Sie müssen eingeloggt sein

Category

Fotos dienen nur zu Informationszwecken.

please use latin characters

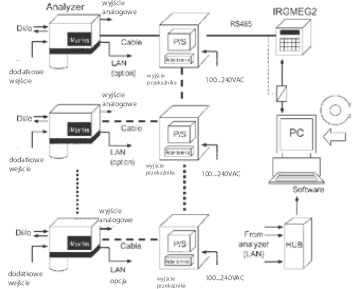

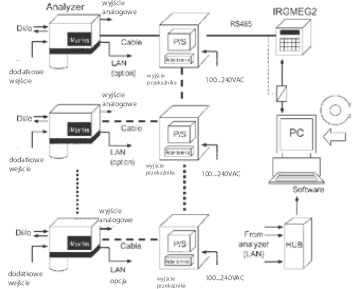

The IM series is an on-line multi IR wavelength Mirror type analyzer utilizing the infrared absorption technology for measuring product constituent and/or thickness. Signal processing capabilities are built into the Compact All-In-One detector unit for easy installation and operation. A maximum of 99 calibration curves can be stored into the detector memory for numerous measurement applications. The detector can be used by itself or connected to a PC/plant control system, as both analog and digital outputs are provided. A remote setting display unit, connectable up to 9 detector units, can be used to setup various detector functions and also displays measured values.

Application:

• Measuring moisture of wood chip.

• Measuring the thickness of sheet or film.

• Measuring the organism, moisture and lipid of fodder.

• Measuring the organism, moisture and oil of potato chips.

• Measuring moisture of garbage (RDF moisture).

• Measuring the coating thickness on the painting sheet.

• Measuring moisture of powder.

• Measuring moisture in cleaning solution.

• Measuring moisture of clay.

• Measuring moisture of fiber.

• Measure [&] Control the coating thickness

of Laminate-sheet production line.

• Measure [&] Control the painting thickness.

Features:

• Up to 10 wavelengths, capable of measuring 4 constituents such as; moisture, film-thickness, organism, and coating-thickness in real time simultaneously.

• Connectivity to multiple interfaces, RS485 (MODBUS), Ethernet (LAN)

• High-speed [&] High-repeatability (28ms)

• Multi-calculation function

• Self-diagnostic function, easy maintenance.

