Vous devez être connecté

-

WróćX

-

Composants

-

-

Category

-

Semi-conducteurs

- La diode

- Les thyristors

- Modules de puissance isolés

- Ponts redresseurs

-

Transistors

- Transistors | GeneSiC

- Modules MOSFET SiC | Mitsubishi

- Modules MOSFET SiC | STARPOWER

- Modules MOSFET SiC ABB

- Modules IGBT | MITSUBISHI

- Modules de transistors | MITSUBISHI

- Modules MOSFET | MITSUBISHI

- Modules de transistors | ABB

- Modules IGBT | POWEREX

- Modules IGBT | INFINEON (EUPEC)

- Composants semiconducteurs en carbure de silicium

- Przejdź do podkategorii

- Circuits de commande

- Blocs de puissance

- Przejdź do podkategorii

- Transducteurs électriques

-

Composants passifs (condensateurs, résistances, fusibles, filtres)

- Résistances

-

Fusibles

- Fusibles miniatures pour c.imp. série ABC et AGC

- Fusible rapides tubulaires

- Cartouches de courbe GL/GG et AM

- Cartouches ultrarapides

- Fusibles à action rapide (norme britannique et américaine)

- Fusibles à action rapide (norme européenne)

- Fusibles de traction

- Cartouche de haute tension

- Przejdź do podkategorii

-

Condensateurs

- Condensateurs pour moteurs

- Condensateurs électrolitiques

- Condensateurs de type snubbers

- Condensateurs de puissance

- Condensateurs pour circuits continus

- Condensateurs de compensation de puissance

- Condensateurs de haute tension

- Condensateurs pour chauffage par induction

- Condensateurs pour impulsions

- Condensateurs DC LINK

- Condensateurs pour circuits AC/DC

- Przejdź do podkategorii

- Filtres anti-interférences

- Supercondensateurs

- Protection contre les surtensions

- Filtres de détection des émissions TEMPEST

- Parafoudre

- Przejdź do podkategorii

-

Relais et contacteurs

- Théorie relais et contacteurs

- Relais statiques triphasés

- Relais statiques CC

- Régulateurs, circuits de commande et accessoires

- Démarrages progressifs et contacteurs inverseurs

- Relais electromécaniques

- Contacteurs

- Commutateurs rotatifs

-

Relais statiques monophasés

- Relais semi-conducteurs AC monophasés, série 1 | D2425 | D2450

- Relais à semi-conducteurs CA monophasés, séries CWA et CWD

- Relais à semi-conducteurs CA monophasés des séries CMRA et CMRD

- Relais à semi-conducteurs CA monophasés, série PS

- Relais semi-conducteurs AC double et quadruple, série D24 D, TD24 Q, H12D48 D

- Relais statiques monophasés, série GN

- Relais à semi-conducteurs CA monophasés, série CKR

- Relais AC monophasés SÉRIES ERDA ET ERAA pour rail DIN

- Relais CA monophasés pour courant 150A

- Relais à semi-conducteurs doubles intégrés à un dissipateur thermique pour un rail DIN

- Przejdź do podkategorii

- Relais statiques monophasé pour c.imp.

- Relais d'interface

- Przejdź do podkategorii

- Composants inductifs

- Radiateurs, varistances, protections thermiques

- Ventilateurs

- Climatiseurs et accessoires d'armoires électriques

-

Batteries, chargeurs, blocs d'alimentation tampon et onduleurs

- Batteries et Chargeurs - théorie

- Batteries Li-ion et non-standards. Systèmes de gestion des batteries (BMS)

- Batteries

- Chargeurs de batteries et accessoires

- Alimentation de secours UPS et alimentation tampon

- Convertisseurs de tension et accessoires pour photovoltaïque

- Stockage d'Energie

- Réservoirs de carburant

- Batteries lithium-ion

- Przejdź do podkategorii

-

Automatique industrielle

- Élévateurs Spiralift

- Pièces pour drones Futaba

- Interrupteurs de fin de course, micro-rupteurs

- Capteurs et convertisseurs

- Pyromètres

- Compteurs, Relais temporisés, Indicateurs de tableau

- Appareils industriels de protection

- Signalisation lumineuse et sonore

- Caméra thermique

- Afficheurs à LED

- Boutons et commutateurs

- Przejdź do podkategorii

-

Câbles et chemins de câbles

- Fils

- Passe-câbles et coupleurs

- Fils de Litz

- Câbles pour les applications spéciales

- Gaines

-

Tresses

- Tresses plates

- Tresses rondes

- Tresses très souples - plates

- Tresses très souples - rondes

- Tresses cuivre cylindriques

- Tresses cuivre cylindriques et protection

- Bandes de mise à la terre souples

- Tresses en acier zingué et inox

- Tresses isolantes en PVC - temp. 85°C

- Tresses plates en aluminium

- Kit de liaison - tresses et gaines

- Przejdź do podkategorii

- Equipement pour la traction

- Cosses

- Barres flexible isolées

- Barre flexibles multicouches

- Systèmes de traçage des câbles

- Przejdź do podkategorii

- Contactez-nous !

