Debes estar logueado

Category

Las fotos son solo para fines informativos. Ver especificaciones de producto

please use latin characters

The MILEX series case is a waterproof and dustproof, shock- and vibration-absorbing aluminum transit case designed for 19-inch electronics. DACPOL is also able to select subracks for this project, becoming a complete provider of this solution. MILEX products are NATO approved and designed to meet the stringent requirements of U.S. MIL specifications and other MIL standards worldwide. Along with a wide range of accessories such as cooling systems, racks, drawers, and guides, MILEX aluminum cases represent the most comprehensive line currently available for secure packaging of mobile electronics. MILEX transport cases are made exactly to customer specifications. DESAPRO has developed unique experience in custom design and manufacturing to deliver the right quality on time for the specific application.

19” MILEX Series Aluminum Transport Cases meet the rigorous requirements of the MIL-STD-810G standard and other relevant military standards for this type of product. The 19” MILEX Series Transport Cases are designed and manufactured according to specific environmental protection requirements demanded by the equipment contained and transported, ensuring maximum protection while enabling other important and desired features.

The size of the MILEX cases depends on the size of the required equipment. However, thanks to the placement of the handles, the space between the internal housing and the external shell is minimized while maintaining equal or better shock and vibration properties. This feature means that the total dimension of the MILEX housing is as small as possible without sacrificing protective properties.

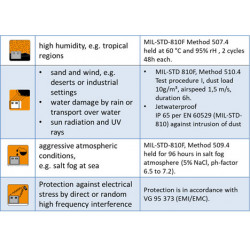

Protection against external conditions:

Undesirable influences from various sources occurring during transport, storage, or operation can have a harmful effect on the device and therefore pose a significant risk. This risk can be minimized by using DESAPRO cases. DESAPRO cases protect against many environmental factors:

Protection against electrical radiation from direct or incidental high-frequency interference:

Solutions for internal equipment issues:

Protection against electrical loads such as electromagnetic interference (EMI), RFI.

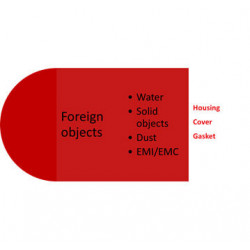

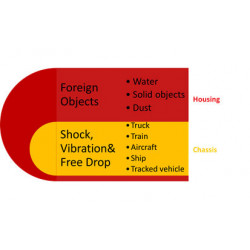

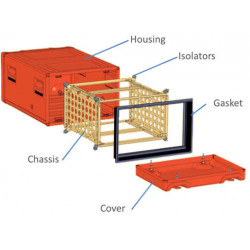

The MILEX aluminum transport case essentially consists of three main parts:

Self-supporting enclosure

Welded and rigid construction creates a self-supporting enclosure that is both lightweight and durable. The entire aluminum structure is shock-resistant and withstands extreme temperature changes, conducts electricity, and is fully recyclable. Stackable feet on the bottom and recesses on the top of the enclosure ensure stable stacking of cases. As standard, cases are equipped with a pressure equalization valve. Enclosure joints and fastening to any screw pattern are available for specific applications.

Shock-absorbing housing

The core of the transport case is a chassis mounted on shock absorbers. Depending on the model and size, the equipment can be mounted at the front or rear of the case. To maintain low weight and allow optimal ventilation, the housings are designed with large openings. The rack is connected to the housing with an electrical grounding strap.

Lid

All MILEX enclosures are protected against external factors with a screw-on lid with a gasket. Easy-to-use closures are recessed into the lid and provide a solid seal. The lid space can be used for an I/O panel, windows, cable glands, ventilation louvers, etc.

There are four types of MILEX housings in 19" technology

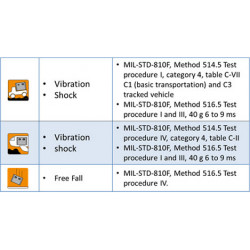

MILEX 19'' transport cases are intended for use in extreme conditions. Electronics are attached to the shock-absorbing housing, not directly to the rack. A minimum of 8 shock and vibration absorbers are used to dampen all mechanical stresses on the housing. Once the housing is mounted, it is tightly closed with a lid to protect the interior from dust, sand, and water.

MILEX transport cases in the Hard Mounted version lack the housing mounted on absorbers. It is intended for applications where vibration protection is not critical. All other protective features and external dimensions are equivalent to the case mounted on shock absorbers.

The frame is mounted on wire rope shock absorbers. These types of shock absorbers are used where electronics must be protected from vibrations and particularly strong shocks. These absorbers provide the necessary deflection that is not provided by standard absorbers in transport cases. Typical applications include shock protection on ships, submarines, helicopters, and other aircraft.

