Sie müssen eingeloggt sein

Category

Fotos dienen nur zu Informationszwecken.

please use latin characters

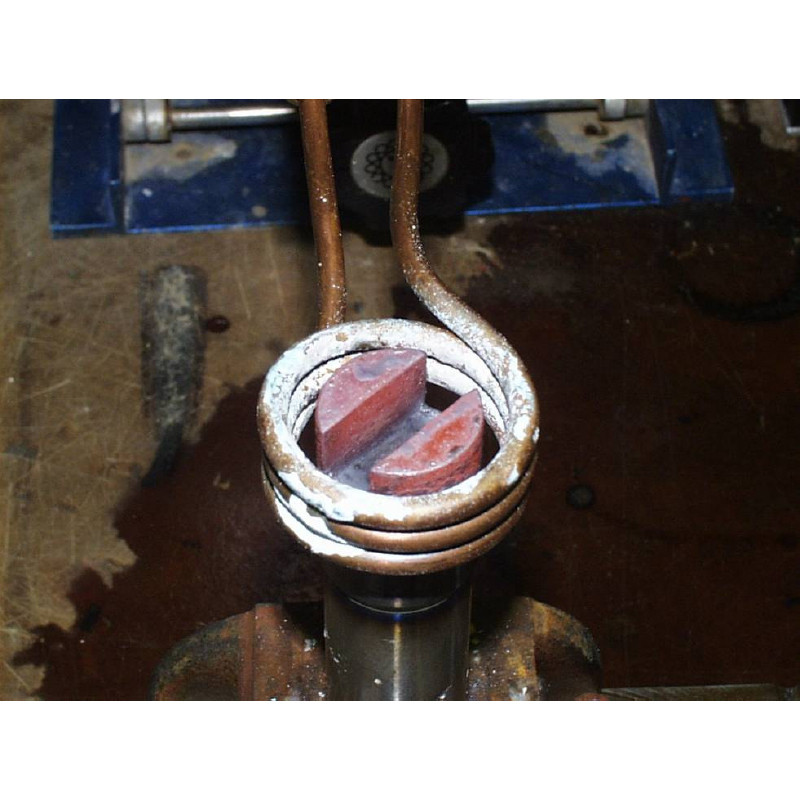

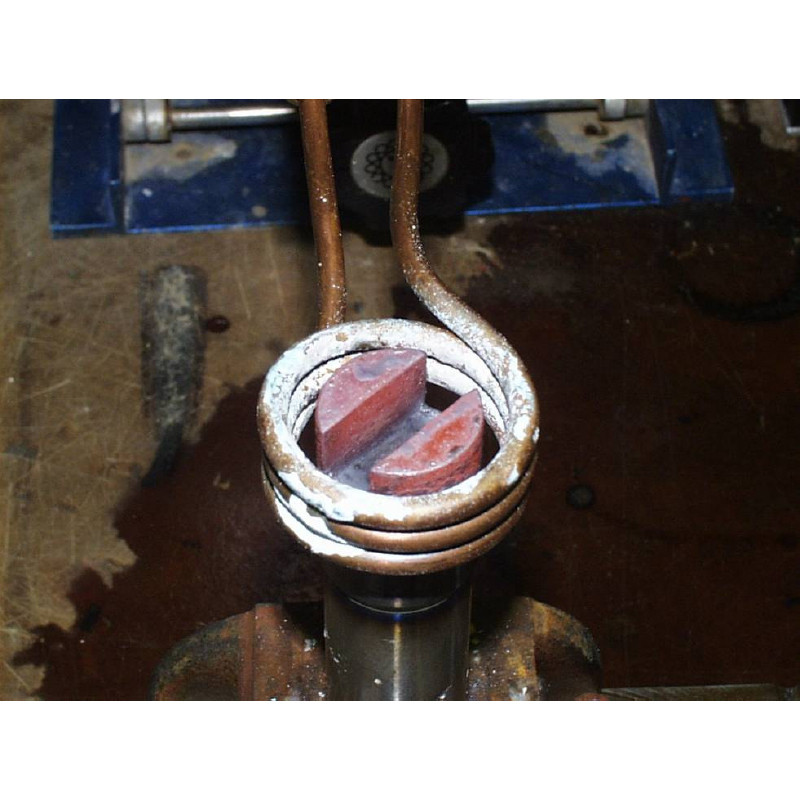

Objective: Annealing the end of a steel hydraulic motor shaft prior to machining.

