu elektroniku kako bi klijentima ponudile fleksibilna, laka i funkcionalna rešenja koja povećavaju konkurentnost i omogućavaju realizaciju specifičnih projekata u medicinskom, automobilskom, IoT i kućnom sektoru.

Uticaj proizvodnje na životnu sredinu i ekologija

Aditivni procesi i ograničavanje otpada

Štampana elektronika koristi aditivne procese, gde se provodni materijal nanosi samo tamo gde je potreban. Kao rezultat toga, količina proizvodnog otpada je minimalna, a svaki element procesa se koristi efikasno.

Kod tradicionalnih metoda proizvodnje elektronike stvara se mnogo više otpada, što generiše dodatne troškove i opterećuje životnu sredinu. U štampanoj elektronici, višak materijala se može vratiti u proces, a sama proizvodnja je ekološki prihvatljivija i održivija.

Održive tehnologije štampe i reciklaža viška materijala

U kompanijama kao što je Dacpol primenjuju se održive tehnologije štampe koje omogućavaju minimiziranje negativnog uticaja proizvodnje na životnu sredinu. Višak provodnih materijala, poput srebrnih mastila ili provodnih boja, sakuplja se i ponovo koristi.

Takav pristup omogućava ne samo smanjenje troškova, već i odgovara na sve veće ekološke zahteve klijenata i standarde industrijske proizvodnje.

Zahvaljujući preciznoj štampi: minimiziranje negativnog uticaja na sredinu

Metode visoke preciznosti koje se koriste u štampanoj elektronici osiguravaju pravilno nanošenje materijala i smanjenje gubitaka. Zahvaljujući preciznoj štampi, proizvodni proces je čistiji, a emisije otpada i hemikalija svedene su na minimum.

Na taj način štampana elektronika omogućava kreiranje inovativnih, fleksibilnih i funkcionalnih elektronskih kola, uz istovremenu brigu o životnoj sredini i podršku održivom razvoju u elektronskoj industriji.

Tržište i budućnost štampane elektronike

Sve veća popularnost štampane elektronike i tržišne prognoze

Štampana elektronika stiče sve veću popularnost na svetskom tržištu. Sve više kompanija investira u fleksibilna štampana kola i savremene provodne materijale kako bi kreirali inovativne proizvode za medicinu, auto-industriju, IoT ili potrošačku elektroniku.

Tržišne prognoze ukazuju na dinamičan rast segmenta štampane elektronike u narednim godinama, što potvrđuje trend sve veće popularnosti štampane elektronike i njenog rastućeg značaja u strategijama razvoja kompanija širom sveta.

Nove mogućnosti integracije elektronskih sistema

Štampana elektronika obezbeđuje laku integraciju elektronskih sistema, nudeći mogućnost povezivanja senzora, displeja, kontrolnih modula i drugih komponenti u kompaktna i funkcionalna kola.

Ova rešenja podržavaju razvoj IoT-a, pametne odeće i industrijskih uređaja, a takođe omogućavaju dizajn sistema neobičnih oblika koje je ranije bilo teško realizovati tradicionalnim metodama montaže.

Pejzaž štampane elektronike u elektronskoj industriji

Tržište štampane elektronike postaje sve konkurentnije i inovativnije. Kompanije koje investiraju u tehnologije štampe i fleksibilne podloge mogu klijentima ponuditi rešenja prilagođena individualnim potrebama, povećavajući svoju konkurentsku prednost.

DACPOL, oslanjajući se na svoje iskustvo u proizvodnji fleksibilnih štampanih kola, isporučuje rešenja koja kombinuju modernu tehnologiju sa praktičnom primenom u mnogim oblastima – od medicine, preko industrije, do potrošačkih uređaja.

Trendovi u proizvodnji inovativnih uređaja i fleksibilnih kola

U narednim godinama, štampana elektronika će se dalje razvijati u pravcu:

-

kreiranja inovativnih, minijaturnih i fleksibilnih kola,

-

integracije u IoT sisteme i inteligentne uređaje,

-

korišćenja naprednih provodnih materijala i biokompatibilnih kompozita,

-

održivije i ekološki prihvatljivije proizvodnje.

Ovi trendovi dokazuju da štampana elektronika ne samo da dobija na popularnosti, već trasira pravac razvoja moderne elektronske industrije, omogućavajući kreiranje inovativnih proizvoda za širok krug potrošača.

