-

BackX

-

Components

-

-

Category

-

Semiconductors

- Diodes

- Thyristors

-

Electro-insulated Modules

- Electro-insulated Modules | VISHAY (IR)

- Electro-insulated Modules | INFINEON (EUPEC)

- Electro-insulated Modules | Semikron

- Electro-insulated Modules | POWEREX

- Electro-insulated Modules | IXYS

- Electro-insulated Modules | POSEICO

- Electro-insulated Modules | ABB

- Electro-insulated Modules | TECHSEM

- Go to the subcategory

- Bridge Rectifiers

-

Transistors

- Transistors | GeneSiC

- SiC MOSFET Modules | Mitsubishi

- SiC MOSFET Modules | STARPOWER

- Module SiC MOSFET ABB’s

- IGBT Modules | MITSUBISHI

- Transistor Modules | MITSUBISHI

- MOSFET Modules | MITSUBISHI

- Transistor Modules | ABB

- IGBT Modules | POWEREX

- IGBT Modules | INFINEON (EUPEC)

- Silicon Carbide (SiC) semiconductor elements

- Go to the subcategory

- Gate Drivers

- Power Blocks

- Go to the subcategory

- Electrical Transducers

-

Passive components (capacitors, resistors, fuses, filters)

- Resistors

-

Fuses

- Miniature Fuses for electronic circuits - ABC & AGC Series

- Tubular Fast-acting Fuses

- Time-delay Fuse Links with GL/GG & AM characteristics

- Ultrafast Fuse Links

- Fast-acting Fuses (British & American standard)

- Fast-acting Fuses (European standard)

- Traction Fuses

- High-voltage Fuse Links

- Go to the subcategory

- Capacitors

- EMI Filters

- Supercapacitors

- Power surge protection

- TEMPEST emission revealing filters

- Surge arrester

- Go to the subcategory

-

Relays and Contactors

- Relays and Contactors - Theory

- 3-Phase AC Semiconductor Relays

- DC Semiconductor Relays

- Controllers, Control Systems and Accessories

- Soft Starters and Reversible Relays

- Electromechanical Relays

- Contactors

- Rotary Switches

-

Single-Phase AC Semiconductor Relays

- AC ONE PHASE RELAYS 1 series| D2425 | D2450

- One phase semiconductor AC relays CWA and CWD series

- One phase semiconductor AC relays CMRA and CMRD series

- One phase semiconductor AC relays - PS series

- Double and quadruple semiconductor AC relays - D24 D, TD24 Q, H12D48 D series

- One phase semiconductor relays - gn series

- Ckr series single phase solid state relays

- One phase AC semiconductor relays for DIN bus - ERDA I ERAA series

- 150A AC single phase relays

- Rail Mountable Solid State Relays With Integrated Heat Sink - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Single-Phase AC Semiconductor Relays for PCBs

- Interface Relays

- Go to the subcategory

- Cores and Other Inductive Components

- Heatsinks, Varistors, Thermal Protection

- Fans

- Air Conditioning, Accessories for Electrical Cabinets, Coolers

-

Batteries, Chargers, Buffer Power Supplies and Inverters

- Batteries, Chargers - Theoretical Description

- Modular Li-ion Battery Building Blocks, Custom Batteries, BMS

- Batteries

- Battery Chargers and Accessories

- Uninterruptible Power Supply and Buffer Power Supplies

- Inverters and Photovoltaic Equipments

- Energy storage

- Fuel cells

- Lithium-ion batteries

- Go to the subcategory

-

Automatics

- Spiralift Lifts

- Futaba Drone Parts

- Limit Switches, Microswitches

- Sensors, Transducers

-

Infrared Thermometers (Pyrometers)

- IR-TE Series - Water-proof Palm-sized Radiation Thermometer

- IR-TA Series - Handheld Type Radiation Thermometer

- IR-H Series - Handheld Type Radiation Thermometer

- IR-BA Series - High-speed Compact Radiation Thermometer

- IR-FA Series - Fiber Optic Radiation Thermometer

- IR-BZ Series - Compact Infrared Thermometers

- Go to the subcategory

- Counters, Time Relays, Panel Meters

- Industrial Protection Devices

- Light and Sound Signalling

- Thermographic Camera

- LED Displays

- Control Equipments

- Go to the subcategory

-

Cables, Litz wires, Conduits, Flexible connections

- Wires

- Cable feedthroughs and couplers

- Litz wires

-

Cables for extreme applications

- Extension and Compensation cables

- Thermocouple cables

- Connection cables for PT sensors

- Multi-conductor wires (temp. -60C to +1400C)

- Medium voltage cables

- Ignition wires

- Heating cables

- Single conductor cables (temp. -60C to +450C)

- Railway cables

- Heating cables Ex

- Cables for the defense industry

- Go to the subcategory

- Sleevings

-

Braids

- Flat Braids

- Round Braids

- Very Flexible Flat Braids

- Very Flexible Round Braids

- Cylindrical Cooper Braids

- Cylindrical Cooper Braids and Sleevings

- Flexible Earthing Connections

- PCV Insulated Copper Braids (temp. up to 85C)

- Flat Aluminium Braids

- Junction Set - Braids and Tubes

- Steel Braids

- Go to the subcategory

- Traction Equipment

- Cable Terminals

- Flexible Insulated Busbars

- Flexible Multilayer Busbars

- Cable Duct Systems

- Go to the subcategory

- View all categories

-

Semiconductors

-

-

- Suppliers

-

Applications

- CNC Machine Tools

- DC and AC Drives (Inverters)

- Energetics

- Energy bank

- Equipment and Components for Hazardous Areas [Ex]

- Equipment for Distribution, Control and Telecommunications Cabinets

- HVAC Automation

- Induction Heating

- Industrial Automation

- Industrial Protective Devices

- Machines for Drying and Wood Processing

- Machines for Thermoforming Plastics

- Mining, Metallurgy and Foundry

- Motors and Transformers

- Power Supplies (UPS) and Rectifier Systems

- Printing

- Temperature Measurement and Regulation

- Test and Laboratory Measurements

- Tram and Railway Traction

- Welding Machines

-

Assembly

-

-

Inductors

-

-

Induction devices

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Why Invest in Industrial Control Cabinet Air Conditioning? ROI and Extended Component Lifespan

Introduction

In industrial conditions, the reliability of automation systems depends not only on the quality of the components used but also on the environment in which they operate. One of the key factors influencing their durability and stability is the temperature inside control cabinets. Even slight exceedances of acceptable values can lead to unexpected downtime, costly failures, or shortened equipment lifespan.

Why Do Components Need Cooling?

Electronic devices such as inverters, PLCs, power supplies, or communication modules generate heat during normal operation. In the confined space of a control cabinet, this heat accumulates, and if not effectively dissipated, the internal temperature can quickly exceed the permissible limits set by equipment manufacturers.

Here’s what can happen when the cabinet temperature exceeds safe levels:

- Shortened lifespan of electronic components,

- Lower operational reliability – increased susceptibility to system errors and device reboots,

- Increased risk of failures and thermal damage,

- Production downtime costs due to necessary repairs or equipment replacements.

In many cases, passive cooling systems (e.g., natural ventilation) are insufficient, especially in applications operating at elevated ambient temperatures, with high component density, or in dusty environments.

That’s why active cooling systems, such as industrial air conditioners, not only increase installation reliability but also directly reduce operational costs.

ROI – Is Air Conditioning Really Worth It?

Investing in industrial air conditioning for control cabinets may seem expensive at first, but in many cases, it pays off faster than expected. Let’s analyze it through the lens of Return on Investment (ROI).

1. Extended Component Lifespan

Industrial electronics are typically designed to operate at temperatures up to 40–45°C. Exceeding this threshold leads to:

- Degradation of electrolytic capacitors,

- Shortened lifespan of power supplies and inverters,

- Decreased reliability of PLCs.

➡ It’s estimated that every +10°C above nominal temperature shortens device lifespan by 50%. This means that investing in cooling can double the lifecycle of many components.

2. Reduction of Unplanned Downtime

A control cabinet failure can stop the entire production line, and every minute of downtime costs:

- From several to tens of thousands of PLN per hour (depending on the industry),

- Additional hours of maintenance team work,

- Potential material losses and production delays.

➡ Air conditioning prevents overheating and thermal faults – reducing downtime risk.

3. Lower Maintenance Costs

Maintaining the proper temperature extends mean time between failures (MTBF), which means:

- Less frequent part replacements,

- Fewer service interventions,

- Reduced spare parts inventory and logistics costs.

4. Predictability and Monitoring

Modern industrial air conditioners (e.g., nVent SpectraCool) offer:

- Remote monitoring via Modbus/RS485,

- Temperature overrun alarms,

- Temperature trend analysis.

➡ This enables predictive maintenance and planned servicing without surprises.

Conclusion: The cost of purchasing and installing an air conditioner often pays off within 1–2 years, thanks to reduced failures and associated costs.

What to Consider When Choosing a Control Cabinet Air Conditioner?

1. Cooling Capacity (W, BTU/h)

Select the air conditioner based on the calculated thermal load. For example:

- Cabinet in a production hall: approx. 500–1000 W,

- Cabinet in an outdoor container: often over 1000 W.

It’s recommended to add a 15–20% power margin for variable factors such as rising ambient temperature or future component additions.

2. Environmental Conditions

Consider the environment in which the cabinet operates:

- Dust, dirt, oil mist → choose an air conditioner with IP54–IP66,

- High ambient temperatures → required operation range up to 55°C or more,

- Outdoor installations → models resistant to weather, preferably INOX or with anti-corrosion coating.

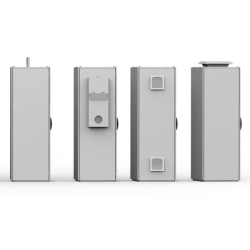

3. Mounting Type

Different mounting variants are available:

- Side-mounted – most popular, easy to service,

- Roof-mounted – saves side cabinet space,

- Internal door-mounted – if the cabinet is placed close to other equipment.

4. Communication and Integration

Modern air conditioners offer integration with SCADA/BMS systems:

- RS485, Modbus, Ethernet interfaces,

- Temperature alarms, compressor control,

- Remote management and diagnostics capabilities.

5. Manufacturer and Service

Choose devices from reputable manufacturers (e.g., nVent), who offer:

- Long-term support,

- Availability of spare parts,

- Selection tools and online calculators.

Summary

Investing in industrial control cabinet air conditioning is not just a cost – it's a way to ensure the continuity of automation and energy systems. Maintaining stable internal cabinet temperature:

- Extends the lifespan of electronic components,

- Minimizes the risk of failures and downtimes,

- Increases the reliability of control systems,

- Reduces service and equipment replacement costs.

With a properly selected cooling system, a high ROI (Return on Investment) is achievable – often within 1–2 years in environments with high dust levels or elevated temperatures.

Modern air conditioners also offer remote monitoring features, SCADA/BMS integration, and IP54–IP66 protection, making them an ideal solution for demanding industrial applications.

Related product

Related posts

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Leave a comment