Vous devez être connecté

Category

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

To keep up with the growing market for television picture tubes, manufacturers are constantly searching for faster, more cost-effective production techniques.

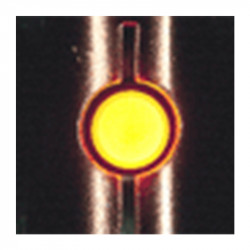

One such method is to insert or "seal" metal anchoring pins to the TV picture tube glass panels. The pins, which may be solid or hollow in design, aid in the assembly process by providing a mounting support for the phosphor shadow mask and cathode ray tube.

Temperature requirements for pin sealing are stringent due to the delicate nature of glass and the importance of a quality insertion.

Modern induction heating systems have the precision and speed required to make television picture glass pin sealing a production process. One or more pins are typically heated to approximately 1100°C for insertion into the glass panel. At the time of insertion, the glass panel is still at what is known as the softening point (400°C). Glass at the softening point has a viscosity equal to or less than 4x106 Pa-s, allowing the panel to be handled without causing significant dimensional alterations. Typical frequencies for pin sealing are 200 to 700 kHz, depending on how many pins are being heated

Typical induction systems typically used for pin sealing range from 3 to 20 kW, depending on the parts and application requirements.

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

To keep up with the growing market for television picture tubes, manufacturers are constantly searching for faster, more cost-effective production techniques.

One such method is to insert or "seal" metal anchoring pins to the TV picture tube glass panels. The pins, which may be solid or hollow in design, aid in the assembly process by providing a mounting support for the phosphor shadow mask and cathode ray tube.

Temperature requirements for pin sealing are stringent due to the delicate nature of glass and the importance of a quality insertion.

Modern induction heating systems have the precision and speed required to make television picture glass pin sealing a production process. One or more pins are typically heated to approximately 1100°C for insertion into the glass panel. At the time of insertion, the glass panel is still at what is known as the softening point (400°C). Glass at the softening point has a viscosity equal to or less than 4x106 Pa-s, allowing the panel to be handled without causing significant dimensional alterations. Typical frequencies for pin sealing are 200 to 700 kHz, depending on how many pins are being heated

Typical induction systems typically used for pin sealing range from 3 to 20 kW, depending on the parts and application requirements.

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé