Vous devez être connecté

Category

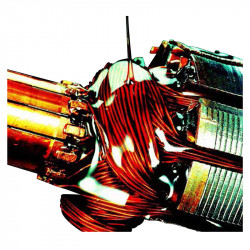

Les photos sont à titre informatif uniquement. Voir les spécifications du produit

please use latin characters

Application:

- winding protection,

- electro technical devices

- dry transformers.

Main characteristics:

- coloured lacquer, they have excellent protection preferences.

-for class B-G 141,

- for class F- G 142 - G 145,

- those lacquers have advantage, that they dry in air

- soft drying at 80°C make fast polymerisation.

- lacquer G 144 T is often used as end lacquer in dry transformers,

- those lacquers exists in tropical execution as: G 141 T - G 142 T - G 144 T - G 145 T.

Impregnation:

By brush, immersion or pistol after giving 5-10% diluent. .

Polymerisation (see table):

Possibility to dry in temperature 80 -100°C,a.

In case putting several layers it is obligatory do dry previous layer first. If we want to obtain good resistance for diluents, salt fog, or chemicals it is we must dry it for 2 hours in temperature 130°C.

Storage conditions:

Six months in original and closed package, hidden from the sun or any heat source.

Packing:

Containers 1, 5, 30 l or spray.

Hygiene and protection:

Lacquer G 142 consists ksylen.

| Characteristic | G 144T | G 142 | G 145 |

|---|---|---|---|

| Chemical origins | gliceroftalowe | modified alkyds | modified alkyds |

| Thermal class | B | F | F |

| pseudo-viscosity NFT 30,014 section 4 @ 20°C |

165s±30 | 250s±30 | 250s±30 |

| density @ 20°C NFT 30,020 | 1,14 | 1,16 | 1,11 |

| Dry extract NFT 30,011 | 63 ±2 | 60 ±2 | 60 ±2 |

| Ignition point NFT 30,050 | 34°C | 26°C | 34°C |

| Colour | black | red | red, white, blue |

| Drying on a plate @ 20°C | 5h | 15h | 5h |

| Drying on a coil @ 20°C | 8h | 24h | 6h |

| Diluent | 37004 | 37022 | 37004 |

| Marking |  |

|

|

| Breakdown voltage on a plate (lacquer thickness 0,01 mm) [V] |

Natural state | 700 | 900 | 1400 | 700 |

|---|---|---|---|---|---|

| After 8 days;in humid air | 500 | 680 | 1200 | 500 | |

| After 8 days;in destilated water | 450 | 660 | 1200 | 450 | |

| After 8 days;in transformer oil | 800 | 1000 | 1500 | 800 |

Êtes-vous intéressé par ce produit? Avez-vous besoin d'informations supplémentaires ou d'une tarification individuelle?

Ajouter à la liste de souhaits

Vous devez être connecté

Application:

- winding protection,

- electro technical devices

- dry transformers.

Main characteristics:

- coloured lacquer, they have excellent protection preferences.

-for class B-G 141,

- for class F- G 142 - G 145,

- those lacquers have advantage, that they dry in air

- soft drying at 80°C make fast polymerisation.

- lacquer G 144 T is often used as end lacquer in dry transformers,

- those lacquers exists in tropical execution as: G 141 T - G 142 T - G 144 T - G 145 T.

Impregnation:

By brush, immersion or pistol after giving 5-10% diluent. .

Polymerisation (see table):

Possibility to dry in temperature 80 -100°C,a.

In case putting several layers it is obligatory do dry previous layer first. If we want to obtain good resistance for diluents, salt fog, or chemicals it is we must dry it for 2 hours in temperature 130°C.

Storage conditions:

Six months in original and closed package, hidden from the sun or any heat source.

Packing:

Containers 1, 5, 30 l or spray.

Hygiene and protection:

Lacquer G 142 consists ksylen.

| Characteristic | G 144T | G 142 | G 145 |

|---|---|---|---|

| Chemical origins | gliceroftalowe | modified alkyds | modified alkyds |

| Thermal class | B | F | F |

| pseudo-viscosity NFT 30,014 section 4 @ 20°C |

165s±30 | 250s±30 | 250s±30 |

| density @ 20°C NFT 30,020 | 1,14 | 1,16 | 1,11 |

| Dry extract NFT 30,011 | 63 ±2 | 60 ±2 | 60 ±2 |

| Ignition point NFT 30,050 | 34°C | 26°C | 34°C |

| Colour | black | red | red, white, blue |

| Drying on a plate @ 20°C | 5h | 15h | 5h |

| Drying on a coil @ 20°C | 8h | 24h | 6h |

| Diluent | 37004 | 37022 | 37004 |

| Marking |  |

|

|

| Breakdown voltage on a plate (lacquer thickness 0,01 mm) [V] |

Natural state | 700 | 900 | 1400 | 700 |

|---|---|---|---|---|---|

| After 8 days;in humid air | 500 | 680 | 1200 | 500 | |

| After 8 days;in destilated water | 450 | 660 | 1200 | 450 | |

| After 8 days;in transformer oil | 800 | 1000 | 1500 | 800 |

Votre avis ne peut pas être envoyé

Signaler le commentaire

Signalement envoyé

Votre signalement ne peut pas être envoyé

Donnez votre avis

Avis envoyé

Votre avis ne peut être envoyé