MILEXPRO is the latest generation of rugged cases for transporting sensitive electronics, IT, and measurement systems. It combines high value through reduced integration time and easy access during transport and/or operations. The locking system is unique and supported by a rotating frame system guided in the X and Y axis, automatically centralizing the lid. The long-standing original MILEX features are retained, allowing stacking with other MILEX cases.

Main advantages of MILEXPRO include:

During operation, the user is equipped with maximum protection thanks to the fundamentally improved case design, which provides even better shock and vibration protection. Individual selection of shock mountings allows for universal use of MILEXPRO. The shock mountings can be easily changed later if different equipment is installed in the housing, thanks to profiled mounting support plates. Thanks to the separate sealing and HF shielding system, environmental protection is always ensured, and HF shielding can optionally be added later if needed.

Cost savings Significant reduction in integration time, and thus cost savings, is possible due to the complete removal of the internal rack. The ability to separate the housing body and rack further helps to avoid scratching the housing during the integration phase. With free access to the rack, optimal cable management is ensured. Time savings due to clean and efficient integration management are possible. Flexibility thanks to the variety of MILEX options. We offer customized aluminum transport case options to meet specific requirements and needs.

A wide selection of standard accessories is available:

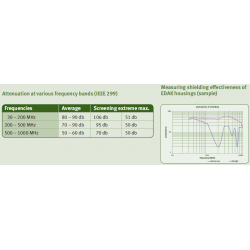

EMI and RFI SHIELDING OPTIONS EMI Gasket Electrically conductive gasket mounted in the housing to provide electrical contact between the covers and the housing. This gasket also protects the housing from atmospheric influences when the covers are mounted. Conductive EMI filler gasket To eliminate the risk of contaminating the interior of the housing with water or dust after removing the covers, a flexible gasket can be specified and mounted between the housing and the rack. This flexible gasket does not affect the vibration characteristics of the housing. Sealing the space between the housing and the frame results in IP 65 protection. The floor gasket conducts electric current. EMC Frame A special EMI frame made of chromated aluminum can be used for additional EMI protection. This provides maximum protection for the electronics inside the housing. To dissipate the heat generated by the electronics, the frame walls have 3 mm diameter holes, with an average distance between holes of 4 mm.

Properties and characteristics

Diverse range of standard sizes (DIN41494 / IEC297)

The performance of MILEX enclosures depends on many variables such as: load weight, load center of gravity, load fragility, load mounting, test duration, test sequence, positive/negative test result criteria, and many other parameters.

Please contact DACPOL to customize the enclosure to qualification requirements.

¿Estás interesado en este producto? ¿Necesita información adicional o precios individuales?

Usted debe estar conectado

The MILEX series case is a waterproof and dustproof, shock- and vibration-absorbing aluminum transit case designed for 19-inch electronics. DACPOL is also able to select subracks for this project, becoming a complete provider of this solution. MILEX products are NATO approved and designed to meet the stringent requirements of U.S. MIL specifications and other MIL standards worldwide. Along with a wide range of accessories such as cooling systems, racks, drawers, and guides, MILEX aluminum cases represent the most comprehensive line currently available for secure packaging of mobile electronics. MILEX transport cases are made exactly to customer specifications. DESAPRO has developed unique experience in custom design and manufacturing to deliver the right quality on time for the specific application.

19” MILEX Series Aluminum Transport Cases meet the rigorous requirements of the MIL-STD-810G standard and other relevant military standards for this type of product. The 19” MILEX Series Transport Cases are designed and manufactured according to specific environmental protection requirements demanded by the equipment contained and transported, ensuring maximum protection while enabling other important and desired features.

The size of the MILEX cases depends on the size of the required equipment. However, thanks to the placement of the handles, the space between the internal housing and the external shell is minimized while maintaining equal or better shock and vibration properties. This feature means that the total dimension of the MILEX housing is as small as possible without sacrificing protective properties.

Protection against external conditions:

Undesirable influences from various sources occurring during transport, storage, or operation can have a harmful effect on the device and therefore pose a significant risk. This risk can be minimized by using DESAPRO cases. DESAPRO cases protect against many environmental factors:

Protection against electrical radiation from direct or incidental high-frequency interference:

Solutions for internal equipment issues:

Protection against electrical loads such as electromagnetic interference (EMI), RFI.

The MILEX aluminum transport case essentially consists of three main parts:

Self-supporting enclosure

Welded and rigid construction creates a self-supporting enclosure that is both lightweight and durable. The entire aluminum structure is shock-resistant and withstands extreme temperature changes, conducts electricity, and is fully recyclable. Stackable feet on the bottom and recesses on the top of the enclosure ensure stable stacking of cases. As standard, cases are equipped with a pressure equalization valve. Enclosure joints and fastening to any screw pattern are available for specific applications.

Shock-absorbing housing

The core of the transport case is a chassis mounted on shock absorbers. Depending on the model and size, the equipment can be mounted at the front or rear of the case. To maintain low weight and allow optimal ventilation, the housings are designed with large openings. The rack is connected to the housing with an electrical grounding strap.

Lid

All MILEX enclosures are protected against external factors with a screw-on lid with a gasket. Easy-to-use closures are recessed into the lid and provide a solid seal. The lid space can be used for an I/O panel, windows, cable glands, ventilation louvers, etc.

There are four types of MILEX housings in 19" technology

MILEX 19'' transport cases are intended for use in extreme conditions. Electronics are attached to the shock-absorbing housing, not directly to the rack. A minimum of 8 shock and vibration absorbers are used to dampen all mechanical stresses on the housing. Once the housing is mounted, it is tightly closed with a lid to protect the interior from dust, sand, and water.

MILEX transport cases in the Hard Mounted version lack the housing mounted on absorbers. It is intended for applications where vibration protection is not critical. All other protective features and external dimensions are equivalent to the case mounted on shock absorbers.

The frame is mounted on wire rope shock absorbers. These types of shock absorbers are used where electronics must be protected from vibrations and particularly strong shocks. These absorbers provide the necessary deflection that is not provided by standard absorbers in transport cases. Typical applications include shock protection on ships, submarines, helicopters, and other aircraft.

MILEXPRO is the latest generation of rugged cases for transporting sensitive electronics, IT, and measurement systems. It combines high value through reduced integration time and easy access during transport and/or operations. The locking system is unique and supported by a rotating frame system guided in the X and Y axis, automatically centralizing the lid. The long-standing original MILEX features are retained, allowing stacking with other MILEX cases.

Main advantages of MILEXPRO include:

During operation, the user is equipped with maximum protection thanks to the fundamentally improved case design, which provides even better shock and vibration protection. Individual selection of shock mountings allows for universal use of MILEXPRO. The shock mountings can be easily changed later if different equipment is installed in the housing, thanks to profiled mounting support plates. Thanks to the separate sealing and HF shielding system, environmental protection is always ensured, and HF shielding can optionally be added later if needed.

Cost savings Significant reduction in integration time, and thus cost savings, is possible due to the complete removal of the internal rack. The ability to separate the housing body and rack further helps to avoid scratching the housing during the integration phase. With free access to the rack, optimal cable management is ensured. Time savings due to clean and efficient integration management are possible. Flexibility thanks to the variety of MILEX options. We offer customized aluminum transport case options to meet specific requirements and needs.

A wide selection of standard accessories is available:

EMI and RFI SHIELDING OPTIONS EMI Gasket Electrically conductive gasket mounted in the housing to provide electrical contact between the covers and the housing. This gasket also protects the housing from atmospheric influences when the covers are mounted. Conductive EMI filler gasket To eliminate the risk of contaminating the interior of the housing with water or dust after removing the covers, a flexible gasket can be specified and mounted between the housing and the rack. This flexible gasket does not affect the vibration characteristics of the housing. Sealing the space between the housing and the frame results in IP 65 protection. The floor gasket conducts electric current. EMC Frame A special EMI frame made of chromated aluminum can be used for additional EMI protection. This provides maximum protection for the electronics inside the housing. To dissipate the heat generated by the electronics, the frame walls have 3 mm diameter holes, with an average distance between holes of 4 mm.

Properties and characteristics

Diverse range of standard sizes (DIN41494 / IEC297)

The performance of MILEX enclosures depends on many variables such as: load weight, load center of gravity, load fragility, load mounting, test duration, test sequence, positive/negative test result criteria, and many other parameters.

Please contact DACPOL to customize the enclosure to qualification requirements.

New transport crates 19” from DESAPRO - MILEX series

New transport crates 19” from DESAPRO - MILEX series

STANEX transport cases

STANEX transport cases

¿Cómo cuidar las maletas y cajas de transporte para que duren años?

¿Cómo cuidar las maletas y cajas de transporte para que duren años?

Su agradecimiento a la reseña no pudo ser enviado

Reportar comentario

Reporte enviado

Su reporte no pudo ser enviado

Escriba su propia reseña

Reseña enviada

Su reseña no pudo ser enviada