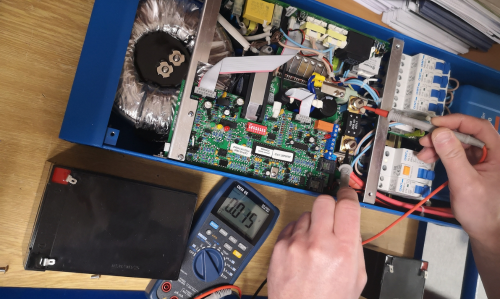

Energy installations are increasingly based on direct current – from photovoltaics, through energy storage systems, to EV charging stations. In this article, we explain what DC meters are, how they work, and where they are used. We also take a closer look at the DCBM series from LEM – advanced direct current meters that combine measurement precision with safety and the ability to bill energy in compliance with the MID standard.

Articles

-

Rogowski Coils – Construction and Principle of OperationRead more

Rogowski coils are built with a flexible core made of insulating material, around which very precise and tightly wound turns of thin, insulated wire are wrapped. The ends of the winding are connected to an electronic circuit that processes the signal.

-

Energy Efficiency in Industrial Air ConditionersRead more

In the industrial sector, where air conditioners operate continuously for many hours each day, efficient energy use directly impacts operational costs and the working environment of the equipment. This article explores what energy efficiency in industrial air conditioners truly means, the technologies behind it, and how it translates into tangible savings.

-

Testing integrated circuitsRead more

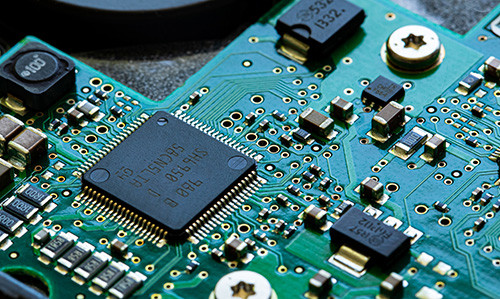

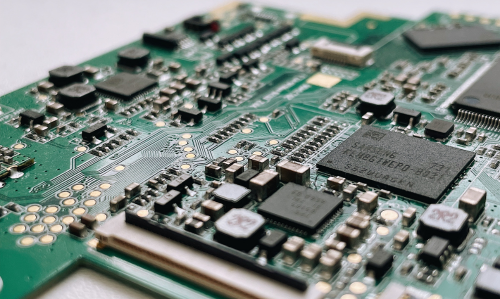

The main advantage of analyzing a device’s immunity at the integrated circuit level is that such testing does not require consideration of the influence of the circuit’s design on electromagnetic compatibility (EMC). This analysis includes, for example, the design of the printed circuit board, the nature and availability of connectors, and the enclosure. The article describes the relationship between testing at the device level and at the integrated circuit (IC) level.

-

What is EMI and why should you care about it?Read more

EMI (Electromagnetic Interference) refers to unwanted signals that can disrupt the operation of electronic devices. As electronics become smaller and more complex, they also become more susceptible to such interference. EMI can lead to errors, instability, or even system failures. That’s why proper circuit design — including electromagnetic shielding at the PCB level — is so important. This article explains how EMI shielding works, what materials to use, and how to avoid common design pitfalls.

-

How Do Air Conditioners Affect the Reliability of Industrial Automation?Read more

The increase in automation and miniaturization of components makes automation systems increasingly sensitive to environmental conditions. Overheating, moisture, and dust are the main factors that shorten equipment lifespan and lead to downtime.

-

Application of Air Conditioners in Harsh Environmental Conditions – Dust, Humidity, Extreme TemperaturesRead more

Modern industrial electronics require effective protection against overheating – even in the most extreme environmental conditions. With the increasing level of automation, miniaturization of components, and higher component density, the demand for efficient cooling systems is constantly growing. Where traditional passive methods fail, the use of specialized industrial air conditioners becomes essential – designed to operate in environments with high humidity, dust, vibrations, or extreme...

-

Why Invest in Industrial Control Cabinet Air Conditioning? ROI and Extended Component LifespanRead more

Investing in an industrial air conditioning system for control cabinets is increasingly not a luxury but a necessity—especially in applications that require continuous operation and high availability. In this article, we explain why such an investment is worth considering, how to translate it into concrete figures and return on investment (ROI), and what technical data supports this decision.