Frequency: 259 kHz

Material: 0.75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the end.

Temperature: 1350 °F (732 °C)

A three turn helical coil is used for annealing the motor shaft. The end of the motor shaft is placed in the coil and power is applied for 20 seconds to reach 1350 ºF (732 ºC) and turn the steel red hot.

Interessieren Sie sich für dieses Produkt? Benötigen Sie zusätzliche Informationen oder individuelle Preise?

Sie müssen eingeloggt sein

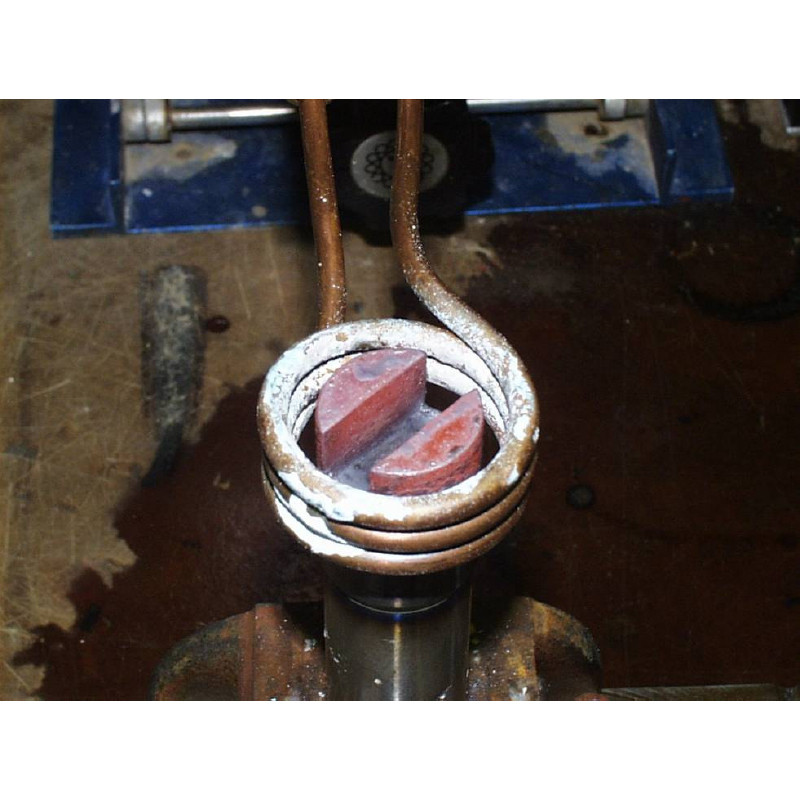

Objective: Annealing the end of a steel hydraulic motor shaft prior to machining.

Frequency: 259 kHz

Material: 0.75” (19mm) diameter steel rod, 6” (152.4mm) long with a keyway at the end.

Temperature: 1350 °F (732 °C)

A three turn helical coil is used for annealing the motor shaft. The end of the motor shaft is placed in the coil and power is applied for 20 seconds to reach 1350 ºF (732 ºC) and turn the steel red hot.

Ihre Bewertung der Rezension kann nicht gesendet werden

Kommentar melden

Meldung gesendet

Ihre Meldung kann nicht gesendet werden

Eigenen Kommentar verfassen

Bewertung gesendet

Ihre Bewertung kann nicht gesendet werden