Category

Photos are for informational purposes only. View product specification

please use latin characters

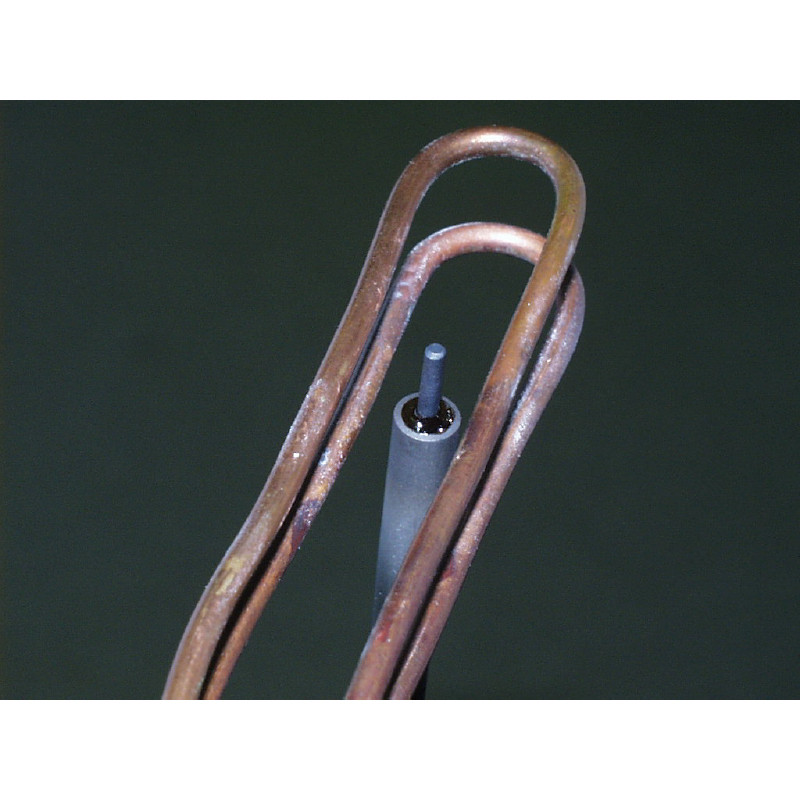

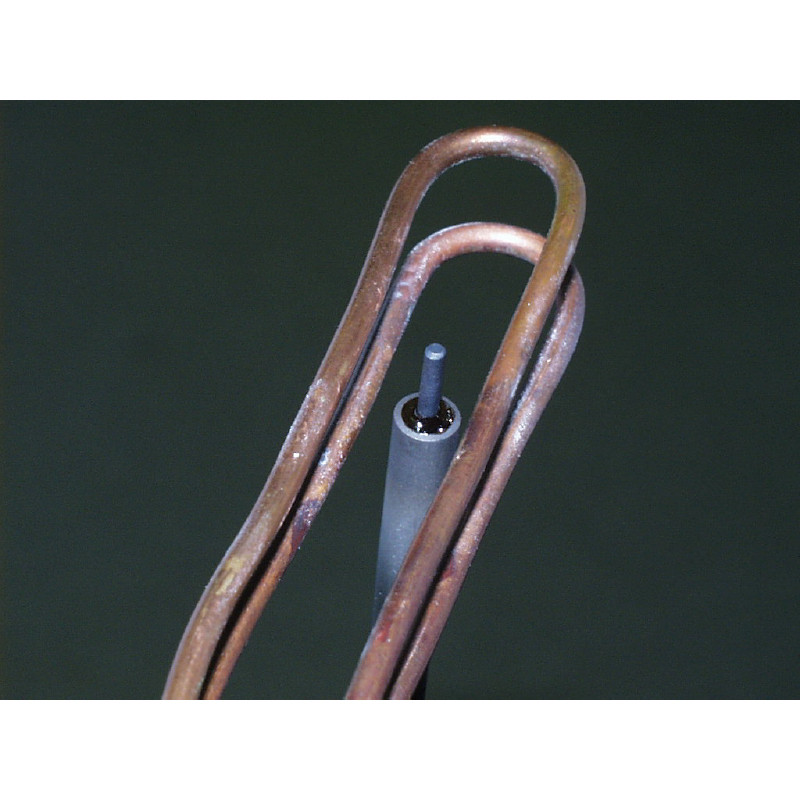

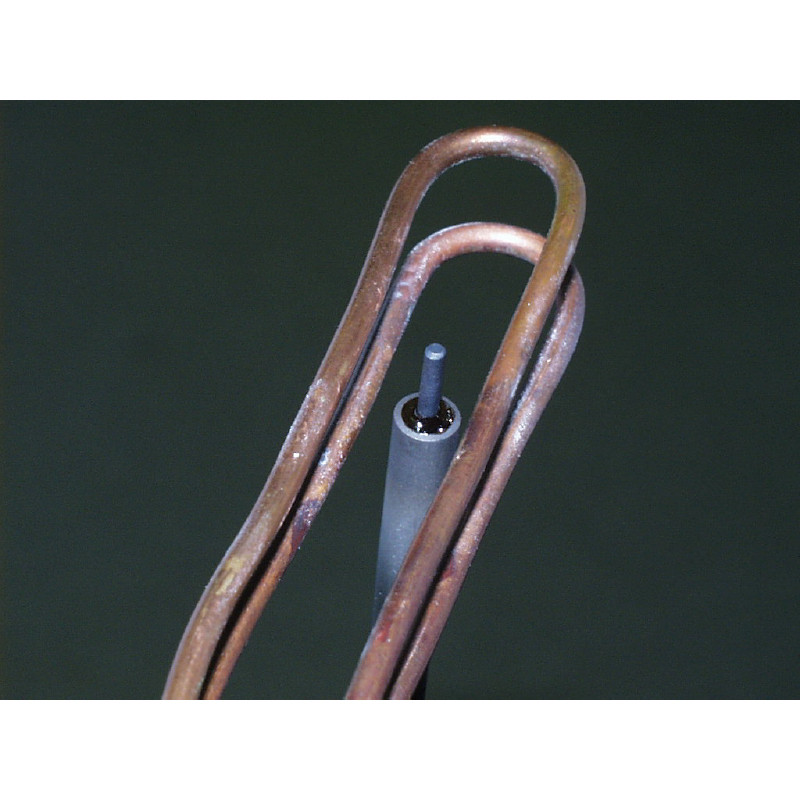

Objective: To heat seal both ends of a stainless steel heater assembly to 300-500 ºF (149-260 ºC) and melt glass preforms.

Frequency: 212 kHz

Material: Stainless steel rods 1/2” to 3” (12.7mm to 76.2mm) diameters, glass preforms.

Temperature: 300-500 °F (149-260 °C)

A two-turn elongated helical coil is used to heat 5 to 7 stainless steel rods simultaneously for 60 seconds. The glass preforms melt and create a hermetic seal. After the first end is heated the parts are repositioned to heat the opposite end.

Are you interested in this product? Do you need additional information or individual pricing?

Objective: To heat seal both ends of a stainless steel heater assembly to 300-500 ºF (149-260 ºC) and melt glass preforms.

Frequency: 212 kHz

Material: Stainless steel rods 1/2” to 3” (12.7mm to 76.2mm) diameters, glass preforms.

Temperature: 300-500 °F (149-260 °C)

A two-turn elongated helical coil is used to heat 5 to 7 stainless steel rods simultaneously for 60 seconds. The glass preforms melt and create a hermetic seal. After the first end is heated the parts are repositioned to heat the opposite end.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent