Jūs turite būti prisijungę

Category

Nuotraukos yra skirtos tik informaciniams tikslams. Peržiūrėkite produkto specifikaciją

please use latin characters

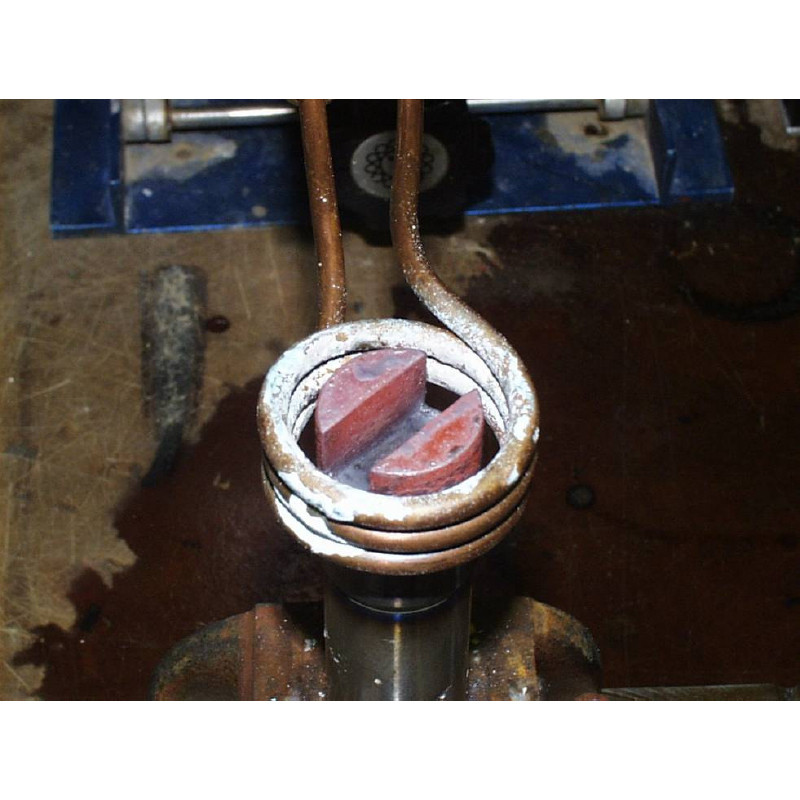

Objective: Annealing the end of a steel hydraulic motor shaft prior to machining.

Frequency: 259 kHz

Material: 0.75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the end.

Temperature: 1350 °F (732 °C)

A three turn helical coil is used for annealing the motor shaft. The end of the motor shaft is placed in the coil and power is applied for 20 seconds to reach 1350 ºF (732 ºC) and turn the steel red hot.

Ar Jūs domina šis produktas? Ar Jums reikia papildomos informacijos ar individualaus pasiūlymo?

tu turi būti prisijungęs

Objective: Annealing the end of a steel hydraulic motor shaft prior to machining.

Frequency: 259 kHz

Material: 0.75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the end.

Temperature: 1350 °F (732 °C)

A three turn helical coil is used for annealing the motor shaft. The end of the motor shaft is placed in the coil and power is applied for 20 seconds to reach 1350 ºF (732 ºC) and turn the steel red hot.

Jūsų atsiliepimo įvertinimas negali būti išsiųstas

Pranešti apie komentarą

Pranešimas apie atsiliepimą išsiųstas

Jūsų pranešimas apie atsiliepimą neišsiųstas

Parašyti savo atsiliepimą

Atsiliepimas išsiųstas

Jūsų atsiliepimas neišsiųstas