Vous devez être connecté

Category

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

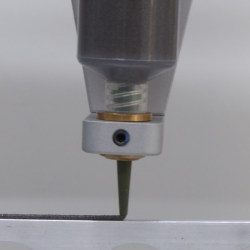

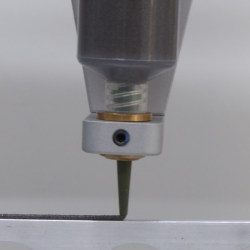

Formed-in-place gaskets are also known as FIP or FIP-G, and they are a type of gasket that is automatically dispensed in the form of standard silicone or material that conducts electromagnetic interference (EMI). These types of gaskets are becoming increasingly popular in the electronics industry due to the dense design of modern electronic device enclosures. Our Form in Place gaskets are specifically designed to provide a seamless and effective solution for challenging sealing applications commonly encountered in complex electronics. Thanks to the automatic dispensing of silicone, FIP gaskets offer excellent sealing properties and reduce the likelihood of leaks, even in applications where traditional gaskets have failed in the past. The key feature that distinguishes EMI Form-in-Place gaskets is that they are developed for applications requiring inter-chamber isolation to separate signal processing and/or signal generating functions. FIP gaskets aim to reduce "noise" between compartments on a printed circuit board (PCB) or in an electronic housing. Additionally, FIP gaskets provide excellent electrical contact with adjacent conductive surfaces, including printed circuit board tracks, ensuring isolation between compartments. We offer a fast, free sample delivery service and can produce single parts up to large production batches. Typically, we require a DXF file of the part. This speeds up programming time and reduces lead time from receipt to completion of the product.

| Property | FP-SA | FP-SC | FP-SN | FP-NC |

|---|---|---|---|---|

| Filler | Silver Aluminum | GF-SA | GF-DS | GF-NC |

| Ag/Al | Silver Copper | Light Brown | Light Brown | Light Brown |

| Ag/Cu | Silver Nickel | 12 hours | 12 hours | 12 hours |

| Ag/Ni | Nickel Graphite | 1 week | 1 week | 1 week |

| Ni/C | 2 g/cm³ | 2 g/cm³ | 2.7 g/cm³ | 2.7 g/cm³ |

| Color | Light Brown | Light Brown | Light Brown | Dark Gray |

| Curing Time | 10 hours | 10 hours | 10 hours | 10 hours |

| Recommended Minimum Curing Time | 24 hours | 24 hours | 24 hours | 24 hours |

| Density | 2 g/cm³ | 3 g/cm³ | 3.6 g/cm³ | 2.5 g/cm³ |

| Hardness | 50 Shore A | 40 Shore A | 45 Shore A | 50 Shore A |

| Volume Resistivity | <0.01 Ω·cm | <0.01 Ω·cm | <0.01 Ω·cm | <0.1 Ω·cm |

| Adhesion | >50 N/cm² | >50 N/cm² | >50 N/cm² | >50 N/cm² |

| Damping (100 MHz–10 GHz) | 85–110 dB | 100–120 dB | 90–110 dB | 85–110 dB |

| Recommended Compression | 25 % | 25 % | 25 % | 25 % |

| Gasket Resistance | <0.5 Ω/cm | <0.5 Ω/cm | <0.5 Ω/cm | <0.5 Ω/cm |

| Elongation | 100 % | 100 % | 100 % | 100 % |

| Permanent Compression Set (70 h/23 °C) | <20 % | <20 % | <20 % | <20 % |

| Operating Temperature Range | –55 °C to 150 °C | –55 °C to 125 °C | –55 °C to 150 °C | –55 °C to 150 °C |

| Bending Force @10 % | 1.5 N/cm | 1.4 N/cm | 1.7 N/cm | 2.8 N/cm |

| Bending Force @25 % | 3.5 N/cm | 3.3 N/cm | 4.1 N/cm | 7.4 N/cm |

| Bending Force @50 % | 16.0 N/cm | 14.8 N/cm | 20.7 N/cm | 26.4 N/cm |

In addition to custom dispensed gaskets, these materials are also available in containers with capacities of 10 cm³,

30 cm³, 55 cm³, 70 cm³, 170 cm³, and 310 cm³.

