Musisz być zalogowany/a

Kategória

A fényképek csak tájékoztató jellegűek. Lásd a termék specifikációit

Kérjük, használjon latin karaktereket

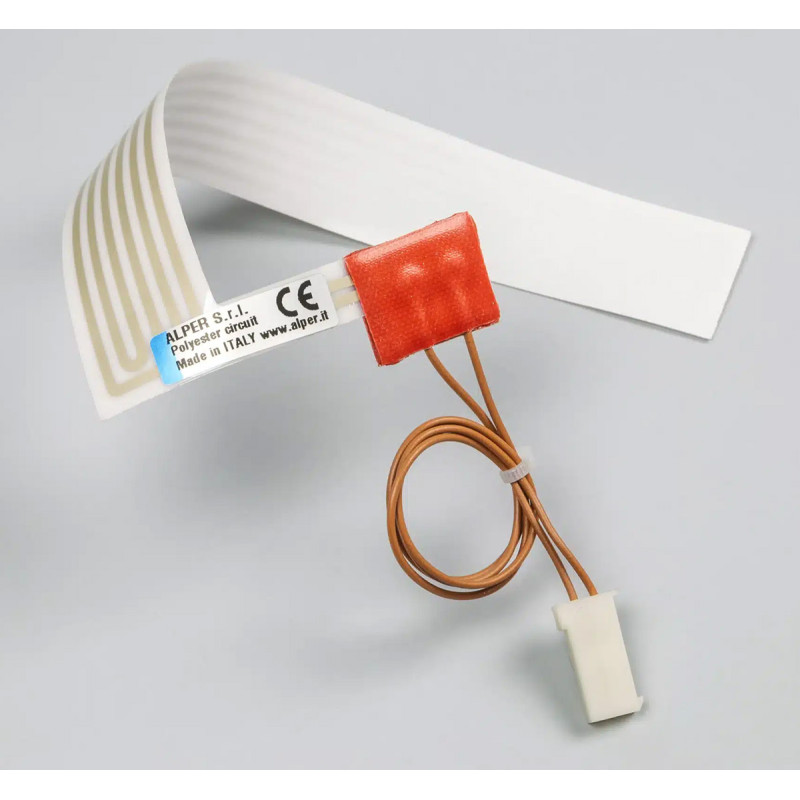

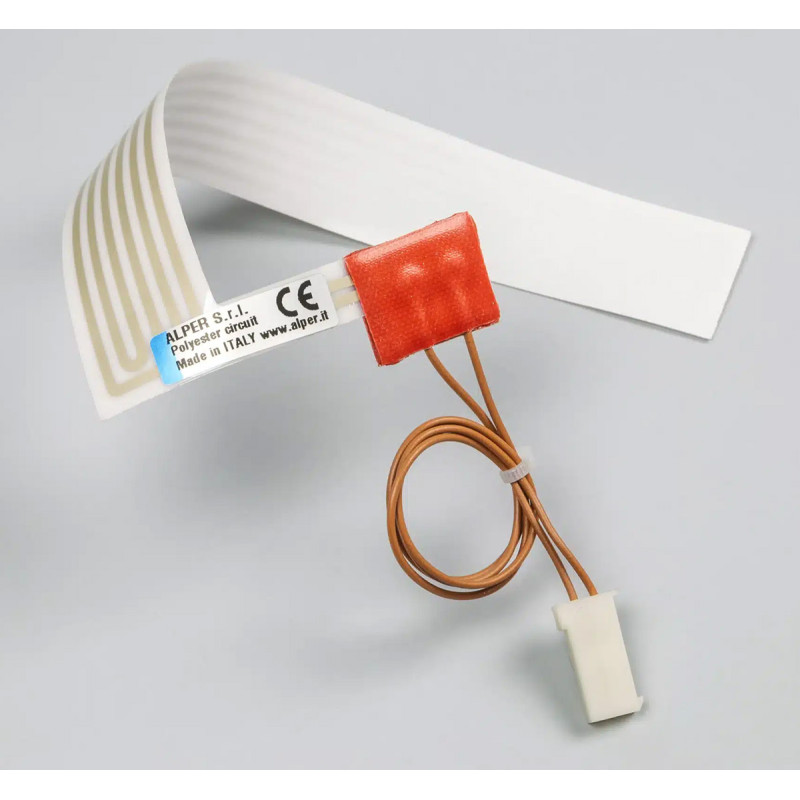

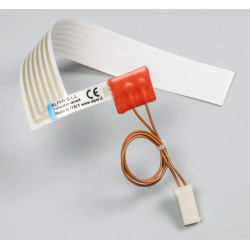

Conductive traces are applied using a compound based on silver and other components. The flexible circuits are then protected by insulating layers that provide high dielectric strength exceeding 3750 V. Each PTF (Polymer Thick Film) flexible circuit can be self-adhesive on one or both sides and equipped with any type of cable and connector.

Flexible printed circuits (FPCs) are exceptionally thin (minimum thickness 0.2 mm) and can bend and flex without risk of breakage or damage to the circuit. Alper's flexible printed circuit boards, manufactured by Printed Electronics, are designed to integrate multiple technologies and implementations in numerous applications.

Thanks to these features, they are used in small spaces where signal and even current are required.

Alper uses Printed Electronics to produce electrical printed circuits using screen printing: a conductive silver paste is applied to a PET sheet. Alper's flexible printed circuits can adapt to any surface without the risk of signal interruption. Polyester film is an ideal flexible substrate; it can be bent without damaging the silver circuit printed on top. The advantage of using Printed Electronics is the ability to create flexible printed circuits suitable for integration with IoT (Internet of Things) technology. Alper's polyester printed circuits are becoming the ultimate tool for intelligent connectivity for exchanging information and processing data between devices.

Érdekel ez a termék? További információra vagy egyedi árajánlatra van szüksége?

