Category

Photos are for informational purposes only. View product specification

please use latin characters

The introduction of the GKS product marks a significant new product class for Honeywell. Honeywell’s switching expertise has been applied to a cost-effective, trapped key safety interlock switch. This product allows OEMs to hold a door or gate closed while a hazard still exists. This is particularly important where there is moment

um in the machine. In other words, when the machine is signaled to stop, the momentum in the machine can mean that parts of the machine are still moving and pose an injury risk if the access gate or door is not held closed. Global approvals and standards are important to Honeywell’s customers; therefor e, the GKS product conform to

the requirements of IEC60947-5-1 and carries cULus, CE and CCC approvals

FEATURES:

• Global approvals (CE, cULus, CE, and CCC)

• Glass-filled polyester body

• Power-to-lock and power-to-unlock schemes for key trap

• Flexible switching arrangement

• 24 Vdc, 110 Vac, and 230 Vac coil voltages

• Over-ride mechanism in cover

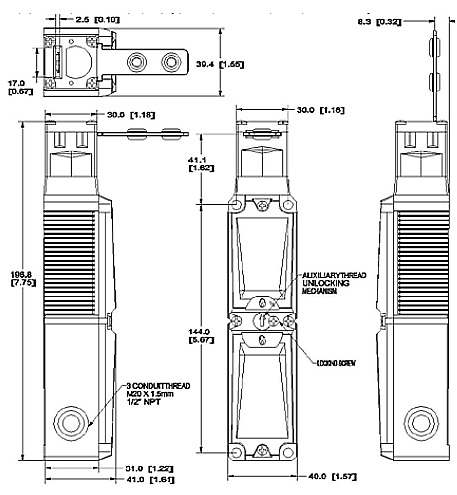

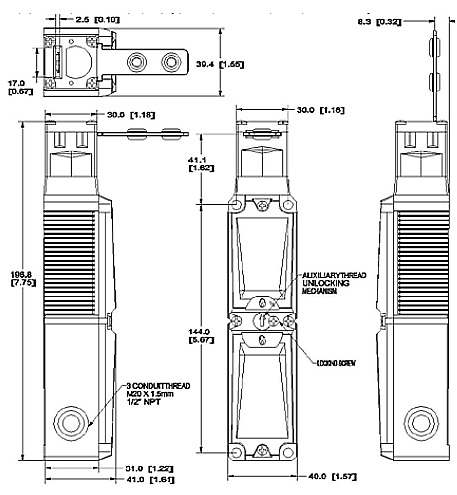

• Head may be rotated into 4 different positions

• Three conduit openings (knock-out style)

• Switch position provides status .

Benefits

• Product may be applied to most applications worldwide

• Tough, cost-effective, double-insulated enclosure

• Choice of key trapping methodology

• Four contacts that can be arranged in any configuration

• Multiple voltages provide for every geography

• Has a method to open door (in case of power loss, etc.)

• One part number may be used for multiple applications

• Flexible wiring options

• Can diagnose status of gate/door (gate/door closed and locked, gate/door closed and unlocked, gate/door open)

Caution

There will be minimum volume requirements for unreleased

options.

POTENTIAL APPLICATIONS

• Woodworking machinery

• Printing/paper finishing equipment

• Plastic molding equipment

• Packaging machinery

• Bailing

• Pumping equipment

• Semiconductor manufacturing equipment

• Packaging wrapping

• Specialty equipment

• Machine tool

• Robot cell

| Designation and Utilization Category |

Rated Operational Current Ie (A) at Rated Operational Voltage Ue (V) | |||

|---|---|---|---|---|

| 120 V~ | 125 V= | 240 V~ / 250 V= | ||

| AC15 | B300 | 3 A | - | 1,5 A |

| DC13 | Q300 | - | 0,55 A | 0,27 A |

|

Rated thermal current (Ith)

|

5A

|

|

|---|---|---|

|

Sealing

|

IP67; NEMA 1, 4, 12, 13

|

|

|

Rated impulse withstand (Uimp)

|

2500 V

|

|

|

Pollution degree

|

3 (macro-environment, installation environment)

|

|

|

Rated insulation voltage (Ui)

|

600 V

|

|

|

Operating temperature range

|

-25 °C do 50 °C [-13 °F do 122 °F]

|

|

|

Storage temperature range

|

-40 °C do 85 °C [-40 °F do 185 °F]

|

|

|

Short-circuit protective device (type/maximum

rating)

|

Class J fuse (5 A/600 Vac)

|

|

|

Expected mechanical life

|

1 000 000 cycles

|

|

|

Conditional short-circuit current

|

1000 A

|

|

|

Solenoid operating voltage and power

|

24V~: +10%, -15%, 4 W

110 V~: +10%, -15%, 8 W |

230 V~: +10%, -15%, 9 W 24V~: +10%, -20%, 7 W |

Complies with:

IEC/EN60947-5-1

| GKS | X | XX | X | X | X | X |

|---|---|---|---|---|---|---|

| Series | Conduit | Contacts | Head orientation | Locking principal | solenoid voltage | Additional functions |

|

Door interlock safety limit switch, solenoid

|

A - NPT 1/2" C - M20x1,5

|

21 - 2NC/1NO/1NO

22 - 2NC/1NO/1NC 46 - 3NC/1NO 47 -4NC |

L - front

N - back P - left M - right |

A - Power to unlock

S - Power to lock |

2 - 24V~/=

5 -110V~ 6 - 230V~ |

L - LED

|

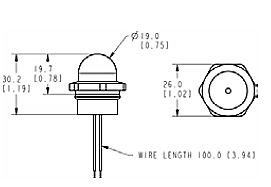

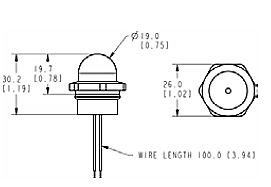

LED OPTION

|

LED color

|

Red

|

|---|---|

|

Connection

|

2 connection cables

|

|

Screw-in thread

|

M20 x 1,5 / ½”NPT

|

|

Operating voltage/current

consumption

|

24V= /45mA

115V~/15mA 230V~/15mA |

|

Degree of protection

|

IP67

|

|

|

| Type | Description |

|---|---|

| GKSA46LA2 |

0.5 in conduit, 3NC/1NO, head to front, power to unlock, 24 Vdc solenoid

|

| GKSA46LA5 |

0.5 in conduit, 3NC/1NO, head to front, power to unlock, 110 Vac solenoid

|

| GKSC46I_A2 |

20 mm conduit, 3NC/1NO, head to front, power to unlock, 24 Vdc solenoid

|

| GKSC46LA6 |

20 mm conduit, 3NC/1NO, head to front, power to unlock, 230 Vac solenoid

|

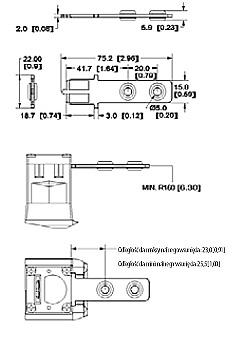

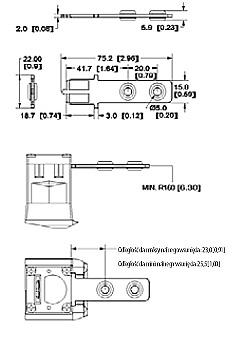

| Type | Description | Min. Actuating Radius |

|---|---|---|

| GKZS6 | Straight key | min. R 160 [6,30] |

| GKZS7 | 90o key | min. R 160 [6,30] |

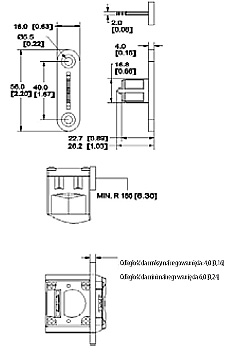

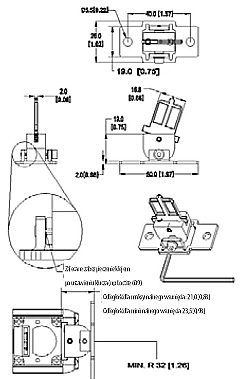

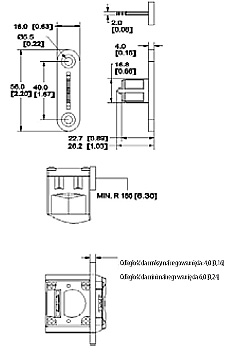

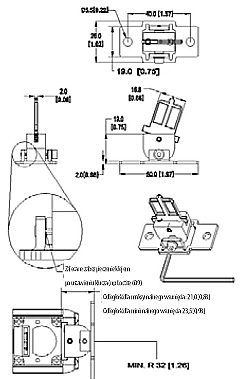

| GKZS8 | Left-right adjustable key | min. R 32 [1,26] |

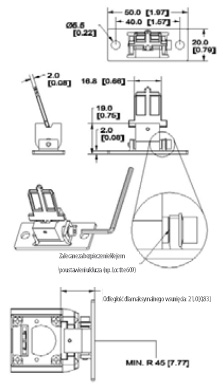

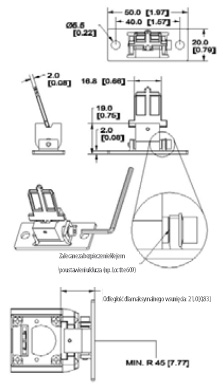

| GKZS4 | Up-down adjustable key | min. R 45 [1,77] |

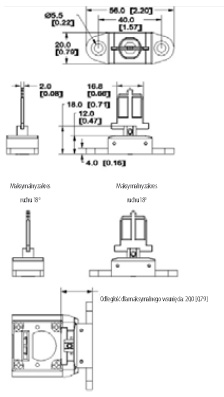

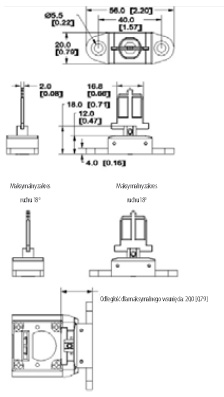

| GKZS9 | Multi directional key | moveable max 18 degrees |

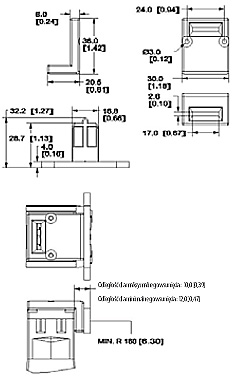

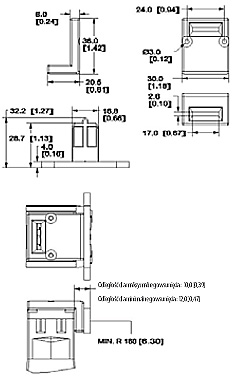

| GKZSF | Funnel key | min. R 160 [6,30] |

|

NOTE: This ‘truth table’ shows the switch status in various conditions. In each column, there is a change in switch contact

position from the previous column. It is possible to determine the status of the switch by examining the combination against the table. This can be essential for operational reasons. For instance, the machine should not be started until the key is not only in the head, but is also trapped.

The first column depicts the key inserted and the key trapped in that position – this would be the typical run position for the machine – all doors closed. The second column illustrates the key inserted, but not trapped – this would be the safe-to-open the door position (as determined by the application’s safety scheme). The third column shows the key extracted or door-open position

|

|

GKZS6

|

GKZS7

|

GKZS8

|

|

|

|

|

GKZS4

|

GKZS9

|

GKZSF

|

|

|

|

Are you interested in this product? Do you need additional information or individual pricing?

The introduction of the GKS product marks a significant new product class for Honeywell. Honeywell’s switching expertise has been applied to a cost-effective, trapped key safety interlock switch. This product allows OEMs to hold a door or gate closed while a hazard still exists. This is particularly important where there is moment

um in the machine. In other words, when the machine is signaled to stop, the momentum in the machine can mean that parts of the machine are still moving and pose an injury risk if the access gate or door is not held closed. Global approvals and standards are important to Honeywell’s customers; therefor e, the GKS product conform to

the requirements of IEC60947-5-1 and carries cULus, CE and CCC approvals

FEATURES:

• Global approvals (CE, cULus, CE, and CCC)

• Glass-filled polyester body

• Power-to-lock and power-to-unlock schemes for key trap

• Flexible switching arrangement

• 24 Vdc, 110 Vac, and 230 Vac coil voltages

• Over-ride mechanism in cover

• Head may be rotated into 4 different positions

• Three conduit openings (knock-out style)

• Switch position provides status .

Benefits

• Product may be applied to most applications worldwide

• Tough, cost-effective, double-insulated enclosure

• Choice of key trapping methodology

• Four contacts that can be arranged in any configuration

• Multiple voltages provide for every geography

• Has a method to open door (in case of power loss, etc.)

• One part number may be used for multiple applications

• Flexible wiring options

• Can diagnose status of gate/door (gate/door closed and locked, gate/door closed and unlocked, gate/door open)

Caution

There will be minimum volume requirements for unreleased

options.

POTENTIAL APPLICATIONS

• Woodworking machinery

• Printing/paper finishing equipment

• Plastic molding equipment

• Packaging machinery

• Bailing

• Pumping equipment

• Semiconductor manufacturing equipment

• Packaging wrapping

• Specialty equipment

• Machine tool

• Robot cell

| Designation and Utilization Category |

Rated Operational Current Ie (A) at Rated Operational Voltage Ue (V) | |||

|---|---|---|---|---|

| 120 V~ | 125 V= | 240 V~ / 250 V= | ||

| AC15 | B300 | 3 A | - | 1,5 A |

| DC13 | Q300 | - | 0,55 A | 0,27 A |

|

Rated thermal current (Ith)

|

5A

|

|

|---|---|---|

|

Sealing

|

IP67; NEMA 1, 4, 12, 13

|

|

|

Rated impulse withstand (Uimp)

|

2500 V

|

|

|

Pollution degree

|

3 (macro-environment, installation environment)

|

|

|

Rated insulation voltage (Ui)

|

600 V

|

|

|

Operating temperature range

|

-25 °C do 50 °C [-13 °F do 122 °F]

|

|

|

Storage temperature range

|

-40 °C do 85 °C [-40 °F do 185 °F]

|

|

|

Short-circuit protective device (type/maximum

rating)

|

Class J fuse (5 A/600 Vac)

|

|

|

Expected mechanical life

|

1 000 000 cycles

|

|

|

Conditional short-circuit current

|

1000 A

|

|

|

Solenoid operating voltage and power

|

24V~: +10%, -15%, 4 W

110 V~: +10%, -15%, 8 W |

230 V~: +10%, -15%, 9 W 24V~: +10%, -20%, 7 W |

Complies with:

IEC/EN60947-5-1

| GKS | X | XX | X | X | X | X |

|---|---|---|---|---|---|---|

| Series | Conduit | Contacts | Head orientation | Locking principal | solenoid voltage | Additional functions |

|

Door interlock safety limit switch, solenoid

|

A - NPT 1/2" C - M20x1,5

|

21 - 2NC/1NO/1NO

22 - 2NC/1NO/1NC 46 - 3NC/1NO 47 -4NC |

L - front

N - back P - left M - right |

A - Power to unlock

S - Power to lock |

2 - 24V~/=

5 -110V~ 6 - 230V~ |

L - LED

|

LED OPTION

|

LED color

|

Red

|

|---|---|

|

Connection

|

2 connection cables

|

|

Screw-in thread

|

M20 x 1,5 / ½”NPT

|

|

Operating voltage/current

consumption

|

24V= /45mA

115V~/15mA 230V~/15mA |

|

Degree of protection

|

IP67

|

|

|

| Type | Description |

|---|---|

| GKSA46LA2 |

0.5 in conduit, 3NC/1NO, head to front, power to unlock, 24 Vdc solenoid

|

| GKSA46LA5 |

0.5 in conduit, 3NC/1NO, head to front, power to unlock, 110 Vac solenoid

|

| GKSC46I_A2 |

20 mm conduit, 3NC/1NO, head to front, power to unlock, 24 Vdc solenoid

|

| GKSC46LA6 |

20 mm conduit, 3NC/1NO, head to front, power to unlock, 230 Vac solenoid

|

| Type | Description | Min. Actuating Radius |

|---|---|---|

| GKZS6 | Straight key | min. R 160 [6,30] |

| GKZS7 | 90o key | min. R 160 [6,30] |

| GKZS8 | Left-right adjustable key | min. R 32 [1,26] |

| GKZS4 | Up-down adjustable key | min. R 45 [1,77] |

| GKZS9 | Multi directional key | moveable max 18 degrees |

| GKZSF | Funnel key | min. R 160 [6,30] |

|

NOTE: This ‘truth table’ shows the switch status in various conditions. In each column, there is a change in switch contact

position from the previous column. It is possible to determine the status of the switch by examining the combination against the table. This can be essential for operational reasons. For instance, the machine should not be started until the key is not only in the head, but is also trapped.

The first column depicts the key inserted and the key trapped in that position – this would be the typical run position for the machine – all doors closed. The second column illustrates the key inserted, but not trapped – this would be the safe-to-open the door position (as determined by the application’s safety scheme). The third column shows the key extracted or door-open position

|

|

GKZS6

|

GKZS7

|

GKZS8

|

|

|

|

|

GKZS4

|

GKZS9

|

GKZSF

|

|

|

|

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent