Musisz być zalogowany/a

Category

Zdjęcia mają charakter wyłacznie informacyjny. Zobacz specyfikację produktu

please use latin characters

The anti-extrusion rings, also known as back-up rings are used in dynamic or static sealing rods or pistons applications. Under high pressures they prevent the penetration (gap extrusion) of the sealing element (O-Ring or X-Ring) in the sealing gap.

In addition to improving the lifetime of an O-ring or a X-ring by protecting them from any impurities, the use of anti-extrusion rings widens their range of applications while remaining very cost effective in the following cases:

There are 3 standard profiles of back-up rings (BAE):

The profiles AEM and AEC are available in slotted design with an angle of 30 or 45°, or special version (20°) upon request.

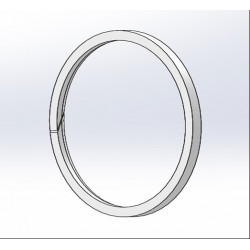

Back-up ring type AES

Back-up ring type AEM

Back-up ring type AEC

The recommendations are identical to those of the installation of the O-ring, however for the non cut back-up rings, the installation in closed grooves should be made with a special tool. The ring must be expanded with a cone and recalibrated after assembly.

| Base material | Type | Pressure | ||

|---|---|---|---|---|

| AES | AEM/F | AEC/F | Bars | |

| PTFE (Virgin) standard | X | X | X | 250 |

| PTFE Glassfibre-filled | X | X | 400 | |

| PTFE Carbon-filled | X | X | 400 | |

| PTFE Bronze-filled | X | 400 | ||

| NBR 90 SH | X | X | 200 | |

| FPM 90 SH | X | X | 200 | |

Jesteś zainteresowany tym produktem? Potrzebujesz dodatkowych informacji lub indywidualnej wyceny?

Musisz być zalogowany/a

The anti-extrusion rings, also known as back-up rings are used in dynamic or static sealing rods or pistons applications. Under high pressures they prevent the penetration (gap extrusion) of the sealing element (O-Ring or X-Ring) in the sealing gap.

In addition to improving the lifetime of an O-ring or a X-ring by protecting them from any impurities, the use of anti-extrusion rings widens their range of applications while remaining very cost effective in the following cases:

There are 3 standard profiles of back-up rings (BAE):

The profiles AEM and AEC are available in slotted design with an angle of 30 or 45°, or special version (20°) upon request.

Back-up ring type AES

Back-up ring type AEM

Back-up ring type AEC

The recommendations are identical to those of the installation of the O-ring, however for the non cut back-up rings, the installation in closed grooves should be made with a special tool. The ring must be expanded with a cone and recalibrated after assembly.

| Base material | Type | Pressure | ||

|---|---|---|---|---|

| AES | AEM/F | AEC/F | Bars | |

| PTFE (Virgin) standard | X | X | X | 250 |

| PTFE Glassfibre-filled | X | X | 400 | |

| PTFE Carbon-filled | X | X | 400 | |

| PTFE Bronze-filled | X | 400 | ||

| NBR 90 SH | X | X | 200 | |

| FPM 90 SH | X | X | 200 | |

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent