Jūs turite būti prisijungę

Category

Nuotraukos yra skirtos tik informaciniams tikslams. Peržiūrėkite produkto specifikaciją

please use latin characters

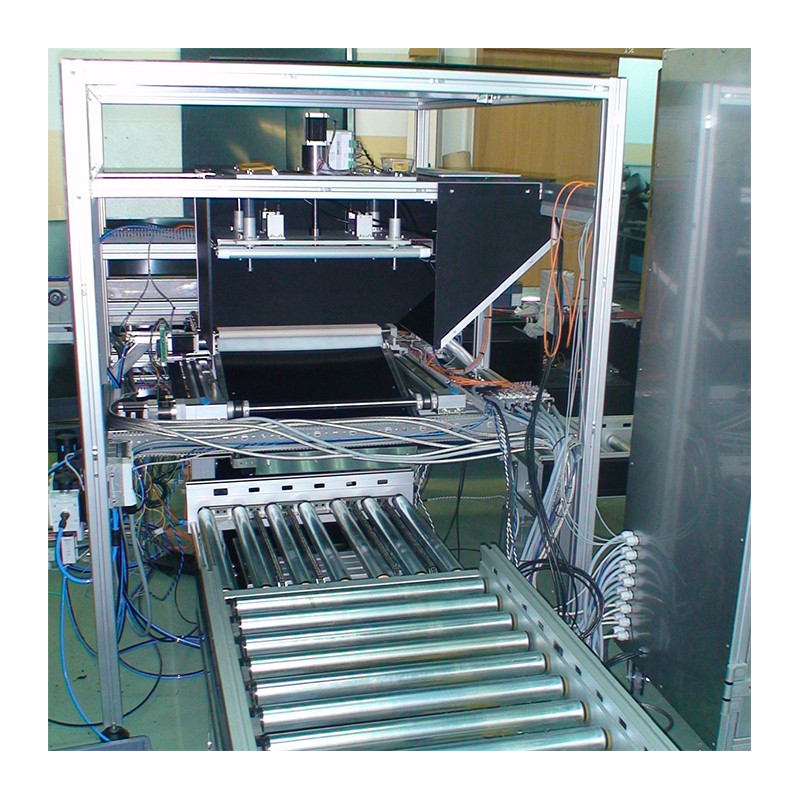

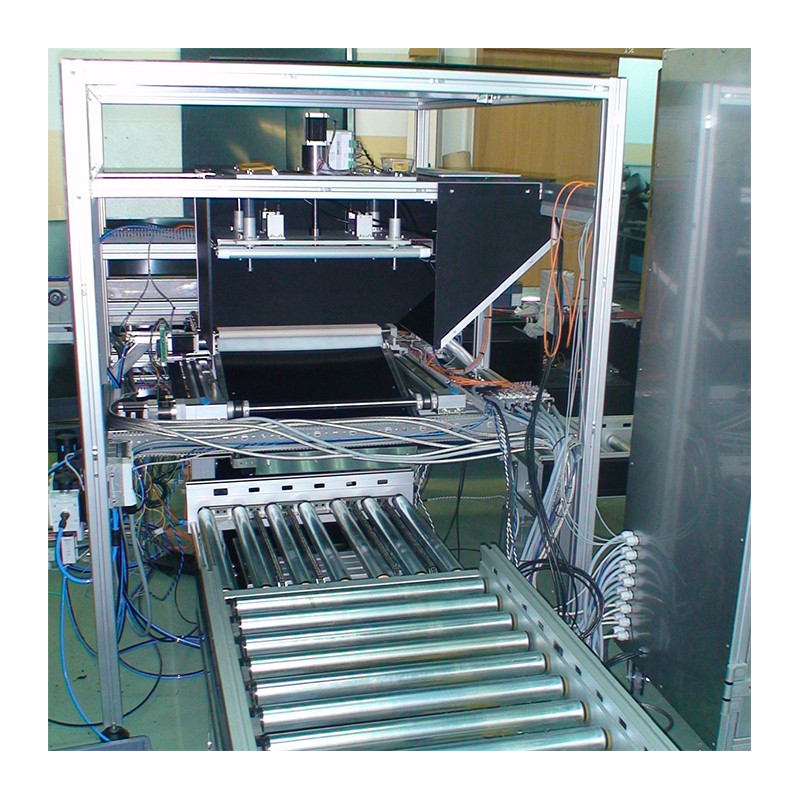

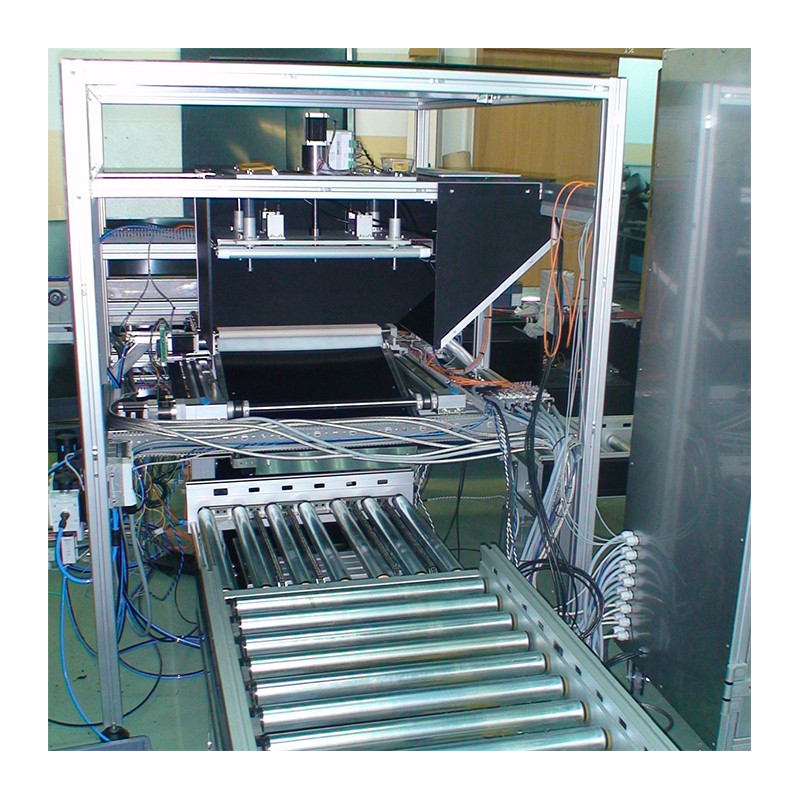

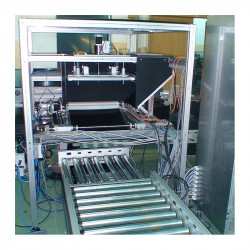

Stotelė skirta įvairių matmenų kartonų ženklinimui - vienintelis apribojimas yra kartono plotis, kuris negali viršyti 500 mm. Kiekviename kartone yra klijuojamos 2 etiketės ant gretimų pusių - etiketės gaunamos internetu iš kliento duomenų bazės.

Įrenginys sujungia spausdinimo ir etikečių taikymo funkcijas ant kartonų, judančių ant konvejerio. Kartonai ant konvejerio yra dedami rankiniu būdu ir pašalinami rankiniu būdu. Įėjime ir išėjime įrenginys turi 2 nepriklausomus keltuvus, skirtus kartonų paletėms kelti ir nuleisti, padedant operatoriui. Įrenginys automatiškai išskiria kartonus ant juostos, kad būtų užtikrintas sklandus ženklinimas.

Etikečių aplikatorius veikia kaip savarankiška etikečių taikymo stotelė, kurioje etikečių spausdinimas paleidžiamas nuskaitymo kartono brūkšninį kodą (gamybos etiketę). Atspausdintos etiketės sistemoje yra pažymimos ir blokuojamos nuo pakartotinio automatinio spausdinimo, tačiau operatorius turi galimybę jas pakartotinai spausdinti rankiniu būdu papildomame spausdintuve, skirtame masinėms etiketėms. Pažymėti kartonai patenka į ritininį konvejerį, kurį ištuština operatorius.

Ar Jūs domina šis produktas? Ar Jums reikia papildomos informacijos ar individualaus pasiūlymo?

tu turi būti prisijungęs

Stotelė skirta įvairių matmenų kartonų ženklinimui - vienintelis apribojimas yra kartono plotis, kuris negali viršyti 500 mm. Kiekviename kartone yra klijuojamos 2 etiketės ant gretimų pusių - etiketės gaunamos internetu iš kliento duomenų bazės.

Įrenginys sujungia spausdinimo ir etikečių taikymo funkcijas ant kartonų, judančių ant konvejerio. Kartonai ant konvejerio yra dedami rankiniu būdu ir pašalinami rankiniu būdu. Įėjime ir išėjime įrenginys turi 2 nepriklausomus keltuvus, skirtus kartonų paletėms kelti ir nuleisti, padedant operatoriui. Įrenginys automatiškai išskiria kartonus ant juostos, kad būtų užtikrintas sklandus ženklinimas.

Etikečių aplikatorius veikia kaip savarankiška etikečių taikymo stotelė, kurioje etikečių spausdinimas paleidžiamas nuskaitymo kartono brūkšninį kodą (gamybos etiketę). Atspausdintos etiketės sistemoje yra pažymimos ir blokuojamos nuo pakartotinio automatinio spausdinimo, tačiau operatorius turi galimybę jas pakartotinai spausdinti rankiniu būdu papildomame spausdintuve, skirtame masinėms etiketėms. Pažymėti kartonai patenka į ritininį konvejerį, kurį ištuština operatorius.

Jūsų atsiliepimo įvertinimas negali būti išsiųstas

Pranešti apie komentarą

Pranešimas apie atsiliepimą išsiųstas

Jūsų pranešimas apie atsiliepimą neišsiųstas

Parašyti savo atsiliepimą

Atsiliepimas išsiųstas

Jūsų atsiliepimas neišsiųstas