We also offer materials based on standard silicone and fluorosilicone.

.jpeg)

.jpeg)

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Formed-in-place gaskets are also known as FIP or FIP-G, and they are a type of gasket that is automatically dispensed in the form of standard silicone or material that conducts electromagnetic interference (EMI). These types of gaskets are becoming increasingly popular in the electronics industry due to the dense design of modern electronic device enclosures. Our Form in Place gaskets are specifically designed to provide a seamless and effective solution for challenging sealing applications commonly encountered in complex electronics. Thanks to the automatic dispensing of silicone, FIP gaskets offer excellent sealing properties and reduce the likelihood of leaks, even in applications where traditional gaskets have failed in the past. The key feature that distinguishes EMI Form-in-Place gaskets is that they are developed for applications requiring inter-chamber isolation to separate signal processing and/or signal generating functions. FIP gaskets aim to reduce "noise" between compartments on a printed circuit board (PCB) or in an electronic housing. Additionally, FIP gaskets provide excellent electrical contact with adjacent conductive surfaces, including printed circuit board tracks, ensuring isolation between compartments. We offer a fast, free sample delivery service and can produce single parts up to large production batches. Typically, we require a DXF file of the part. This speeds up programming time and reduces lead time from receipt to completion of the product.

| Property | FP-SA | FP-SC | FP-SN | FP-NC |

|---|---|---|---|---|

| Filler | Silver Aluminum | GF-SA | GF-DS | GF-NC |

| Ag/Al | Silver Copper | Light Brown | Light Brown | Light Brown |

| Ag/Cu | Silver Nickel | 12 hours | 12 hours | 12 hours |

| Ag/Ni | Nickel Graphite | 1 week | 1 week | 1 week |

| Ni/C | 2 g/cm³ | 2 g/cm³ | 2.7 g/cm³ | 2.7 g/cm³ |

| Color | Light Brown | Light Brown | Light Brown | Dark Gray |

| Curing Time | 10 hours | 10 hours | 10 hours | 10 hours |

| Recommended Minimum Curing Time | 24 hours | 24 hours | 24 hours | 24 hours |

| Density | 2 g/cm³ | 3 g/cm³ | 3.6 g/cm³ | 2.5 g/cm³ |

| Hardness | 50 Shore A | 40 Shore A | 45 Shore A | 50 Shore A |

| Volume Resistivity | <0.01 Ω·cm | <0.01 Ω·cm | <0.01 Ω·cm | <0.1 Ω·cm |

| Adhesion | >50 N/cm² | >50 N/cm² | >50 N/cm² | >50 N/cm² |

| Damping (100 MHz–10 GHz) | 85–110 dB | 100–120 dB | 90–110 dB | 85–110 dB |

| Recommended Compression | 25 % | 25 % | 25 % | 25 % |

| Gasket Resistance | <0.5 Ω/cm | <0.5 Ω/cm | <0.5 Ω/cm | <0.5 Ω/cm |

| Elongation | 100 % | 100 % | 100 % | 100 % |

| Permanent Compression Set (70 h/23 °C) | <20 % | <20 % | <20 % | <20 % |

| Operating Temperature Range | –55 °C to 150 °C | –55 °C to 125 °C | –55 °C to 150 °C | –55 °C to 150 °C |

| Bending Force @10 % | 1.5 N/cm | 1.4 N/cm | 1.7 N/cm | 2.8 N/cm |

| Bending Force @25 % | 3.5 N/cm | 3.3 N/cm | 4.1 N/cm | 7.4 N/cm |

| Bending Force @50 % | 16.0 N/cm | 14.8 N/cm | 20.7 N/cm | 26.4 N/cm |

In addition to custom dispensed gaskets, these materials are also available in containers with capacities of 10 cm³,

30 cm³, 55 cm³, 70 cm³, 170 cm³, and 310 cm³.

We also offer materials based on standard silicone and fluorosilicone.

.jpeg)

.jpeg)

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé