Jūs turite būti prisijungę

Category

Nuotraukos yra skirtos tik informaciniams tikslams. Peržiūrėkite produkto specifikaciją

please use latin characters

The technique of moulding conductive elastomers has a wide range of benefits. This process allows T C Shielding to manufacture components that have a very accurate tolerance requirement. Below is a list of its major advantages:

| General Description | ||||||||

|---|---|---|---|---|---|---|---|---|

| EcE Material Reference (Type) | 1A | 1B | 1D | 1F | 1G | 1I | ||

| Elastomer Type (Sil - Silicone, F/Sil - Fluorosilicone) | Sil | Sil | Sil | Sil | Sil | Sil | ||

| Filler Material | Ag/Ni | Ag/Cu | Ag/Al | Carbon | Ag | Ag/Glass | ||

| Colour | Tan | Tan | Tan | Black | Tan | Tan | ||

| Electrical Properties | Tol | Test Method | ||||||

| Volume Resistivity (ohm.cm) | Max | 0,005 | 0,005 | 0,008 | 9,000 | 0,002 | 0,005 | |

| Shielding Effectiveness (dB) 200 KHz (H-Field) |

MIL-G-83528 MIL 285 |

70 | 70 | 70 | 30 | 70 | 55 | |

| 100 MHz (E-Field) | 105 | 115 | 110 | 65 | 115 | 95 | ||

| 500 MHz (E-Field) | 105 | 115 | 105 | 60 | 115 | 95 | ||

| 2 GHz (Plane Wave) | 100 | 115 | 100 | 40 | 115 | 95 | ||

| 10 GHz (Plane Wave) | 100 | 115 | 100 | 30 | 115 | 95 | ||

| Physical Properties | ||||||||

| Specific Gravity (g/cm∆) | ±5% | ASTM D-792 | 3,71 | 3,32 | 2,19 | 1,19 | 3,20 | "2.00 75 1.25" |

| Hardness (Shore A) | ± 5 | ASTM D-2240 | 70 | 75 | 70 | 70 | 75 | |

| Tensile Strength (MPa) | Min | ASTM D-412 | 1,25 | 1,25 | 1,25 | 5,00 | 1,25 | |

| Elongation (%) | Min | ASTM D-412 | 100 | 100 | 100 | 150 | 100 | 100 |

| Compression Set (%) | Max | ASTM D-395 | 30 | 30 | 30 | 20 | 30 | 30 |

| Upper Operating Temperature (°C) | - | 160 | 125 | 160 | 160 | 160 | 160 | |

| Lower Operating Temperature (°C) | - | ASTM D-1329 | -50 | -50 | -50 | -50 | -50 | -50 |

| General Description | ||||||||

|---|---|---|---|---|---|---|---|---|

| EcE Material Reference (Type) | 1J | 1J/8 | 2A | 2B | 2D | 2J | ||

| Non Flam | ||||||||

| Elastomer Type (Sil - Silicone, F/Sil - Fluorosilicone) | Sil | Sil | F/Sil | F/Sil | F/Sil | F/Sil | ||

| Filler Material | Ni/Gr | Ni/Gr | Ag/Ni | Ag/Cu | Ag/Al | Ni/Gr | ||

| Colour | szary | szary | Tan | Tan | Green | Green | ||

| Electrical Properties | Tol | Test Method | ||||||

| Volume Resistivity (ohm.cm) | Max | 0,05 | "0.050- | 0,005 | 0,005 | 0,01 | 0,05 | |

| 0.100" | ||||||||

| Shielding Effectiveness (dB) | MIL-G-83528 | |||||||

| 200 KHz (H-Field) | MIL 285 | 70 | 70 | 75 | 75 | 70 | 70 | |

| 100 MHz (E-Field) | 95 | 95 | 110 | 110 | 110 | 100 | ||

| 500 MHz (E-Field) | 90 | 90 | 110 | 120 | 105 | 100 | ||

| 2 GHz (Plane Wave) | 90 | 90 | 105 | 120 | 100 | 100 | ||

| 10 GHz (Plane Wave) | 90 | 90 | 100 | 120 | 100 | 100 | ||

| Physical Properties | ||||||||

| Specific Gravity (g/cm∆) | ±5% | ASTM D-792 | 2,45 | 2,3 | 4,6 | 5 | 2,7 | 3,25 |

| Hardness (Shore A) | ± 5 | ASTM D-2240 | 80 | 75 | 80 | 75 | 70 | 80 |

| Tensile Strength (MPa) | Min | ASTM D-412 | 2 | 1,4 | 1,25 | 1,25 | 0,55 | 0,75 |

| Elongation (%) | Min | ASTM D-412 | 150 | 125 | 100 | 100 | 100 | 100 |

| Compression Set (%) | Max | ASTM D-395 | 30 | 30 | 30 | 30 | 30 | 30 |

| Upper Operating Temperature (°C) | - | 160 | 160 | 160 | 125 | 160 | 160 | |

| Lower Operating Temperature (°C) | - | ASTM D-1329 | -50 | -50 | -50 | -55 | -55 | -55 |

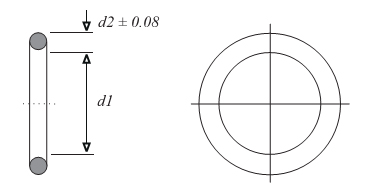

Rear Mounting Jam Nut Receptacle ‘O’ Rings

| Shell size | MIL C 38999 MIL C 26482 | MIL C 81511 | d1 | Tol d1 ± | d2 |

|---|---|---|---|---|---|

| TC REF | TC REF | mm | mm | mm | |

| 6 | 1 | - | 14.00 | 0.13 | 1.78 |

| 8 | 2 | - | 17.16 | 0.13 | 1.78 |

| 8 | - | 3 | 18.77 | 0.13 | 1.78 |

| 9 | 4 | - | 20.35 | 0.15 | 1.78 |

| 10 | - | 5 | 21.95 | 0.15 | 1.78 |

| 11+12 | 6 | - | 25.12 | 0.15 | 1.78 |

| 13+14 | 7 | 7 | 28.30 | 0.15 | 1.78 |

| 15+16 | 8 | 8 | 31.47 | 0.15 | 1.78 |

| 17+18 | 9 | 9 | 34.65 | 0.15 | 1.78 |

| 19+20 | 10 | - | 37.77 | 0.15 | 2.62 |

| 21+22 | 11 | - | 40.95 | 0.25 | 2.62 |

| 23+24 | 12 | - | 44.12 | 0.25 | 2.62 |

MA - XX - XXX

Example: MA

MA - Moulded Ring

3A - Silver Aluminium/Silicone

001 - Shell size

Cost Effective Alternative To Conductive Moulded O-Rings

T.C.Shielding have developed a range of extruded/jointed O-Rings that offer a cost effective alternative to traditionally moulded items with added benefits, and compatible tolerancing. The following are benefits of this new process.

Below is a comparison between moulded and jointed tolerances

Moulded O-ring

ID = 25.12+/-0.15

Section = 1.78+/-0.08

Developed Lenght= 84.04/84.98

Ext./Jointed O-ring

ID = 25.12+/-0.16

Cross section= 1.78+/-0.10

Developed Length= 84.00/85.00

Ar Jūs domina šis produktas? Ar Jums reikia papildomos informacijos ar individualaus pasiūlymo?

tu turi būti prisijungęs

The technique of moulding conductive elastomers has a wide range of benefits. This process allows T C Shielding to manufacture components that have a very accurate tolerance requirement. Below is a list of its major advantages:

| General Description | ||||||||

|---|---|---|---|---|---|---|---|---|

| EcE Material Reference (Type) | 1A | 1B | 1D | 1F | 1G | 1I | ||

| Elastomer Type (Sil - Silicone, F/Sil - Fluorosilicone) | Sil | Sil | Sil | Sil | Sil | Sil | ||

| Filler Material | Ag/Ni | Ag/Cu | Ag/Al | Carbon | Ag | Ag/Glass | ||

| Colour | Tan | Tan | Tan | Black | Tan | Tan | ||

| Electrical Properties | Tol | Test Method | ||||||

| Volume Resistivity (ohm.cm) | Max | 0,005 | 0,005 | 0,008 | 9,000 | 0,002 | 0,005 | |

| Shielding Effectiveness (dB) 200 KHz (H-Field) |

MIL-G-83528 MIL 285 |

70 | 70 | 70 | 30 | 70 | 55 | |

| 100 MHz (E-Field) | 105 | 115 | 110 | 65 | 115 | 95 | ||

| 500 MHz (E-Field) | 105 | 115 | 105 | 60 | 115 | 95 | ||

| 2 GHz (Plane Wave) | 100 | 115 | 100 | 40 | 115 | 95 | ||

| 10 GHz (Plane Wave) | 100 | 115 | 100 | 30 | 115 | 95 | ||

| Physical Properties | ||||||||

| Specific Gravity (g/cm∆) | ±5% | ASTM D-792 | 3,71 | 3,32 | 2,19 | 1,19 | 3,20 | "2.00 75 1.25" |

| Hardness (Shore A) | ± 5 | ASTM D-2240 | 70 | 75 | 70 | 70 | 75 | |

| Tensile Strength (MPa) | Min | ASTM D-412 | 1,25 | 1,25 | 1,25 | 5,00 | 1,25 | |

| Elongation (%) | Min | ASTM D-412 | 100 | 100 | 100 | 150 | 100 | 100 |

| Compression Set (%) | Max | ASTM D-395 | 30 | 30 | 30 | 20 | 30 | 30 |

| Upper Operating Temperature (°C) | - | 160 | 125 | 160 | 160 | 160 | 160 | |

| Lower Operating Temperature (°C) | - | ASTM D-1329 | -50 | -50 | -50 | -50 | -50 | -50 |

| General Description | ||||||||

|---|---|---|---|---|---|---|---|---|

| EcE Material Reference (Type) | 1J | 1J/8 | 2A | 2B | 2D | 2J | ||

| Non Flam | ||||||||

| Elastomer Type (Sil - Silicone, F/Sil - Fluorosilicone) | Sil | Sil | F/Sil | F/Sil | F/Sil | F/Sil | ||

| Filler Material | Ni/Gr | Ni/Gr | Ag/Ni | Ag/Cu | Ag/Al | Ni/Gr | ||

| Colour | szary | szary | Tan | Tan | Green | Green | ||

| Electrical Properties | Tol | Test Method | ||||||

| Volume Resistivity (ohm.cm) | Max | 0,05 | "0.050- | 0,005 | 0,005 | 0,01 | 0,05 | |

| 0.100" | ||||||||

| Shielding Effectiveness (dB) | MIL-G-83528 | |||||||

| 200 KHz (H-Field) | MIL 285 | 70 | 70 | 75 | 75 | 70 | 70 | |

| 100 MHz (E-Field) | 95 | 95 | 110 | 110 | 110 | 100 | ||

| 500 MHz (E-Field) | 90 | 90 | 110 | 120 | 105 | 100 | ||

| 2 GHz (Plane Wave) | 90 | 90 | 105 | 120 | 100 | 100 | ||

| 10 GHz (Plane Wave) | 90 | 90 | 100 | 120 | 100 | 100 | ||

| Physical Properties | ||||||||

| Specific Gravity (g/cm∆) | ±5% | ASTM D-792 | 2,45 | 2,3 | 4,6 | 5 | 2,7 | 3,25 |

| Hardness (Shore A) | ± 5 | ASTM D-2240 | 80 | 75 | 80 | 75 | 70 | 80 |

| Tensile Strength (MPa) | Min | ASTM D-412 | 2 | 1,4 | 1,25 | 1,25 | 0,55 | 0,75 |

| Elongation (%) | Min | ASTM D-412 | 150 | 125 | 100 | 100 | 100 | 100 |

| Compression Set (%) | Max | ASTM D-395 | 30 | 30 | 30 | 30 | 30 | 30 |

| Upper Operating Temperature (°C) | - | 160 | 160 | 160 | 125 | 160 | 160 | |

| Lower Operating Temperature (°C) | - | ASTM D-1329 | -50 | -50 | -50 | -55 | -55 | -55 |

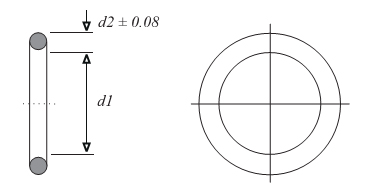

Rear Mounting Jam Nut Receptacle ‘O’ Rings

| Shell size | MIL C 38999 MIL C 26482 | MIL C 81511 | d1 | Tol d1 ± | d2 |

|---|---|---|---|---|---|

| TC REF | TC REF | mm | mm | mm | |

| 6 | 1 | - | 14.00 | 0.13 | 1.78 |

| 8 | 2 | - | 17.16 | 0.13 | 1.78 |

| 8 | - | 3 | 18.77 | 0.13 | 1.78 |

| 9 | 4 | - | 20.35 | 0.15 | 1.78 |

| 10 | - | 5 | 21.95 | 0.15 | 1.78 |

| 11+12 | 6 | - | 25.12 | 0.15 | 1.78 |

| 13+14 | 7 | 7 | 28.30 | 0.15 | 1.78 |

| 15+16 | 8 | 8 | 31.47 | 0.15 | 1.78 |

| 17+18 | 9 | 9 | 34.65 | 0.15 | 1.78 |

| 19+20 | 10 | - | 37.77 | 0.15 | 2.62 |

| 21+22 | 11 | - | 40.95 | 0.25 | 2.62 |

| 23+24 | 12 | - | 44.12 | 0.25 | 2.62 |

MA - XX - XXX

Example: MA

MA - Moulded Ring

3A - Silver Aluminium/Silicone

001 - Shell size

Cost Effective Alternative To Conductive Moulded O-Rings

T.C.Shielding have developed a range of extruded/jointed O-Rings that offer a cost effective alternative to traditionally moulded items with added benefits, and compatible tolerancing. The following are benefits of this new process.

Below is a comparison between moulded and jointed tolerances

Moulded O-ring

ID = 25.12+/-0.15

Section = 1.78+/-0.08

Developed Lenght= 84.04/84.98

Ext./Jointed O-ring

ID = 25.12+/-0.16

Cross section= 1.78+/-0.10

Developed Length= 84.00/85.00

Jūsų atsiliepimo įvertinimas negali būti išsiųstas

Pranešti apie komentarą

Pranešimas apie atsiliepimą išsiųstas

Jūsų pranešimas apie atsiliepimą neišsiųstas

Parašyti savo atsiliepimą

Atsiliepimas išsiųstas

Jūsų atsiliepimas neišsiųstas