• Conforms to CE standards and IP-65

| Object | Range | Accu. |

|---|---|---|

| General moisture (%) | ||

| Glass / pottery / cement | ||

| Potter's clay | 0...12 | >±0.3 |

| Iron / metal | ||

| Coal | 0...15 | >±0.2 |

| Mix raw material | 0...10 | >±0.2 |

| Iron oxide | 0...10 | >±0.2 |

| Foods | ||

| Starch | 0...25 | >±0.2 |

| Bread-crumbs | 0...20 | >±0.2 |

| Soybean | 0...15 | >±0.2 |

| Milk powder | 0...5 | >±0.2 |

| Sugar / salt | 0...2 | >±0.05 |

| Flavouring | 0...10 | >±0.2 |

| Tea | 0...15 | >±0.2 |

| Chemicals | ||

| Catalyst | 0...10 | >±0.2 |

| Medium | 0...20 | >±0.2 |

| Detergent | 0...15 | >±0.2 |

| Ink | 0...5 | >±0.2 |

| Fertilizer | 0...5 | >±0.2 |

| Rubber / fiber / etc. | ||

| Vinylon fiber | 0...10 | >±0.2 |

| Acrylic fiber | 0...10 | >±0.2 |

| Wood chip | 0...10 | >±0.2 |

| Paper | 0...10 | >±0.1 |

| Material | Range | Accu. |

|---|---|---|

| Wet paper | 40...70 | >±0.5 |

| Raw bread crumbs | 30...40 | >±0.7 |

| Clay | 0...30 | >±0.3 |

| Silica sand | 0...10 | >±0.8 |

| Bicarbonate | 0...18 | >±0.6 |

| Micro moisture | ||

| ABS, PVC powder | 0...1 | >±0.8 |

| Granular ferrite | 0...0.5 | >±0.8 |

| Thickness [um] | ||

| Polyethylene PE | 10...3000 | >+0.2 |

| Polypropylene PP | >±0.2 | |

| Polyester PET | >±0.2 | |

| Vinyl chloride PVC | >±0.2 | |

| PVA | >±0.2 | |

| EVA | >±0.2 | |

| Polystyrene PS | >+0.2 | |

| Polycarbonate | >±0.2 | |

| Nylon PA | >±0.2 | |

| Polyimide PI | >±0.3 | |

| TAC film | >±0.2 | |

| Coating (g/m2) | ||

| Coat-paper | 10...1000 | |

| Tuck-paper, label | ||

| Adhesive WET/DRY | ||

| Resin on steel-board | ||

|

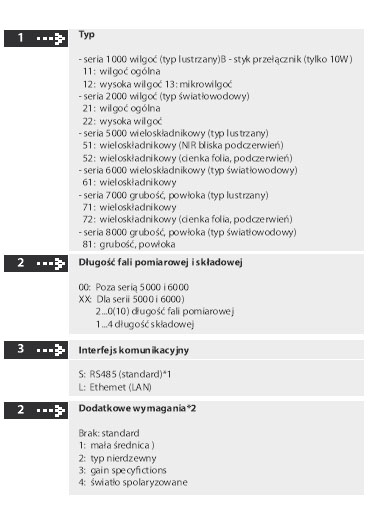

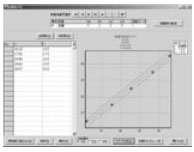

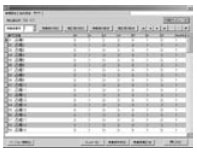

Main Screen Displays measured data, trend and alarm value. Displays 4 constituents on one screen. Save data into specified folder, enable to search or read out the data. |

|

|

|

|

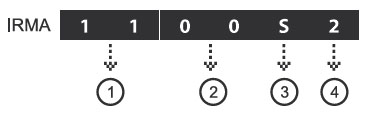

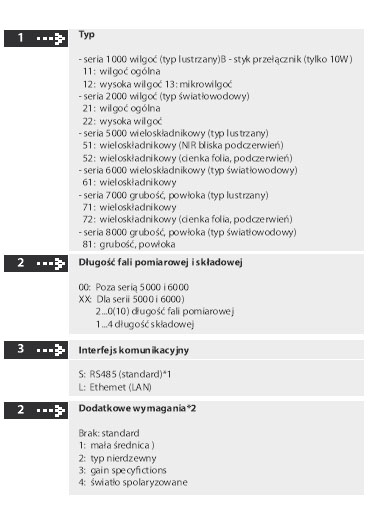

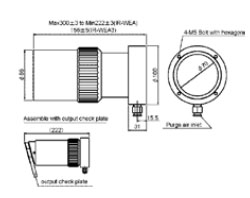

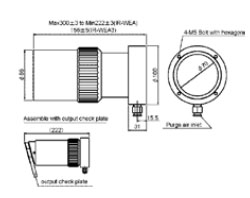

| GENERAL SPECIFICATIONS | |

| INFRARED MULTI ANALYZER | |

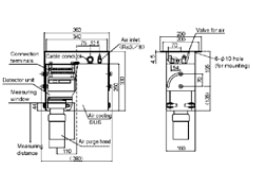

| • Measuring system: | Infrared absorption type |

| • Measuring wavelength: | Up to 10 wavelengths |

| • Measuring component: | Up to 4 constituents |

| • Light source: | Tungsten lamp |

| • Measuring distance: | 200...400 mm (IRMA 1300:160...300 mm) |

| • Measuring diameter: | 50 mm3 / 300 mm (IRMA 1300: 30 mm3/200 mm |

| • Analog output: | 4 to 20mADC, ±0.2% of full scale (Load resistance: less than 500Ω) |

| • Communications:: | RS485 MODBUS |

| • Output renewal cycle: | 28 ms |

| • Display [&] setup: | Displays data [&] setup parameter Parameters are configurable by key. |

| • Computing:: | 2 or 3-color ratio calculation Multiple regression calculation |

| • No. of calibration curve: | Up to 99 curves |

| • Calibration curve: | Linear, quadratic, cubic [&] multiple regression line |

| • Calibration curve correction: | Linear [&] quadratic co |

| • Smoothing (delay): | 0...99 sec |

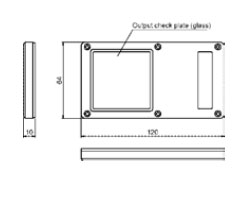

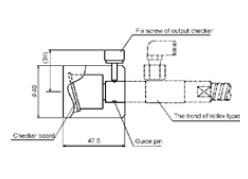

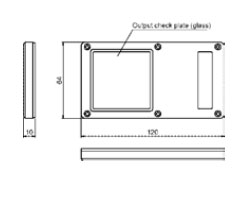

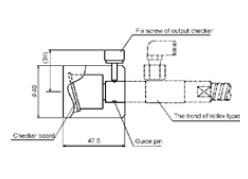

| • Calibration: | By checking plate |

| • Detector No. setup: | When multiple detector operation,detector No. is key configurable. |

