Sie müssen eingeloggt sein

Category

Fotos dienen nur zu Informationszwecken.

please use latin characters

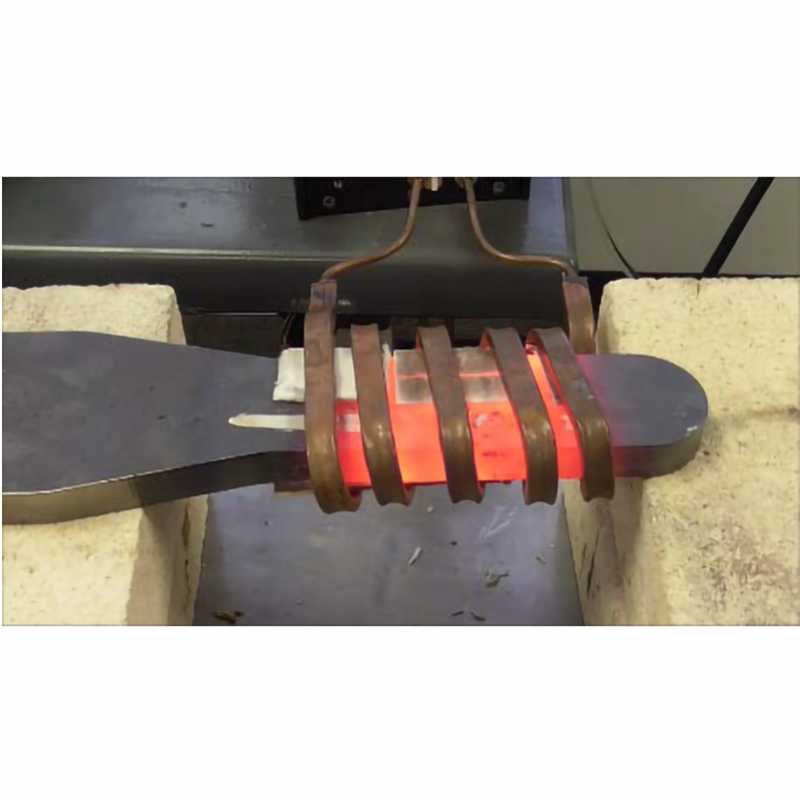

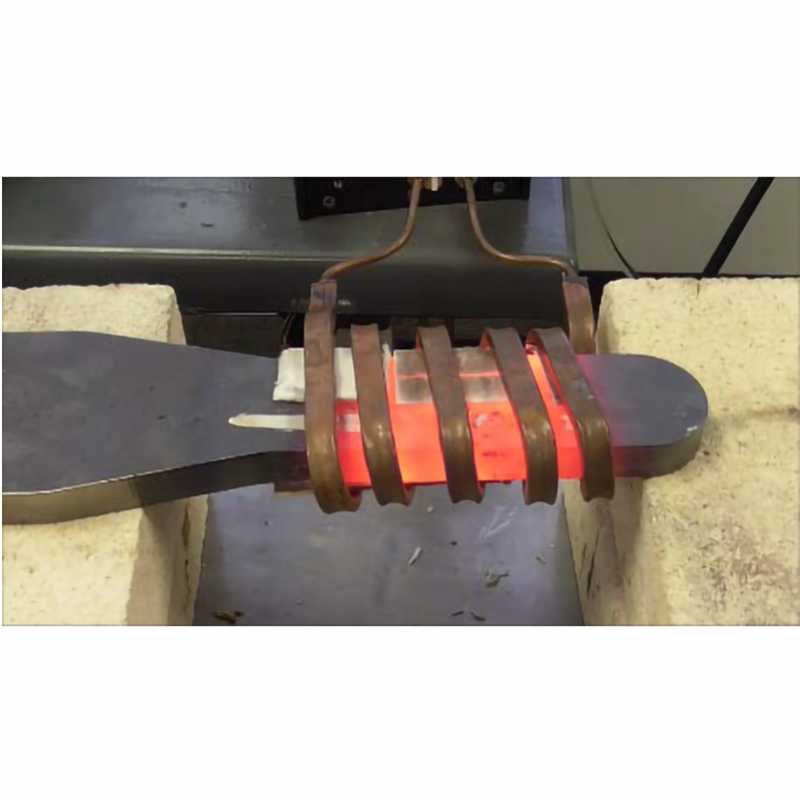

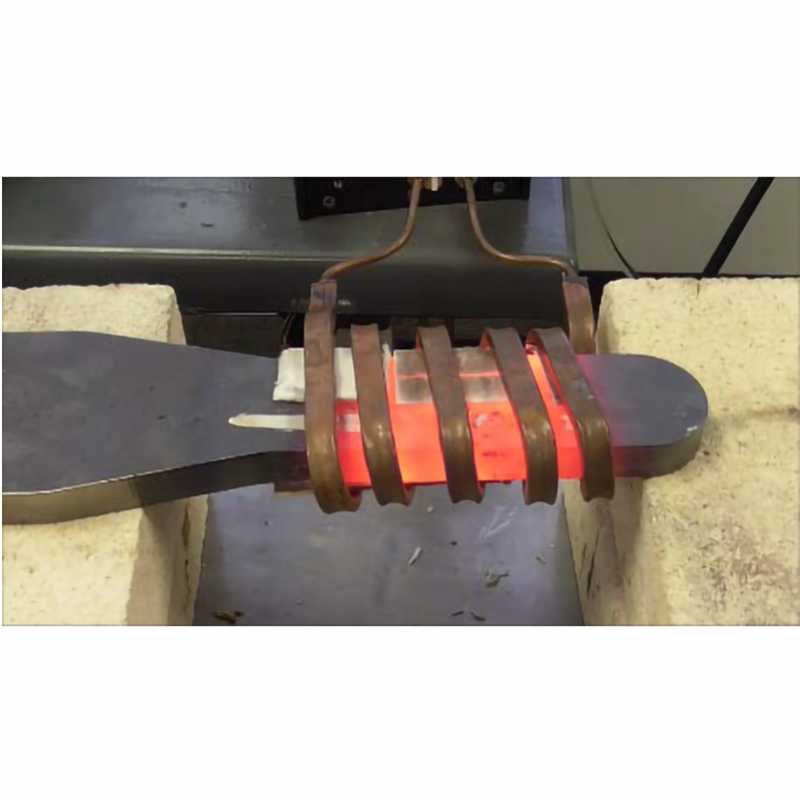

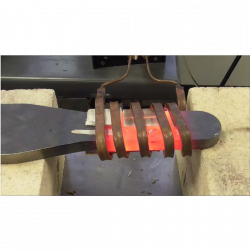

Objective: To heat a magnetic steel part for a forming application; the client had been using a torch for the application.

Frequency: 125 kHz

Material: Magnetic steel part

Temperature: 1700 °F (927 °C)

Temperature indicating paint was applied to the part to easily identify when it achieved temperature, and then the induction power was turned on. It took about three minutes for the part to reach 1700 °F (927 °C) at 10 kW and two minutes and twenty seconds with 15 kW for this through-Curie heating application.

Interessieren Sie sich für dieses Produkt? Benötigen Sie zusätzliche Informationen oder individuelle Preise?

Sie müssen eingeloggt sein

Objective: To heat a magnetic steel part for a forming application; the client had been using a torch for the application.

Frequency: 125 kHz

Material: Magnetic steel part

Temperature: 1700 °F (927 °C)

Temperature indicating paint was applied to the part to easily identify when it achieved temperature, and then the induction power was turned on. It took about three minutes for the part to reach 1700 °F (927 °C) at 10 kW and two minutes and twenty seconds with 15 kW for this through-Curie heating application.

Ihre Bewertung der Rezension kann nicht gesendet werden

Kommentar melden

Meldung gesendet

Ihre Meldung kann nicht gesendet werden

Eigenen Kommentar verfassen

Bewertung gesendet

Ihre Bewertung kann nicht gesendet werden