Sie müssen eingeloggt sein

Category

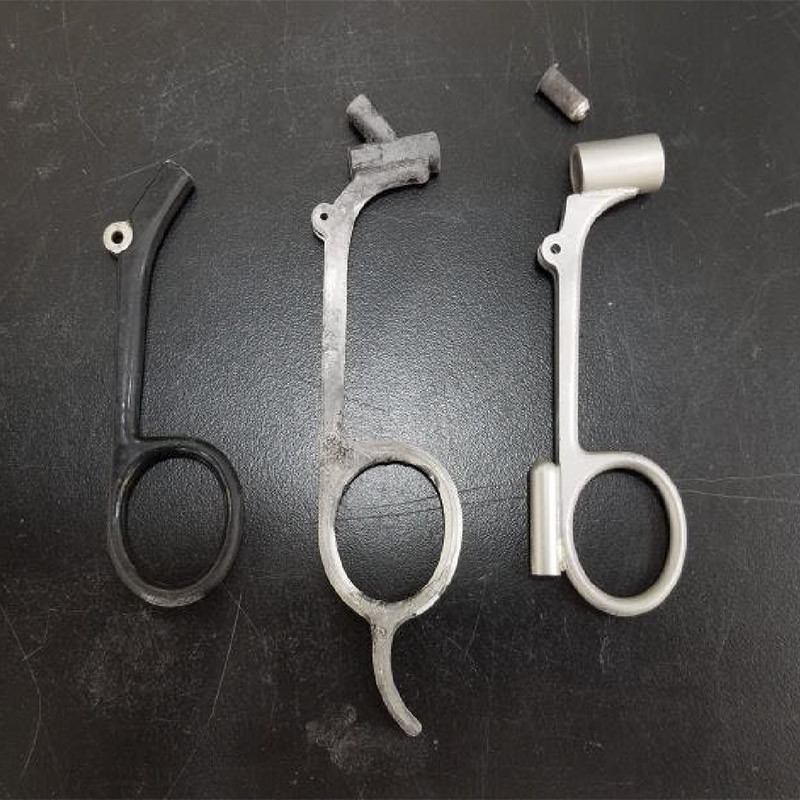

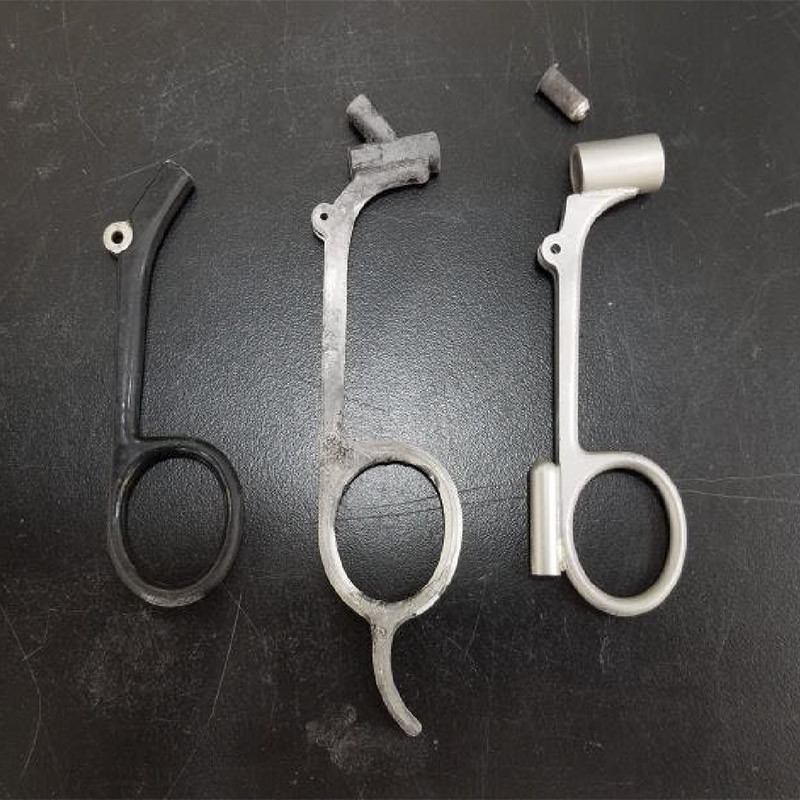

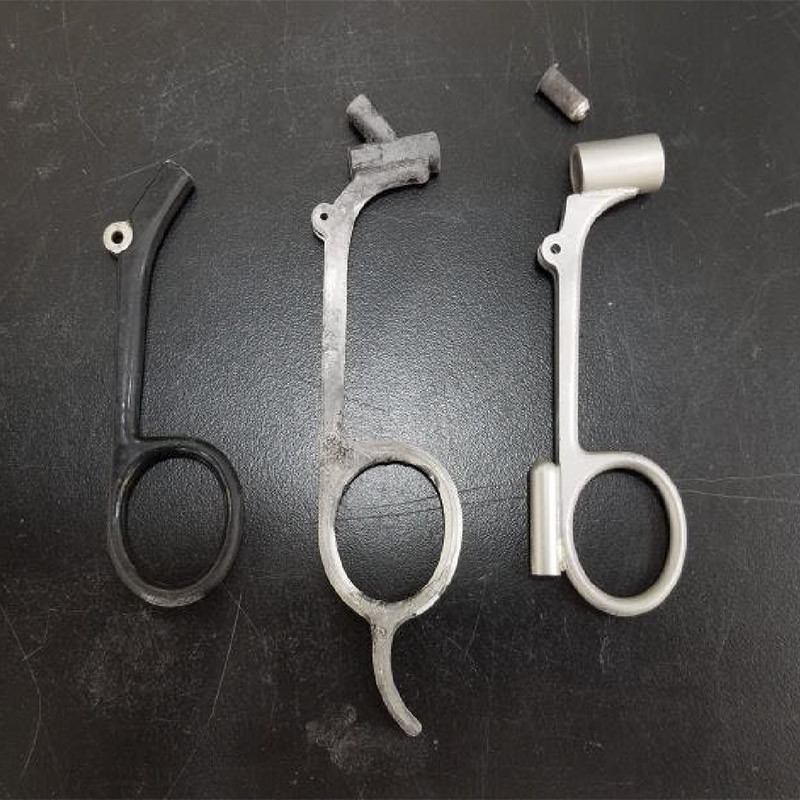

Fotos dienen nur zu Informationszwecken.

please use latin characters

Objective: To heat surgical tools to burn-off the nylon coating; the client had been using a torch for this application.

Equipment: Ambrell EASYHEAT® 1.2 kW, 150-400 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Frequency: 251 kHz

Material: Magnetic steel surgical tools

Testing:

Benefits:

Interessieren Sie sich für dieses Produkt? Benötigen Sie zusätzliche Informationen oder individuelle Preise?

Sie müssen eingeloggt sein

Objective: To heat surgical tools to burn-off the nylon coating; the client had been using a torch for this application.

Equipment: Ambrell EASYHEAT® 1.2 kW, 150-400 kHz induction heating power supply with a workhead and coil specifically designed for this application.

Frequency: 251 kHz

Material: Magnetic steel surgical tools

Testing:

Benefits:

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Eigenen Kommentar verfassen

Review sent

Your review cannot be sent