| • Channel No. setup: | Calibration curve No. is key configurable. |

| • Self-diagnostic: | Outputs contact signal and communications when abnormal conditions. |

| • Correction input: | Compensate measured value by external 4 to 20mA DC (sample temperature, etc.) |

| • External Di/o: | Di(contact input) --- Perform either oneof preset, data-hold or real/smoothing Do(contact output) --- Selects self-diagnostic(1b) or Hi/low alarm(1a) |

| • Working temperature: | 0 to 50°C (Use dry air cooling if higher than 45°C. Outlet air temperature must be lower than 30°C.) |

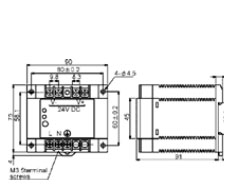

| • Power supply: | 24V DC supplied from IR-WEP (IR-WEP power supply: 100-240VAC) |

| • Power consumption:: | ok. 30 VA |

| • Connection: | terminal |

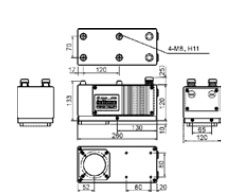

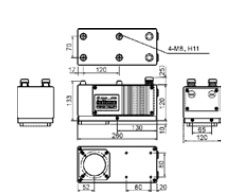

| • Casing: | Aluminum casting, drip-proof structure (conforming to IEC529, IP65) |

| • Weight: | Approx. 4.3kg |

| • Mounting:: | Bolt suspension method with 4 pieces of M8 bolts |

| • CE-standards: | EMC directives EN61326+A |

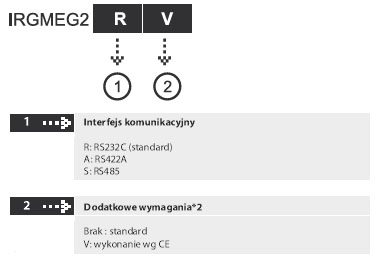

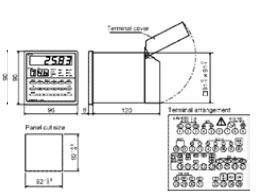

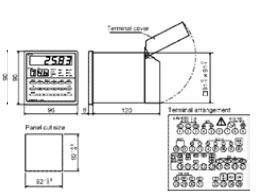

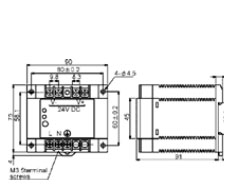

| SETTING DISPLAY UNIT | |

| •Input signal | RS485, Up to 9 detectors connectable |

| • Analog output: | 4 to 20mADC, 2 output* (Load resistance: less than 500Ω) * When multiple detector operation, outputs for detector No. 1 [&] 2. |

| • Communications: | RS232C, RS422 or RS485 |

| • Output renewal cycle:: | 28ms × detector number |

| Display: | 1) Measured data, LED 5-digit |

| 2) Detector No., CH. No., Parameter setup | |

| • Detector No. setup:: | Detector No.1 to No.9 is key configurable. |

| • Calibration curve No. setup | Calibration curve No. is key configurable. |

| • Smoothing time: | T = 0,0...9,9 s, 10...99S |

| • Calibration:: | Perform calibration by key operation or by external contact in use of checking plate |

| • Hold/preset: | Hold or preset the display and output by key operation or external contact. |

| • Calibration curve correction: | Online correction of calibration curve Linear or quadratic correction. |

| • External setup: | Detector No., CH. No., Calibration,Hold or Preset. |

| • Alarm function:: | Outputs contact signal (HCL) beyond setting-range |

| • Self-diagnostic: | Outputs contact signal(1b) when abnormal condition With lamp display |

