Sie müssen eingeloggt sein

Category

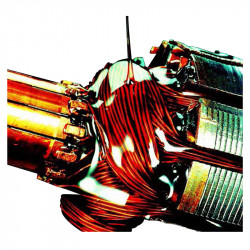

Fotos dienen nur zu Informationszwecken.

please use latin characters

One component material, for electrical insulation class B 130°C

Dry on air.

Application:

- electro technical material class B,

- transformers.

Main preferences

- Impregnation lacquer made from modified alkyd resin, dry fast on air, give good protection film

- resistant for humidity and mineral oils.

- is comptabile with cables in enamel class B, F and H,

- G 159 T (tropical version)satisfy requirements 41514 NFX.

Impregnation:

- by immersion, spray or vacuum.

Polymerisation:

- Few hours in a room temperature. After one hour lacquer is not viscous.

- lacquer preferences are better when it is dried in temperature 80/100°C,

- whenn resistance for diluent or chemicals is needed, it must be dried in temperature 130°C.

Storage conditions:

6 months in original and closed package, far away from the sun and heat source.

Packing

- containers 1, 5, 30 l or 200 barrels and spray.

Hygiene and protection:

Lacquer consists ksylen.

| Lacquer | Standard | G 159 | G 159T |

|---|---|---|---|

| Chemical origins | Modified alkyd | Modified alkyd | |

| Thermal class | (B)/130°C | (B)/130°C | |

| viscosity | ISO 2431 | 60s +/- 20s | 60s +/- 20s |

| density @ 20°C | NFT30020 | 0,95 | 0,95 |

| Ignition point - crucible closed | NFT 30020 | 26°C | 26°C |

| Dry extract | NSEG 0001 | 40% +/- 2 | 40% +/- 2 |

| Colour | Mahoń, pomarańcz. | Mahoń | |

| Drying on a plate | NSEG 0002 | w 23°C 45 min. | w23°C45 min. |

| Diluent | 37022 | 37022 |

| Breakdown on a copper plate [thickness 0,01 mm] | Volt |

|---|---|

| natural state | 1000 |

| After 8 days in humid air: | 850 |

| After 8 days in destilated water: | 800 |

| After 8 days in oil: | 1200 |

Interessieren Sie sich für dieses Produkt? Benötigen Sie zusätzliche Informationen oder individuelle Preise?

Sie müssen eingeloggt sein

One component material, for electrical insulation class B 130°C

Dry on air.

Application:

- electro technical material class B,

- transformers.

Main preferences

- Impregnation lacquer made from modified alkyd resin, dry fast on air, give good protection film

- resistant for humidity and mineral oils.

- is comptabile with cables in enamel class B, F and H,

- G 159 T (tropical version)satisfy requirements 41514 NFX.

Impregnation:

- by immersion, spray or vacuum.

Polymerisation:

- Few hours in a room temperature. After one hour lacquer is not viscous.

- lacquer preferences are better when it is dried in temperature 80/100°C,

- whenn resistance for diluent or chemicals is needed, it must be dried in temperature 130°C.

Storage conditions:

6 months in original and closed package, far away from the sun and heat source.

Packing

- containers 1, 5, 30 l or 200 barrels and spray.

Hygiene and protection:

Lacquer consists ksylen.

| Lacquer | Standard | G 159 | G 159T |

|---|---|---|---|

| Chemical origins | Modified alkyd | Modified alkyd | |

| Thermal class | (B)/130°C | (B)/130°C | |

| viscosity | ISO 2431 | 60s +/- 20s | 60s +/- 20s |

| density @ 20°C | NFT30020 | 0,95 | 0,95 |

| Ignition point - crucible closed | NFT 30020 | 26°C | 26°C |

| Dry extract | NSEG 0001 | 40% +/- 2 | 40% +/- 2 |

| Colour | Mahoń, pomarańcz. | Mahoń | |

| Drying on a plate | NSEG 0002 | w 23°C 45 min. | w23°C45 min. |

| Diluent | 37022 | 37022 |

| Breakdown on a copper plate [thickness 0,01 mm] | Volt |

|---|---|

| natural state | 1000 |

| After 8 days in humid air: | 850 |

| After 8 days in destilated water: | 800 |

| After 8 days in oil: | 1200 |

Ihre Bewertung der Rezension kann nicht gesendet werden

Kommentar melden

Meldung gesendet

Ihre Meldung kann nicht gesendet werden

Eigenen Kommentar verfassen

Bewertung gesendet

Ihre Bewertung kann nicht gesendet werden