Musisz być zalogowany/a

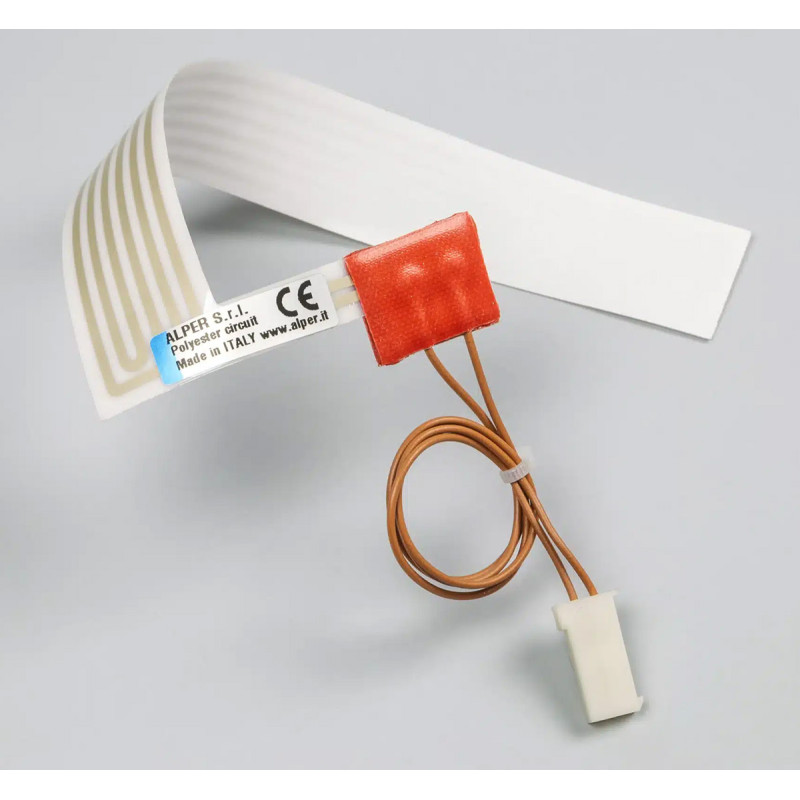

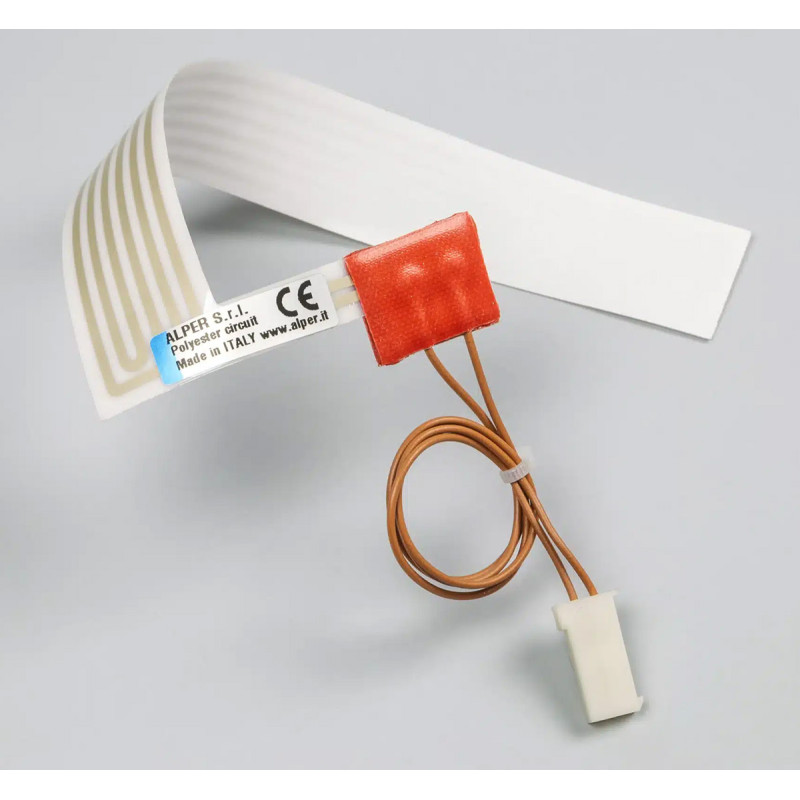

Conductive traces are applied using a compound based on silver and other components. The flexible circuits are then protected by insulating layers that provide high dielectric strength exceeding 3750 V. Each PTF (Polymer Thick Film) flexible circuit can be self-adhesive on one or both sides and equipped with any type of cable and connector.

Flexible printed circuits (FPCs) are exceptionally thin (minimum thickness 0.2 mm) and can bend and flex without risk of breakage or damage to the circuit. Alper's flexible printed circuit boards, manufactured by Printed Electronics, are designed to integrate multiple technologies and implementations in numerous applications.

Thanks to these features, they are used in small spaces where signal and even current are required.

Alper uses Printed Electronics to produce electrical printed circuits using screen printing: a conductive silver paste is applied to a PET sheet. Alper's flexible printed circuits can adapt to any surface without the risk of signal interruption. Polyester film is an ideal flexible substrate; it can be bent without damaging the silver circuit printed on top. The advantage of using Printed Electronics is the ability to create flexible printed circuits suitable for integration with IoT (Internet of Things) technology. Alper's polyester printed circuits are becoming the ultimate tool for intelligent connectivity for exchanging information and processing data between devices.

Olajteknő fűtés – miért védi a kompresszorokat

Olajteknő fűtés – miért védi a kompresszorokat

Nyomtatott elektronika

Nyomtatott elektronika

A megfogalmazott véleményedet nem lehet elküldeni

Hozzászólás jelentése

Jelentés elküldve

Jelentésed beküldése nem lehetséges

Írd meg véleményedet

Vélemény elküldve

Véleményed nem lehet elküldeni