| • Power supply: | 100...240VAC 50/60 Hz |

| • Power consumption: | max. 15 VA |

| • Working ambient: | 0...50 °C |

| • Casing: | ABS |

| • Protection level | IP65 |

| • Mounting: | Panel-mount type |

| • Weight:: | Approx. 0.6kg |

| CE STANDARDS SPECIFICATIONS | |

| • Analog output:: | 1x4...20mA |

| • Load resistance: | <500n |

| • Power supply:: | 24VDC±10% |

| • Power consumption: | About 10VA |

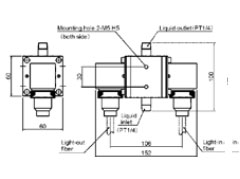

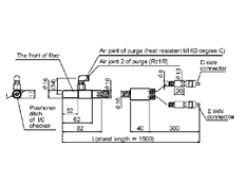

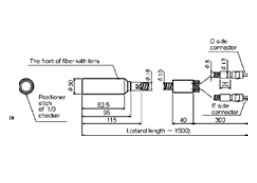

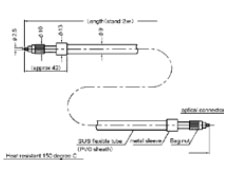

| FIBER UNIT | |

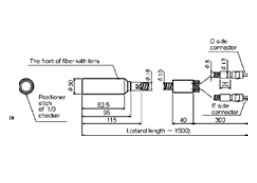

| • Measuring distance and diameter: | With lens --- φ25/25mm to φ40/100mm |

| Without lens --- φ20/15mm to φ50/50mm | |

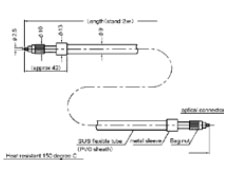

| • Długość światłowodów: | Standard 1.5m, Max.5m (Reflection type fiber) |

| Standard 2m, Max.10m (Transmission type fiber) | |

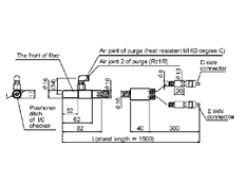

| • Fiber protection: | Stainless steel flexible armour |

| • Minimum bending radius: | r= 100 mm |

| • Working temperature: | 0...150°C |

| • Purge air flow:: | With lens --- Air purge disabled |

| Without lens --- 5 to 20L/min | |

| • Accessory:: | Vertical mounting holder |

| Flange holder | |

|

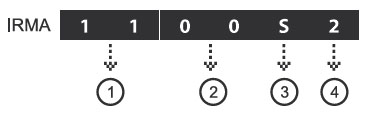

Analyzer IRMA

|

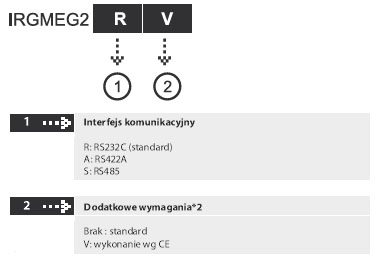

Setting display unit IRGMEG2

|

Power supply unit IR-WEP |

|

Air purge hood IR-WEA

|

Output checking plate IR-WEB

|

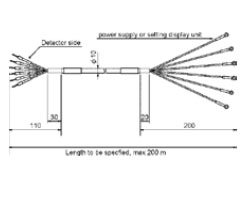

Connecting cable IR-WERP

|

Reflection type fiber |

Reflection type fiber (with lens)

IR-WCRE

|

Transmission type fiber

|

| Output checking plate for reflection type fiber IR-WCRB  |

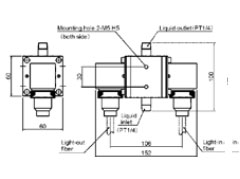

Liquid cell IR-WCC

|

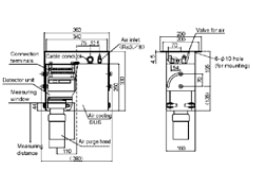

Air-cooling box IR-WEX

|

Interessieren Sie sich für dieses Produkt? Benötigen Sie zusätzliche Informationen oder individuelle Preise?

Sie müssen eingeloggt sein

The IM series is an on-line multi IR wavelength Mirror type analyzer utilizing the infrared absorption technology for measuring product constituent and/or thickness. Signal processing capabilities are built into the Compact All-In-One detector unit for easy installation and operation. A maximum of 99 calibration curves can be stored into the detector memory for numerous measurement applications. The detector can be used by itself or connected to a PC/plant control system, as both analog and digital outputs are provided. A remote setting display unit, connectable up to 9 detector units, can be used to setup various detector functions and also displays measured values.

Application:

• Measuring moisture of wood chip.

• Measuring the thickness of sheet or film.

• Measuring the organism, moisture and lipid of fodder.

• Measuring the organism, moisture and oil of potato chips.

• Measuring moisture of garbage (RDF moisture).

