Jūs turite būti prisijungę

-

sugrįžtiX

-

Komponentai

-

-

Category

-

Puslaidininkiai

- Diodai

- Tiristoriai

-

Elektroizoliuoti moduliai

- Elektrai izoliuoti moduliai | VISHAY (IR)

- Elektrai izoliuoti moduliai | INFINEON (EUPEC)

- Elektrai izoliuoti moduliai | Semikronas

- Elektrai izoliuoti moduliai | POWEREX

- Elektrai izoliuoti moduliai | IXYS

- Elektrai izoliuoti moduliai | POSEICO

- Elektrai izoliuoti moduliai | ABB

- Elektrai izoliuoti moduliai | TECHSEM

- Eikite į subkategoriją

- Lygintuviniai tilteliai

-

Tranzistoriai

- Tranzistoriai | GeneSiC

- SiC MOSFET moduliai | Mitsubishi

- SiC MOSFET moduliai | STARPOWER

- „ABB SiC MOSFET“ moduliai

- IGBT moduliai | MITSUBISHI

- Tranzistorių moduliai | MITSUBISHI

- MOSFET moduliai | MITSUBISHI

- Tranzistorių moduliai | ABB

- IGBT moduliai POWEREX

- IGBT moduliai INFINEON (EUPEC)

- Silicio karbido puslaidininkiniai elementai

- Eikite į subkategoriją

- Valdikliai

- Galios blokai

- Eikite į subkategoriją

- Elektrinių dydžių keitikliai

-

Pasyvūs komponentai (kondensatoriai, rezistoriai, saugikliai, filtrai)

- Rezistoriai

-

Saugikliai

- ABC ir AGC serijos miniatiūriniai saugikliai elektronikai

- Greitaeigiai cilindriniai saugikliai

- Uždelsimo elementai su GL/GG ir AM charakteristikomis

- Ultragreiti intarpai - saugikliai

- Didžiosios Britanijos ir JAV standartų greitaeigiai saugikliai

- Europos standarto greitaeigiai saugikliai

- Saugikliai geležinkeliui

- Aukštos įtampos saugikliai

- Eikite į subkategoriją

-

Kondensatoriai

- Kondensatoriai varikliams

- Elektrolitiniai kondensatoriai

- Snubbers tipo kondensatoriai

- Galios kondensatoriai

- Kondensatoriai DC grandinėms

- Kondensatoriai galios kompensavimui

- Aukštos įtampos kondensatoriai

- Kondensatoriai indukciniam kaitinimui

- Impulsiniai ir energijos kaupimo kondensatoriai

- DC LINK kondensatoriai

- AC / DC grandinių kondensatoriai

- Eikite į subkategoriją

- Slopinimo tinklo filtrai

- Superkondensatoriai

- Apsauga nuo viršįtampių

- TEMPEST spindulių aptikimo filtrai

- Viršįtampių ribotuvas

- Eikite į subkategoriją

-

Relės ir kontaktoriai

- Relių ir kontaktorių teorija

- Trijų fazių puslaidininkinės AC relės

- Puslaidininkinės DC relės

- Reguliatoriai, valdikliai ir jų priedai

- Soft starteriai (minkšto paleidimo įrenginiai) bei reversiniai kontaktoriai

- Elektromechaninės relės

- Kontaktoriai

- Rotaciniai jungikliai

-

Vienos fazės puslaidininkinės AC relės

- AC vienfazės puslaidininkinės relės 1 | D2425 | D2450 serijų

- AC vienfazės puslaidininkinės relės CWA ir CWD serijų

- AC vienfazės puslaidininkinės relės CMRA ir CMRD serijų

- AC vienfazės puslaidininkinės relės PS serijos

- AC puslaidininkinės dvigubos ir keturgubos relės D24 D, TD24 Q, H12D48 D serijų

- Vienfazės puslaidininkinės relės gn serijos

- AC vienfazės puslaidininkinės relės CKR serijos

- AC vienfazės relės DIN bėgiams ERDA ir ERAA serijų

- Vienfazės kintamosios srovės relės, skirtos 150A srovei

- Dvigubos kietojo kūno relės, integruotos su radiatoriumi DIN bėgiui

- Eikite į subkategoriją

- Vienos fazės puslaidininkinės AC relės spausdinimo plokštėms

- Interfejsų relės

- Eikite į subkategoriją

- Indukciniai elementai

- Radiatoriai, varistoriai, termo apsauga

- Ventiliatoriai

- Kondicioneriai, elektros spintų aksesuarai, aušintuvai

-

Baterijos, įkrovikliai, buferiniai maitinimo šaltiniai ir keitikliai

- Baterijos, įkrovikliai - teorinis aprašymas

- Ličio jonų baterijos. Individualios baterijos. Baterijų valdymo sistema (BMS)

- Akumuliatoriai

- Akumuliatorių įkrovikliai ir priedai

- UPS atsarginis maitinimo šaltinis ir buferiniai maitinimo šaltiniai

- Fotoelektros keitikliai ir priedai

- Energijos kaupimas

- Kuro elementai

- Ląstelės litio-joninės

- Eikite į subkategoriją

-

Automatikos komponentai

- Spiralift keltuvai

- Futaba dronų dalys

- Galiniai jungikliai, mikrojungikliai

- Jutikliai, keitikliai

- Pirometrai

- Skaitikliai, laiko relės, paneliniai matuokliai

- Pramoniniai apsaugos įrenginiai

- Šviesos ir garso signalizacija

- Terminio vaizdo kamera

- LED švieslentės

- Valdymo aparatūra - mygtukai ir jungikliai

- Eikite į subkategoriją

-

Laidai, pynės, laidų apsauginės žarnos, lankstūs sujungimai

- Laidai

- Kabelių įvadai ir movos

- Daugiagisliai laidai

-

Kabeliai ekstremalioms sąlygoms

- Kompensaciniai ir prailginimo kabeliai

- Laidai termoporoms

- PT jutikliams prijungimo laidai

- Daugiagysliai laidai temp. -60C iki +1400C

- Vidutinės įtampos kabeliai

- Uždegimo laidai

- Šildymo laidai

- Viengysliai laidai temp. -60C iki +450C

- Geležinkelio kabeliai

- Šildymo kabeliai Ex zonoms

- Eikite į subkategoriją

- Apsaugos vamzdeliai

-

Pintinės

- Plokščios pintinės

- Apvalios pintinės

- Plokščios labai elastingos pintinės

- Apvalios labai elastingos pintinės

- Cilindro formos vario pintinės

- Vario cilindrinės pintinės su apsauga

- Elastingos įžeminimo juostos

- PCV izoliuotos vario pintinės - temperatūra iki 85 C

- Plokščios aliuminio pintinės

- Sujungimo komplektas - pintinės ir vamzdeliai

- Plieno pintinės

- Eikite į subkategoriją

- Aksesuarai geležinkeliams

- Kabelių antgaliai

- Lanksčios izoliuotos šynos

- Daugiasluoksnės lanksčios šynos

- Laidų pravedimo sistemos (PESZLE)

- Eikite į subkategoriją

- Žiūrėti visas kategorijas

-

Puslaidininkiai

-

-

- Tiekėjai

-

Pritaikymų sąrašas

- CNC staklės

- Energetika

- Energy bank

- Indukcinis kaitinimas

- Įranga ir komponentai sprogimo pavojaus zonoms (Ex)

- Kasyklos, metalurgijos ir liejimo pramonė

- Laboratoriniai ir moksliniai matavimai

- Maitinimo šaltiniai (UPS) ir lygintuvinės sistemos

- Medienos džiovinimo ir apdirbimo mašinos

- Nuolatinės ir kintamos srovės pavaros (keitikliai)

- Paskirstymo, valdymo ir telekomunikacijos spintų įranga

- Plastmasių liejimo mašinos

- Poligrafija

- Pramoninė apsaugos įranga

- Pramoninė automatika

- Suvirinimo aparatai

- ŠVOK automatika

- Temperatūros matavimas ir nustatymas

- Tramvajų ir traukinių pavaros

- Varikliai ir transformatoriai

-

Montavimas

-

-

Induktoriai

-

-

Indukciniai įtaisai

-

-

Aptarnavimas

-

- Kontaktai

- Zobacz wszystkie kategorie

Why Invest in Industrial Control Cabinet Air Conditioning? ROI and Extended Component Lifespan

Introduction

In industrial conditions, the reliability of automation systems depends not only on the quality of the components used but also on the environment in which they operate. One of the key factors influencing their durability and stability is the temperature inside control cabinets. Even slight exceedances of acceptable values can lead to unexpected downtime, costly failures, or shortened equipment lifespan.

Why Do Components Need Cooling?

Electronic devices such as inverters, PLCs, power supplies, or communication modules generate heat during normal operation. In the confined space of a control cabinet, this heat accumulates, and if not effectively dissipated, the internal temperature can quickly exceed the permissible limits set by equipment manufacturers.

Here’s what can happen when the cabinet temperature exceeds safe levels:

- Shortened lifespan of electronic components,

- Lower operational reliability – increased susceptibility to system errors and device reboots,

- Increased risk of failures and thermal damage,

- Production downtime costs due to necessary repairs or equipment replacements.

In many cases, passive cooling systems (e.g., natural ventilation) are insufficient, especially in applications operating at elevated ambient temperatures, with high component density, or in dusty environments.

That’s why active cooling systems, such as industrial air conditioners, not only increase installation reliability but also directly reduce operational costs.

ROI – Is Air Conditioning Really Worth It?

Investing in industrial air conditioning for control cabinets may seem expensive at first, but in many cases, it pays off faster than expected. Let’s analyze it through the lens of Return on Investment (ROI).

1. Extended Component Lifespan

Industrial electronics are typically designed to operate at temperatures up to 40–45°C. Exceeding this threshold leads to:

- Degradation of electrolytic capacitors,

- Shortened lifespan of power supplies and inverters,

- Decreased reliability of PLCs.

➡ It’s estimated that every +10°C above nominal temperature shortens device lifespan by 50%. This means that investing in cooling can double the lifecycle of many components.

2. Reduction of Unplanned Downtime

A control cabinet failure can stop the entire production line, and every minute of downtime costs:

- From several to tens of thousands of PLN per hour (depending on the industry),

- Additional hours of maintenance team work,

- Potential material losses and production delays.

➡ Air conditioning prevents overheating and thermal faults – reducing downtime risk.

3. Lower Maintenance Costs

Maintaining the proper temperature extends mean time between failures (MTBF), which means:

- Less frequent part replacements,

- Fewer service interventions,

- Reduced spare parts inventory and logistics costs.

4. Predictability and Monitoring

Modern industrial air conditioners (e.g., nVent SpectraCool) offer:

- Remote monitoring via Modbus/RS485,

- Temperature overrun alarms,

- Temperature trend analysis.

➡ This enables predictive maintenance and planned servicing without surprises.

Conclusion: The cost of purchasing and installing an air conditioner often pays off within 1–2 years, thanks to reduced failures and associated costs.

What to Consider When Choosing a Control Cabinet Air Conditioner?

1. Cooling Capacity (W, BTU/h)

Select the air conditioner based on the calculated thermal load. For example:

- Cabinet in a production hall: approx. 500–1000 W,

- Cabinet in an outdoor container: often over 1000 W.

It’s recommended to add a 15–20% power margin for variable factors such as rising ambient temperature or future component additions.

2. Environmental Conditions

Consider the environment in which the cabinet operates:

- Dust, dirt, oil mist → choose an air conditioner with IP54–IP66,

- High ambient temperatures → required operation range up to 55°C or more,

- Outdoor installations → models resistant to weather, preferably INOX or with anti-corrosion coating.

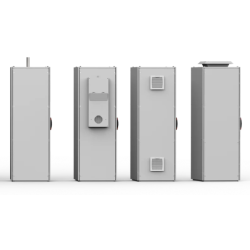

3. Mounting Type

Different mounting variants are available:

- Side-mounted – most popular, easy to service,

- Roof-mounted – saves side cabinet space,

- Internal door-mounted – if the cabinet is placed close to other equipment.

4. Communication and Integration

Modern air conditioners offer integration with SCADA/BMS systems:

- RS485, Modbus, Ethernet interfaces,

- Temperature alarms, compressor control,

- Remote management and diagnostics capabilities.

5. Manufacturer and Service

Choose devices from reputable manufacturers (e.g., nVent), who offer:

- Long-term support,

- Availability of spare parts,

- Selection tools and online calculators.

Summary

Investing in industrial control cabinet air conditioning is not just a cost – it's a way to ensure the continuity of automation and energy systems. Maintaining stable internal cabinet temperature:

- Extends the lifespan of electronic components,

- Minimizes the risk of failures and downtimes,

- Increases the reliability of control systems,

- Reduces service and equipment replacement costs.

With a properly selected cooling system, a high ROI (Return on Investment) is achievable – often within 1–2 years in environments with high dust levels or elevated temperatures.

Modern air conditioners also offer remote monitoring features, SCADA/BMS integration, and IP54–IP66 protection, making them an ideal solution for demanding industrial applications.

Related product

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Leave a comment