-

Semi-conducteurs

-

-

- Fournisseurs

-

Applications

- Alimentations (UPS) et systèmes de redressement

- Automatisation HVAC

- Automatisation industrielle

- Chauffage par induction

- Composants pour atmosphères potentiellement explosives (EX)

- Dispositifs de protection industriels

- Énergétique

- Energy bank

- Équipements pour armoires de distribution, de contrôle et de télécommunications

- Impression

- Machines à souder et machines à souder

- Machines de séchage et de traitement du bois

- Machines pour le thermoformage des plastiques

- Machines-outils CNC

- Mesure et régulation de la température

- Mesure et régulation de la température

- Mines, métallurgie et fondation

- Moteurs et transformateurs

- Traction de tram et de chemin de fer

- Variateurs CA et CC (onduleurs)

-

Installation

-

-

Inducteurs

-

-

Appareils à induction

-

-

Service

-

- Contact

- Zobacz wszystkie kategorie

Application of Air Conditioners in Harsh Environmental Conditions – Dust, Humidity, Extreme Temperatures

Demanding Work Environments – Challenges for Cooling Systems

In harsh working environments, cooling systems must meet additional requirements:

- Resistance to dust, dirt, and metal particles,

- Operation in a wide temperature range,

- Protection against moisture, condensation, and salinity,

- Mechanical durability (vibrations, impacts),

- Easy maintenance and reliability,

- Integration with remote monitoring systems.

Proper selection of an air conditioner has a real impact on production continuity and minimizing downtime risk.

Application Examples – Industries and Real Challenges

1. Energy Sector

- High ambient temperatures, often above 40°C,

- 24/7 operation in transformer stations and switchgear,

- Dust presence in coal-fired power plants or CHP plants.

2. Food Industry

- High humidity, risk of condensation,

- Frequent equipment cleaning with chemical agents,

- Required hygienic design (stainless steel, IP66).

3. Mining and Heavy Industry

- Extreme dust, presence of metal shavings,

- Strong vibrations, limited service access,

- Required maintenance-free operation and mechanical resistance.

4. Offshore and Marine Infrastructure

- Air salinity, rapid material corrosion,

- Extreme weather conditions,

- Required long lifespan and integration with remote systems.

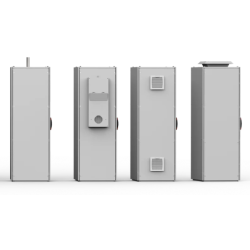

nVent Air Conditioners – Ready Solutions for Harsh Environments

nVent, a renowned manufacturer of industrial cooling solutions, offers a wide range of air conditioners specifically designed for demanding environments:

- Enclosures made of stainless steel or with anti-corrosion coating,

- High IP protection rating (up to IP66),

- Large surface filters and additional protection options,

- Extended operating temperature range (e.g., from -40°C to +60°C),

- Remote monitoring capability (Modbus, RS485),

- SpectraCool series: wide selection of power ratings and mounting options.

DACPOL, as an authorized nVent distributor in Poland, provides full technical support – from selection to servicing.

How to Choose the Right Air Conditioner for Demanding Applications?

- Environmental conditions – temperature, humidity, dust, vibrations,

- Cabinet heat balance – amount of generated heat,

- IP protection rating and material requirements,

- Service possibilities and integration with SCADA/BMS systems,

- Project support – calculators and consultations with a DACPOL engineer.

Summary – Safety, Reliability, and Investment Protection

A properly selected industrial air conditioner is an investment that significantly impacts the operational safety of the entire automation system. nVent products, thanks to their reliability and resistance to the toughest conditions, ensure long-term, trouble-free operation. In cooperation with DACPOL, customers gain access not only to proven technology but also to comprehensive technical and advisory support.

Produit associé

Articles similaires

Thermally conductive materials in power storages

Thermally conductive materials in power storages

Measuring power and energy in electric circuits

Measuring power and energy in electric circuits

Wentylatory przemysłowe - rodzaje, właściwości

Wentylatory przemysłowe - rodzaje, właściwości

Laissez un commentaire