• Measuring the coating thickness on the painting sheet.

• Measuring moisture of powder.

• Measuring moisture in cleaning solution.

• Measuring moisture of clay.

• Measuring moisture of fiber.

• Measure [&] Control the coating thickness

of Laminate-sheet production line.

• Measure [&] Control the painting thickness.

Features:

• Up to 10 wavelengths, capable of measuring 4 constituents such as; moisture, film-thickness, organism, and coating-thickness in real time simultaneously.

• Connectivity to multiple interfaces, RS485 (MODBUS), Ethernet (LAN)

• High-speed [&] High-repeatability (28ms)

• Multi-calculation function

• Self-diagnostic function, easy maintenance.

• Conforms to CE standards and IP-65

| Object | Range | Accu. |

|---|---|---|

| General moisture (%) | ||

| Glass / pottery / cement | ||

| Potter's clay | 0...12 | >±0.3 |

| Iron / metal | ||

| Coal | 0...15 | >±0.2 |

| Mix raw material | 0...10 | >±0.2 |

| Iron oxide | 0...10 | >±0.2 |

| Foods | ||

| Starch | 0...25 | >±0.2 |

| Bread-crumbs | 0...20 | >±0.2 |

| Soybean | 0...15 | >±0.2 |

| Milk powder | 0...5 | >±0.2 |

| Sugar / salt | 0...2 | >±0.05 |

| Flavouring | 0...10 | >±0.2 |

| Tea | 0...15 | >±0.2 |

| Chemicals | ||

| Catalyst | 0...10 | >±0.2 |

| Medium | 0...20 | >±0.2 |

| Detergent | 0...15 | >±0.2 |

| Ink | 0...5 | >±0.2 |

| Fertilizer | 0...5 | >±0.2 |

| Rubber / fiber / etc. | ||

| Vinylon fiber | 0...10 | >±0.2 |

| Acrylic fiber | 0...10 | >±0.2 |

| Wood chip | 0...10 | >±0.2 |

| Paper | 0...10 | >±0.1 |

| Material | Range | Accu. |

|---|---|---|

| Wet paper | 40...70 | >±0.5 |

| Raw bread crumbs | 30...40 | >±0.7 |

| Clay | 0...30 | >±0.3 |

| Silica sand | 0...10 | >±0.8 |

| Bicarbonate | 0...18 | >±0.6 |

| Micro moisture | ||

| ABS, PVC powder | 0...1 | >±0.8 |

| Granular ferrite | 0...0.5 | >±0.8 |

| Thickness [um] | ||

| Polyethylene PE | 10...3000 | >+0.2 |

| Polypropylene PP | >±0.2 | |

| Polyester PET | >±0.2 | |

| Vinyl chloride PVC | >±0.2 | |

| PVA | >±0.2 | |

| EVA | >±0.2 | |

| Polystyrene PS | >+0.2 | |

| Polycarbonate | >±0.2 | |

| Nylon PA | >±0.2 | |

| Polyimide PI | >±0.3 | |

| TAC film | >±0.2 | |

| Coating (g/m2) | ||

| Coat-paper | 10...1000 | |

| Tuck-paper, label | ||

| Adhesive WET/DRY | ||

| Resin on steel-board | ||

|

Main Screen Displays measured data, trend and alarm value. Displays 4 constituents on one screen. Save data into specified folder, enable to search or read out the data. |

|

|

|

|

| GENERAL SPECIFICATIONS | |

| INFRARED MULTI ANALYZER | |

| • Measuring system: | Infrared absorption type |

| • Measuring wavelength: | Up to 10 wavelengths |

| • Measuring component: | Up to 4 constituents |

| • Light source: | Tungsten lamp |

| • Measuring distance: | 200...400 mm (IRMA 1300:160...300 mm) |

| • Measuring diameter: | 50 mm3 / 300 mm (IRMA 1300: 30 mm3/200 mm |

| • Analog output: | 4 to 20mADC, ±0.2% of full scale (Load resistance: less than 500Ω) |

| • Communications:: | RS485 MODBUS |

| • Output renewal cycle: | 28 ms |

| • Display [&] setup: | Displays data [&] setup parameter Parameters are configurable by key. |

| • Computing:: | 2 or 3-color ratio calculation Multiple regression calculation |

