Debes estar logueado

Category

Las fotos son solo para fines informativos. Ver especificaciones de producto

please use latin characters

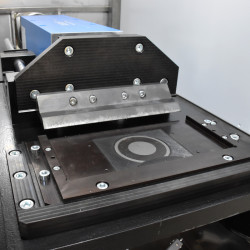

A machine designed to test the force required to rip the mesh from prepared workpieces.

General information

The machine consists of an electrical system (control system) based on Kistler's system and an operating chamber consisting mainly of a servo motor and a strain gauge. At the end of the servo motor there is a knife for tearing the mesh and an electromagnet. Depending on the shape of the workpiece and the mesh welding points, we select a knife and an electromagnet suitable for the tested workpieces.

Testing is performed in the following steps:

Each tester is additionally equipped with a barcode scanner, which allows for scanning the batch number of a given detail and sending it to the server. Thanks to this, it is possible to keep an up-to-date database of tested details.

The tester is made to individual orders.

The mesh ripping tester is used in:

Technical data

| Power supply | 3x400 VAC, 50 Hz |

| Max. input current | 32 A |

| Max. servo press force | 30 kN |

| Weight | 700 kg |

¿Estás interesado en este producto? ¿Necesita información adicional o precios individuales?

Usted debe estar conectado

A machine designed to test the force required to rip the mesh from prepared workpieces.

General information

The machine consists of an electrical system (control system) based on Kistler's system and an operating chamber consisting mainly of a servo motor and a strain gauge. At the end of the servo motor there is a knife for tearing the mesh and an electromagnet. Depending on the shape of the workpiece and the mesh welding points, we select a knife and an electromagnet suitable for the tested workpieces.

Testing is performed in the following steps:

Each tester is additionally equipped with a barcode scanner, which allows for scanning the batch number of a given detail and sending it to the server. Thanks to this, it is possible to keep an up-to-date database of tested details.

The tester is made to individual orders.

The mesh ripping tester is used in:

Technical data

| Power supply | 3x400 VAC, 50 Hz |

| Max. input current | 32 A |

| Max. servo press force | 30 kN |

| Weight | 700 kg |

Su agradecimiento a la reseña no pudo ser enviado

Reportar comentario

Reporte enviado

Su reporte no pudo ser enviado

Escriba su propia reseña

Reseña enviada

Su reseña no pudo ser enviada