Litz wires

Categories

| Image | View the product | No. Manufacturer | ||||

|---|---|---|---|---|---|---|

| picture_as_pdf |

|

PACK Litz Wire | Rupalit Safety | SEE IT | -- | On Order |

| picture_as_pdf |

|

PACK Litz Wire | RUPOL SAFETY | SEE IT | -- | On Order |

| picture_as_pdf |

|

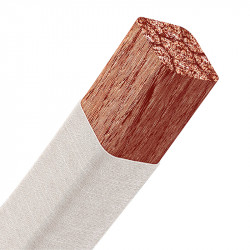

PACK Litz Wire | RUPALIT PROFILE | SEE IT | -- | On Order |

| picture_as_pdf |

|

PACK Litz Wire | Rupalit Planar | SEE IT | -- | On Order |

| picture_as_pdf |

|

PACK Litz Wire | RUPATEX, class B | SEE IT | -- | On Order |

| picture_as_pdf |

|

PACK Litz Wire | Rupalit - Round Lice | SEE IT | -- | On Order |

| -- |

|

PACK Litz Wire | Rupatex, class F | SEE IT | -- | On Order |

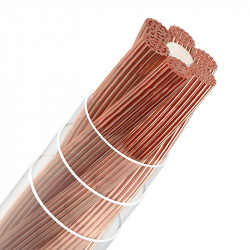

High-frequency litz wire is usually made of many thin insulated copper wires twisted together.

DACPOL offers high-frequency litz wires from PACK Litz Wire. We provide a wide range of copper litz wires with both round and rectangular cross-sections. When using a standard wire is impossible or inefficient, we recommend using litz wire.

Litz wire for high-frequency applications is a conductor made of individually enamel-insulated twisted copper strands.

High-frequency litz wire is used, among others, in transformers and inductive chokes to reduce power losses caused by eddy currents. High-frequency litz wires are used to mitigate the skin effect occurring in a single wire when high current flows through it. The operating frequency determines not only the construction parameters of the litz wire but also defines the diameter of individual strands. The higher the operating frequency of the inductive component, the smaller the diameter of the individual wire. The use of high-frequency litz wire minimizes power losses and significantly reduces winding heating.

High-frequency litz wire - construction: insulated with silk, nylon, or Kapton.

High-Frequency Litz Wire - Skin Effect

When transmitting high-frequency signals (at least several hundred Hz) through conductors, the skin effect occurs. It involves the "pushing" of current carriers from the center of the wire strand toward its surface layer. This phenomenon causes an uneven distribution of current density* across the cross-section. High-frequency litz wire is a conductor made of many very thin strands insulated with varnish. A strand with a small cross-section achieves a more favorable ratio of the active cross-section conducting current to the cross-section through which current does not flow.

The way to reduce the skin effect is to decrease the active cross-section of a single conductor by using many thin wires known as litz wire.

*The current density in a wire strand increases from its center toward the outer edge. In extreme cases, current may not flow through the central part of the strand at all. As frequency increases, the current-carrying capacity of the conductors decreases.

How Do High-Frequency Litz Wires Work?

Litz wires, whose name comes from the German term "die Litze," meaning stranded wire, provide efficient current conduction in high-frequency conductors. Their application effectively prevents the occurrence of the skin effect as well as eddy currents.

Because litz wires consist of many thin and insulated wires that act as surfaces through which the signal can flow, they allow for the full utilization of conducting potential. They evenly distribute electromagnetic fields and eliminate eddy currents induced by changing magnetic fields. This is possible because their twisted wires are independent conducting channels that are not excessively locally overloaded.

Where Are High-Frequency Litz Wires Used?

High-frequency litz wires are widely used in electrical systems. They are primarily utilized for manufacturing inductive coils and transformers, especially for high-frequency applications. In addition, they are commonly found in:

- wireless power supply systems,

- hybrid vehicles,

- radio transmitters,

- high-frequency power converters.

What Are the Main Advantages of Using Litz Wire?

Litz wires used in electrical systems operating at high frequencies ensure effective reduction of losses caused by the skin effect. Thanks to them, current can flow evenly through their many thin strands, thereby increasing the effective conducting cross-section. This makes litz wires capable of significantly improving the energy efficiency of an electrical system.

Even current distribution across the entire litz cross-section also means the wires do not overheat during operation. As a result, electrical systems using them are more reliable.

Litz wires also generate lower electromagnetic interference (EMI). This means they provide high signal stability during transmission. The production of these multi-stranded conductors from many thin wire strands also results in high flexibility. Therefore, they can be easily used in various systems. Additionally, other advantages of using them in electrical systems include the possibility of reducing the size and weight of components.

Litz wires can also be adapted to various requirements of electrical systems in terms of:

- the number of strands, which can range from a few to tens of thousands,

- strand size,

- insulation material,

- total wire diameter.

All these features make high-frequency litz wires an excellent choice for systems that need to operate at high frequencies while maintaining high efficiency.

What Types of High-Frequency Litz Wires Are There?

High-frequency litz wires are divided into two types based on their shape. The first type includes conductors with a round cross-section. This shape ensures very good and even current distribution and minimizes the skin effect. They are also less prone to losses caused by electrical resistance. Round litz wires are commonly used in transformers and inductors.

The second type includes profiled litz wires with a rectangular or square cross-section. They allow for better space utilization in windings, which results in minimized energy transfer losses.

What Materials Are High-Frequency Litz Wires Made From?

In terms of materials, litz wires are available in copper or aluminum versions. Copper wires offer excellent electrical conductivity along with a low thermal expansion coefficient. As a result, they ensure high current transmission efficiency. Additionally, copper litz wires are highly corrosion-resistant, even in environments with increased humidity or other corrosive factors. However, it is important to note that they may be prone to metal oxidation.

Aluminum litz wires, while offering lower electrical conductivity, are lighter. Therefore, their use is justified in systems where weight is a critical factor. Since aluminum naturally forms an oxide layer on its surface, aluminum litz wires are also corrosion-resistant, just like their copper counterparts.

DACPOL offers both round and profiled litz wires made of copper or aluminum. Additionally, we provide the possibility of delivering custom-made high-frequency litz wire tailored specifically to the electrical system in terms of strand number and size as well as the type of insulation used.