-

Intrinsic Safety - Basic Guidelines for ProceedingRead more

This article explains the process of intrinsic safety verification, covering key aspects such as zone classification, device groups, temperature classes, and cable requirements in intrinsically safe circuits. It provides five essential tips for selecting the right equipment, ensuring proper documentation, and meeting safety standards like IEC 60079-14 for explosive atmospheres.

-

Telescopic covers – what are they and why are they important?Read more

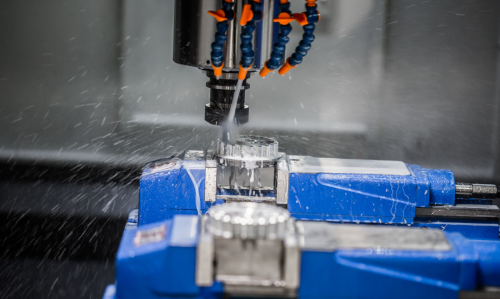

Telescopic covers are an important element of industrial machines, providing protection and longevity to equipment. Learn how these innovative solutions contribute to performance and safety, which materials are used, and what their production and repair processes look like. Discover how the right selection of telescopic covers influences the optimization of machine performance, including modern machining tools and high-speed systems

-

PVC Bellows – What Are They, How Do They Work, and What Are They Used For?Read more

PVC bellows are a popular protective solution in industry, ensuring the safety of machines and their components. Made from abrasion-resistant and chemical-resistant polyvinyl chloride, PVC bellows protect moving and stationary elements from dust, water, oils, and other harmful factors. Thanks to their flexibility and various forms (hexagonal, rectangular, curtain), they are an ideal choice for industrial machines, ensuring their longevity, reducing maintenance costs, and improving production...

-

How to Choose LED Lighting? A Guide on Durability, Testing, and ReplacementsRead more

How to Choose Durable and Efficient LED Lighting for Industrial Applications. We explain which factors influence the lifespan of LED diodes, the process of testing them, and which modern solutions – such as the SIRIO LED series or Track Alpha machine lamps – are best suited for demanding environments. This is a practical guide for anyone looking for reliable and energy-efficient lighting solutions.

-

What is the Best Lighting for Warehouses and Logistics?Read more

The article discusses the key aspects of selecting lighting for warehouses and logistics centers, highlighting LED technology, its advantages, and its application in various types of facilities. It presents types of lighting fixtures, such as linear and spotlights, and their use in spaces with different characteristics. It also includes information about emergency lighting and compliance with health and safety standards. Additionally, the article showcases lighting manufacturers such as KIRA...

-

How to Choose the Right Industrial Lighting?Read more

The article discusses key aspects of industrial lighting, including selecting appropriate fixtures for various working conditions, the use of LED technology, lighting management systems, and the impact of standards and certifications on installation quality. It also addresses challenges related to lighting in extreme temperatures and the specific requirements of different industries, such as food, chemical, or pharmaceutical sectors.

-

Anaerobic Adhesives and Their ApplicationsRead more

This article discusses the development and future of anaerobic adhesives, which play a key role in industry by ensuring the reliability and durability of threaded connections. It covers various aspects of their application in industries such as automotive, aerospace, chemical, and rail. Additionally, the article analyzes the growing demand for innovative solutions that meet the industry's needs for enhanced strength and resistance of anaerobic adhesives.

-

Top 5 Applications of Anaerobic Adhesives in IndustryRead more

Discover five applications of anaerobic adhesives in industry and their benefits for securing and sealing components. Learn how these adhesives are used in automotive, energy, medical, chemical, and machinery sectors, ensuring durability, resistance to extreme conditions, and reliability.

-

How to Choose Thread Locking Products?Read more

The article discusses how to choose the appropriate thread locking products, including anaerobic adhesives, spring washers, and tapes. The tips cover factors that influence the choice, as well as practical application advice.

-

What Are Anaerobic Adhesives?Read more

Learn about anaerobic adhesives, how they work, and the benefits they offer in challenging environments. Explore their applications in high-temperature, vibration, and pressure conditions, and discover how they contribute to the durability of threaded connections. Understand their diverse uses across industries like automotive, food production, and pharmaceuticals.