| • No. of calibration curve: | Up to 99 curves |

| • Calibration curve: | Linear, quadratic, cubic [&] multiple regression line |

| • Calibration curve correction: | Linear [&] quadratic co |

| • Smoothing (delay): | 0...99 sec |

| • Calibration: | By checking plate |

| • Detector No. setup: | When multiple detector operation,detector No. is key configurable. |

| • Channel No. setup: | Calibration curve No. is key configurable. |

| • Self-diagnostic: | Outputs contact signal and communications when abnormal conditions. |

| • Correction input: | Compensate measured value by external 4 to 20mA DC (sample temperature, etc.) |

| • External Di/o: | Di(contact input) --- Perform either oneof preset, data-hold or real/smoothing Do(contact output) --- Selects self-diagnostic(1b) or Hi/low alarm(1a) |

| • Working temperature: | 0 to 50°C (Use dry air cooling if higher than 45°C. Outlet air temperature must be lower than 30°C.) |

| • Power supply: | 24V DC supplied from IR-WEP (IR-WEP power supply: 100-240VAC) |

| • Power consumption:: | ok. 30 VA |

| • Connection: | terminal |

| • Casing: | Aluminum casting, drip-proof structure (conforming to IEC529, IP65) |

| • Weight: | Approx. 4.3kg |

| • Mounting:: | Bolt suspension method with 4 pieces of M8 bolts |

| • CE-standards: | EMC directives EN61326+A |

| SETTING DISPLAY UNIT | |

| •Input signal | RS485, Up to 9 detectors connectable |

| • Analog output: | 4 to 20mADC, 2 output* (Load resistance: less than 500Ω) * When multiple detector operation, outputs for detector No. 1 [&] 2. |

| • Communications: | RS232C, RS422 or RS485 |

| • Output renewal cycle:: | 28ms × detector number |

| Display: | 1) Measured data, LED 5-digit |

| 2) Detector No., CH. No., Parameter setup | |

| • Detector No. setup:: | Detector No.1 to No.9 is key configurable. |

| • Calibration curve No. setup | Calibration curve No. is key configurable. |

| • Smoothing time: | T = 0,0...9,9 s, 10...99S |

| • Calibration:: | Perform calibration by key operation or by external contact in use of checking plate |

| • Hold/preset: | Hold or preset the display and output by key operation or external contact. |

| • Calibration curve correction: | Online correction of calibration curve Linear or quadratic correction. |

| • External setup: | Detector No., CH. No., Calibration,Hold or Preset. |

| • Alarm function:: | Outputs contact signal (HCL) beyond setting-range |

| • Self-diagnostic: | Outputs contact signal(1b) when abnormal condition With lamp display |

| • Power supply: | 100...240VAC 50/60 Hz |

| • Power consumption: | max. 15 VA |

| • Working ambient: | 0...50 °C |

| • Casing: | ABS |

| • Protection level | IP65 |

| • Mounting: | Panel-mount type |

| • Weight:: | Approx. 0.6kg |

| CE STANDARDS SPECIFICATIONS | |

| • Analog output:: | 1x4...20mA |

| • Load resistance: | <500n |

| • Power supply:: | 24VDC±10% |

| • Power consumption: | About 10VA |

| FIBER UNIT | |

| • Measuring distance and diameter: | With lens --- φ25/25mm to φ40/100mm |

| Without lens --- φ20/15mm to φ50/50mm | |

| • Długość światłowodów: | Standard 1.5m, Max.5m (Reflection type fiber) |

| Standard 2m, Max.10m (Transmission type fiber) | |

| • Fiber protection: | Stainless steel flexible armour |

| • Minimum bending radius: | r= 100 mm |

| • Working temperature: | 0...150°C |

| • Purge air flow:: | With lens --- Air purge disabled |

| Without lens --- 5 to 20L/min | |

| • Accessory:: | Vertical mounting holder |

| Flange holder | |

|

Analyzer IRMA

|

Setting display unit IRGMEG2

|

Power supply unit IR-WEP |

|

Air purge hood IR-WEA

|

Output checking plate IR-WEB

|

Connecting cable IR-WERP

|

Reflection type fiber |

Reflection type fiber (with lens)

IR-WCRE

|

Transmission type fiber

|

| Output checking plate for reflection type fiber IR-WCRB  |

Liquid cell IR-WCC

|

Air-cooling box IR-WEX

|

Ihre Bewertung der Rezension kann nicht gesendet werden

Kommentar melden

Meldung gesendet

Ihre Meldung kann nicht gesendet werden

Eigenen Kommentar verfassen

Bewertung gesendet

Ihre Bewertung kann nicht gesendet werden