Ponuda kompanije DACPOL u oblasti štampane elektronike

Proizvodi i komponente štampane elektronike dostupni u DACPOL-u

DACPOL nudi širok spektar proizvoda i komponenti štampane elektronike, koji uključuje fleksibilna štampana kola, minijaturne matrične elektrode, senzore i kontrolne elemente. Svi proizvodi se odlikuju visokom preciznošću izrade, izdržljivošću i mogućnošću integracije u savremene elektronske sisteme.

Zahvaljujući upotrebi najkvalitetnijih provodnih materijala, poput srebrnih mastila ili specijalizovanih provodnih boja, proizvodi DACPOL-a su ne samo funkcionalni, već i pouzdani pri dugotrajnoj upotrebi.

Rešenja prilagođena potrebama klijenata i integracija štampane elektronike sa uređajima

Kompanija DACPOL isporučuje rešenja prilagođena individualnim potrebama klijenata, omogućavajući integraciju fleksibilnih štampanih kola sa industrijskim uređajima, IoT sistemima, pametnom odećom ili medicinskom opremom.

Zahvaljujući fleksibilnim rešenjima DACPOL-a, klijenti mogu realizovati inovativne projekte brže i efikasnije, koristeći gotove komponente ili module pripremljene specifično prema njihovim zahtevima.

Fleksibilna štampana kola i specijalizovani materijali

DACPOL se specijalizuje za proizvodnju fleksibilnih štampanih kola izrađenih na PET i polimernim podlogama, uz korišćenje provodnih materijala i biokompatibilnih kompozita.

Fleksibilna rešenja omogućavaju integraciju štampane elektronike u specifične oblike, kao što su zakrivljene površine, pametna odeća, dijagnostički uređaji ili IoT sistemi, proširujući dizajnerske mogućnosti i funkcionalnost krajnjih proizvoda.

Zašto izabrati DACPOL za tehnološkog partnera

Izborom DACPOL-a za tehnološkog partnera, klijenti dobijaju pristup iskustvu, inovativnim tehnologijama i širokom asortimanu proizvoda u oblasti štampane elektronike.

Kompanija nudi podršku u dizajnu, prototipovanju i proizvodnji rešenja prilagođenih potrebama tržišta, što omogućava kreiranje inovativnih, fleksibilnih i pouzdanih proizvoda u mnogim industrijama – od medicine i IoT-a do automobilske industrije, kućnih aparata i opšte industrije.

DACPOL kombinuje visok kvalitet izrade, preciznost štampe i moderne materijale, pružajući svojim klijentima mogućnost da u potpunosti iskoriste potencijal štampane elektronike u svojim projektima.

Rezime i kontakt

Ključne prednosti štampane elektronike

Štampana elektronika (PE) je inovativna tehnologija koja omogućava kreiranje fleksibilnih, lakih i funkcionalnih elektronskih kola. Zahvaljujući preciznim metodama štampe, poput sito štampe ili aditivnih tehnologija, može se postići visoka preciznost, pouzdanost i fleksibilnost kola uz istovremeno smanjenje troškova proizvodnje i minimiziranje otpada.

Ova tehnologija omogućava proizvodnju kola sa različitim funkcijama – od senzora i membrana do minijaturnih matričnih elektroda – i nalazi primenu u mnogim oblastima: medicini, auto-industriji, IoT-u, kućnim aparatima ili industrijskoj elektronici.

Vrednost sadržaja i inovativne mogućnosti

Štampana elektronika pruža mogućnost kreiranja inovativnih proizvoda koje je ranije bilo teško ili nemoguće realizovati tradicionalnim metodama. Visoka preciznost štampe, upotreba savremenih provodnih materijala i fleksibilnih podloga, kao i integracija sa IoT sistemima, otvaraju nove dizajnerske horizonte kompanijama i inženjerima.

DACPOL koristi ove tehnologije za pružanje rešenja prilagođenih individualnim potrebama klijenata, podržavajući razvoj proizvoda, prototipovanje i integraciju u savremene uređaje.

Poziv na kontakt i saradnju

Ako želite da uvedete inovativna rešenja štampane elektronike u svoj projekat ili povećate konkurentnost svojih proizvoda, kontaktirajte DACPOL.

Naš tim stručnjaka pomoći će vam u izboru materijala, dizajnu fleksibilnih štampanih kola i implementaciji rešenja prilagođenih vašim potrebama. Kontaktirajte nas već danas i otkrijte pun potencijal štampane elektronike u praksi!

Leave a comment