Морате бити пријављени да

-

moreX

-

Компоненте

-

-

Category

-

Полупроводници

- диоде

- Тиристори

-

Електро изоловани модули

- Електро изоловани модули | ВИСХАИ (ИР)

- Електро изоловани модули | ИНФИНЕОН (ЕУПЕЦ)

- Електро изоловани модули | Семикрон

- Електро изоловани модули | ПОВЕРЕКС

- Електро изоловани модули | ИКСИС

- Електро изоловани модули | ПОСЕИЦО

- Електро изоловани модули | АББ

- Електро изоловани модули | ТЕЦХСЕМ

- Go to the subcategory

- Мостовни исправљачи

-

Транзистори

- Транзистори | GeneSiC

- SiC MOSFET модули | Mitsubishi

- SiC MOSFET модули | STARPOWER

- АББ СиЦ МОСФЕТ модули

- IGBT модули | MITSUBISHI

- Транзисторски модули | MITSUBISHI

- MOSFET модули | MITSUBISHI

- Транзисторски модули | ABB

- ИГБТ модули | POWEREX

- ИГБТ модули | ИНФИНЕОН (ЕУПЕЦ)

- Silicijum-karbidni poluprovodnički elementi

- Go to the subcategory

- Гате Дриверс

- Блокови напајања

- Go to the subcategory

- Električni pretvarači

-

Пасивне компоненте (кондензатори, отпорници, осигурачи, филтери)

- Otpornici

-

Osigurači

- Minijaturni osigurači za elektronske sisteme serije ABC i AGC

- Cilindrični brzi osigurači

- Osigurači sa odloženim delovanjem GL/GG i AM karakteristika

- Ultra-brzi osigurači

- Brzi osigurači sa britanskim i američkim standardom

- Brzi osigurači sa evropskim standardom

- Vučni osigurači

- Visokonaponski osigurači

- Go to the subcategory

-

Kondenzatori

- Motorni kondenzatori

- Elektrolitski kondenzatori

- Kondenzatori - snubberi

- Energetski kondenzatori

- Kondenzatori za DC kola

- kondenzatori za kompenzaciju snage

- Visokonaponski kondenzatori

- Kondenzatori za indukciono grejanje

- Impulsni kondenzatori

- ДЦ ЛИНК кондензатори

- Кондензатори за АЦ/ДЦ кола

- Go to the subcategory

- EMI filtri

- Superkondenzatori

- Заштита од пренапона

- TEMPEST филтери за откривање емисије

- Одводник пренапона

- Go to the subcategory

-

Releji i kontaktori

- Теорија релеја и склопника

- Trofazni poluprovodnički releji

- Трофазни полупроводнички релеји наизменичне струје

- Регулатори, команде и додаци

- Sistemi za meki sart i reverziblni kontaktori

- Elektromehanički releji

- Kontaktori

- Rotacioni prekidači

-

Једнофазни полупроводнички релеји наизменичне струје

- Једнофазни релеји наизменичне струје, 1 серија | Д2425 | Д2450

- Jednofazni poluvodički izmjenični releji CWA i CWD serije

- Jednofazni poluvodički izmjenični releji CMRA i CMRD serije

- Jednofazni poluvodički izmjenični releji - serija PS

- Двоструки и четвороструки полупроводнички релеји наизменичне струје, серије Д24 Д, ТД24 К, Х12Д48 Д.

- Jednofazni poluvodički releji - gn serije

- Jednofazni kružni releji Ckr serije

- Jednofazni AC poluvodički releji za DIN sabirnice - ERDA I ERAA serija

- 150A AC jednofazni releji

- Čvrsti releji s ugrađenim hladnjakom na šini - ENDA, ERDA1 / ERAA1 series

- Go to the subcategory

- Monofazni poluprovodnički releji za štampane ploče

- Интерфејс релеји

- Go to the subcategory

- Indukcione komponenete

- Radijatori, Varistori, Termička zaštita

- Ventilatori

- Klimatizacija, Pribor za industrijska kućišta, Kuleri

-

Батерије, пуњачи, бафер напајања и претварачи

- Батерије, пуњачи - теоријски опис

- Litijum-jonske baterije. Nestandardne baterije. Sistem za upravljanje baterijom (BMS)

- Baterije

- Punjači i dodaci za baterije

- UPS i puferski izvori napajanja

- Pretvarači i dodaci- fotonaponski

- Складиште енергије

- Гориве ћелије

- Литијум-јонске батерије

- Go to the subcategory

- Automatika

-

Kablovi, Licnaste žice, Kablovski kanali, Fleksibilne veze

- жице

- Кабловски уводи и спојнице

- лицнастим жице

-

Каблови за специјалне намене

- Продужни каблови и компензацијом

- Каблови за термопарова

- Прикључни жице за цзијнков ПТ

- Мултицоре цаблес темп. -60 ° Ц до + 1400 ° Ц

- СИЛИЦОУЛ средње каблови

- Игнитион жице

- грејни каблови

- Сингле цоре темп. -60 ° Ц до + 450 ° Ц

- траин проводници

- Грејни каблови у Ек

- Каблови за одбрамбену индустрију

- Go to the subcategory

- схиртс

-

плетенице

- браидс флат

- плетенице коло

- Врло флексибилан плетеница - стан

- Врло флексибилан плетеница - коло

- Бакар плетена цилиндрични

- Бакра плетеница штит и цилиндрични

- Флексибилни уземљење траке

- ПВЦ изолацијом бакарне плетенице - Температура 85 ° Ц

- Стан плетени алуминијум

- Цоннецтион Кит - плетенице и цеви

- челичне плетенице

- Go to the subcategory

- Прибор за вучу

- папучица

- Флексибилни исолатед сабирнице

- Вишеслојна флексибилан шина

- системи за управљање кабл

- Go to the subcategory

- View all categories

-

Полупроводници

-

-

- Suppliers

-

Applications

- Automatika industrijska

- CNC alatni strojevi

- DC i izmjenični pogoni (pretvarači)

- Energy bank

- Indukciono grejanje

- Industrijski zaštitni uređaji

- Istraživanje i laboratorijska merenja

- Mašine za sušenje i obradu drveta

- Mašine za termoformiranje

- Merenje i regulacija temperature

- Motori i transformatori

- Oprema i dijelovi za opasna područja (EX)

- Oprema za centrale, kontrolne ormare i telekomunikacije

- Poligrafija

- Rudarstvo, metalurgija i livnica

- Tramvajska i železnička vuča

- UPS i ispravljački sistemi

- Апарати за заваривање и апарати за заваривање

- Индустријска аутоматизација

- ХВАЦ аутоматизација

-

Инсталација

-

-

Индуктори

-

-

Индукциони уређаји

-

-

Услуга

-

- Kontakt

- Zobacz wszystkie kategorie

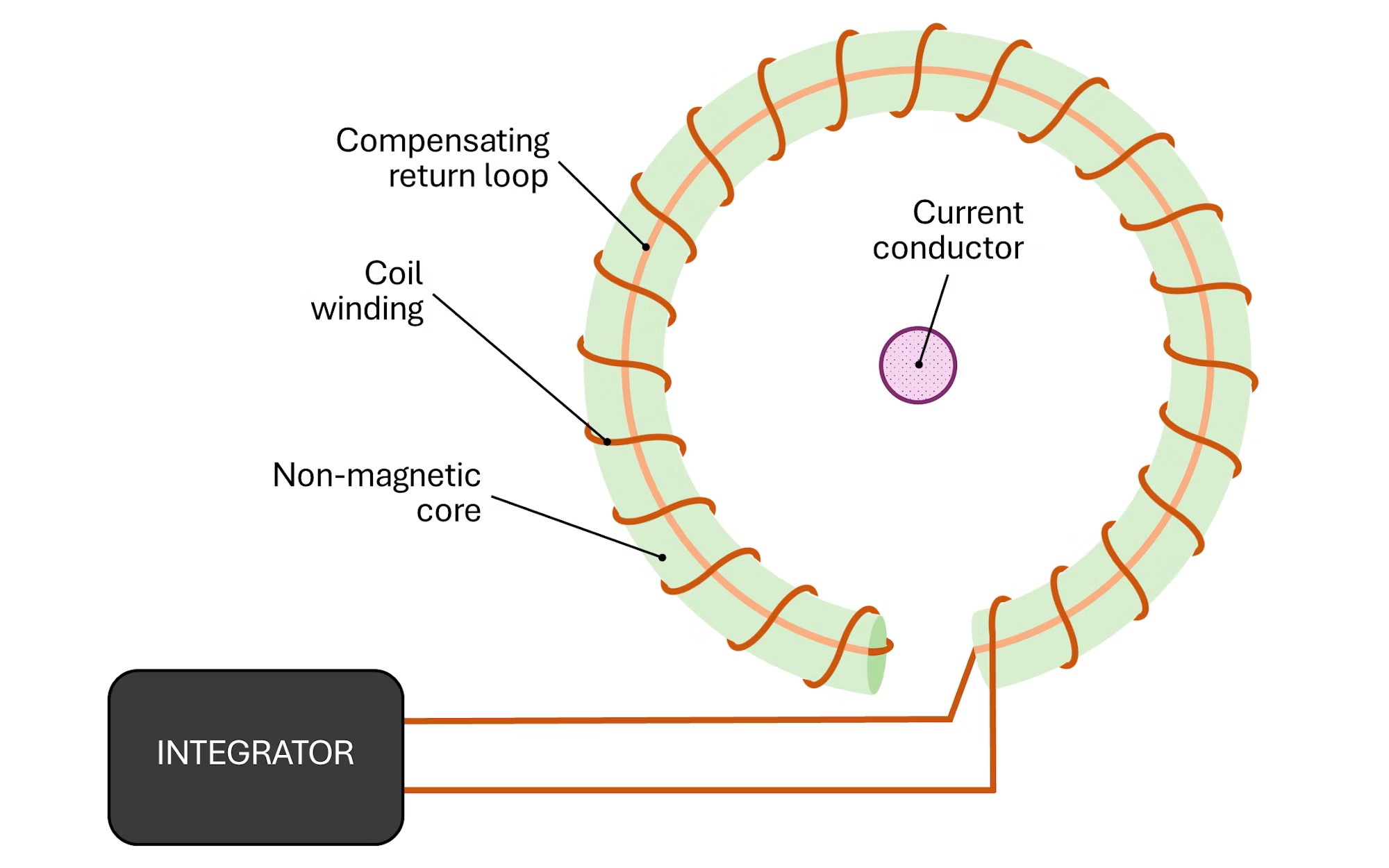

Rogovski kalemovi – konstrukcija i princip rada

Rogowski coils, thanks to their coreless design and wide frequency range, are becoming an increasingly popular alternative to traditional transformers or Hall sensors. In this article, we present the principle of their operation, practical applications, and compare them with other measurement technologies.

What is a Rogowski coil?

A Rogowski coil is a coreless current transducer used for measuring alternating current (AC). It operates based on the principle of electromagnetic induction – it measures the changing magnetic flux generated by the current flow, inducing a voltage proportional to the rate of change of current over time (dI/dt).

Applications of Rogowski coils

Rogowski coils are widely used in:

- power engineering (network monitoring, power quality analysis),

- industrial automation (drive control, motor startup),

- measuring devices and power parameter recorders,

- renewable energy installations (PV, wind turbines),

- e-mobility (charger monitoring, EV infrastructure),

- scientific research and laboratory pulsed current measurements.

Construction of a Rogowski coil

The coil consists of a flexible copper winding spirally wound around a plastic (non-ferromagnetic) core, shaped as a ring or an open loop. It has no ferromagnetic core, eliminating the problems of saturation and hysteresis.

Operating principle of a Rogowski coil

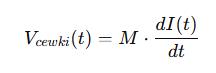

The Rogowski coil works according to Faraday's law of induction: a changing magnetic field, caused by the current flow in the conductor surrounded by the coil, induces a voltage in it. This voltage is proportional to the derivative of the current over time:

*where M is the mutual inductance of the coil relative to the conductor.

To obtain the instantaneous current value, the signal from the coil must be integrated in the measurement path (either analog or digital). Key phenomena used in operation:

- electromagnetic induction (Faraday's law),

- superposition principle (for multi-conductor measurement systems),

- no magnetic coupling with a core (no saturation effect).

Why are PEM coils market leaders?

Rogowski coils from PEM (Power Electronic Measurements Ltd) are considered among the most accurate and stable solutions on the market. The company has been specializing exclusively in Rogowski coil technology for over 30 years, developing a range of innovative solutions:

RCT – industrial Rogowski coils for network monitoring

The RCT series is designed for operation in industrial environments. It offers:

- compliance with industrial standards,

- DIN rail mounting (easy integration with switchgear),

- digital communication via Modbus RTU interface, enabling remote parameter monitoring.

CWT – broadband coils for laboratory and power electronics applications

The CWT series includes precise probes with a wide frequency range – from low to very high:

- available in LF (Low Frequency) and HF (High Frequency) variants,

- bandwidth up to 30 MHz,

- option to choose between external or integrated integrator circuits.

CWT Mini / CWT UltraMini – miniature probes for local measurements

Designed for the most demanding and compact systems, the CWT Mini and UltraMini probes allow for:

- innovative measurement of through-hole components (THT),

- safe and precise measurements of semiconductor circuits (e.g., MOSFET, IGBT, SiC, GaN),

- installation in very limited spaces – e.g., directly on PCBs.

Why choose PEM coils?

PEM solutions stand out from the competition due to their unique design features and quality of workmanship:

- Measurement accuracy up to ±0.1%, achieved through individual calibration of each coil.

- No ferromagnetic core, eliminating issues of magnetic saturation and hysteresis.

- Wide frequency bandwidth – up to 30 MHz, depending on the model.

- Current measurement from a few milliamperes to hundreds of kiloamperes, including pulsed and high-frequency disturbances (HF).

- Flexible mechanical design – coils are lightweight, bendable, often with an openable structure.

- Compliance with international standards, including IEC 61010 and IEC 61869, ensuring safety and reliability.

Comparison with other current measurement methods

In engineering practice, various technologies are used for current measurement, each with its strengths and limitations. The Rogowski coil stands out due to its unique design and characteristics. Here's how it compares to other solutions:

Rogowski Coil

This is a coreless current transducer ideal for measuring alternating and pulsed currents. Its main advantages include:

- No saturation (because it does not contain a ferromagnetic core),

- Very wide frequency range, even up to tens of megahertz,

- Low weight and flexibility — can be installed even in hard-to-reach places,

- Safe, non-contact measurement (galvanic isolation).

Main limitation: it does not allow for direct measurement of the DC component, and the resulting voltage signal requires integration (analog or digital), which may increase the complexity of the measurement system.

Current Transformer (CT)

This traditional solution is primarily used in power engineering and AC current measurement systems. Main advantages include:

- Simple design and reliability,

- Good accuracy at power line frequencies (50/60 Hz),

- Low cost and wide availability.

Limitations include core saturation at high currents, limited frequency range (typically a few hundred Hz to a few kHz), and larger size and weight.

Shunt (measuring resistor)

A shunt is a precision resistor where the voltage drop is used to calculate the current value. Its advantages include:

- Measurement of both DC and AC,

- Very good accuracy at low currents,

- Direct integration with measurement electronics.

Its drawbacks are that the shunt must be inserted into the current circuit, which means no galvanic isolation, risk of thermal losses, and potential overheating at high currents.

Hall Effect Sensor

Hall sensors use the Hall effect to measure the magnetic field generated by the current, enabling measurement of both DC and AC currents. Additional advantages include:

- Full galvanic isolation,

- Compact form factor,

- Easy integration with digital systems.

Main disadvantages include lower accuracy compared to shunts or Rogowski coils, temperature sensitivity, and limitations in high-frequency signal measurement.

Conclusion

The Rogowski coil is best suited where the following are required:

- Measurement of high currents (pulsed or alternating),

- Wide measurement bandwidth,

- Lightweight, flexible, and non-contact installation,

- No issues with saturation or hysteresis.

However, for DC current measurement, high accuracy at low ranges, or simplicity of the system, other technologies may be more appropriate — each has its place in specific applications.

Rogowski coils are current transducers that, thanks to their coreless design, wide bandwidth, and high mechanical flexibility, are ideal for demanding measurement applications. Their ability to accurately reflect rapidly changing currents, immunity to saturation, and resistance to electromagnetic interference make them an ideal choice for power electronics, industrial automation, scientific research, renewable energy systems, and electromobility.

Although not a universal solution (e.g., they do not directly measure DC current), in many scenarios they outperform traditional current transformers, shunts, or Hall sensors – especially where dynamics, safety, and ease of installation matter most.

The choice of the right current measurement technology should always consider the characteristics of the measured signals and the operating environment — and the Rogowski coil may just be the missing link in a modern measurement system.

Related products

Related posts

Now available – DC/DC converters from PREMIUM

Now available – DC/DC converters from PREMIUM

New release in DACPOL lighting for lathes – Kira covers

New release in DACPOL lighting for lathes – Kira covers

Leave a comment