Category

Photos are for informational purposes only. View product specification

please use latin characters

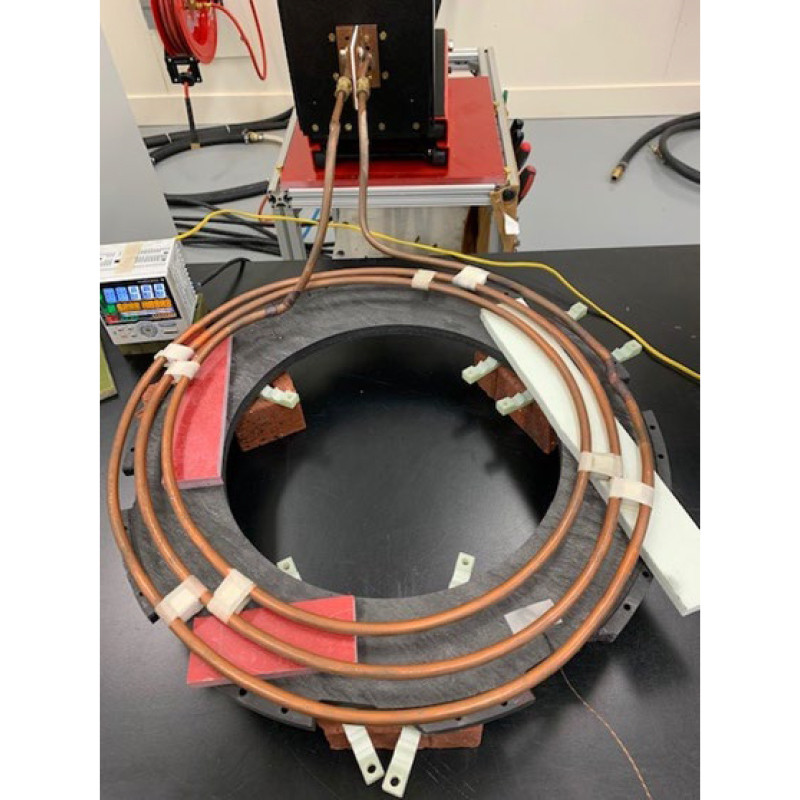

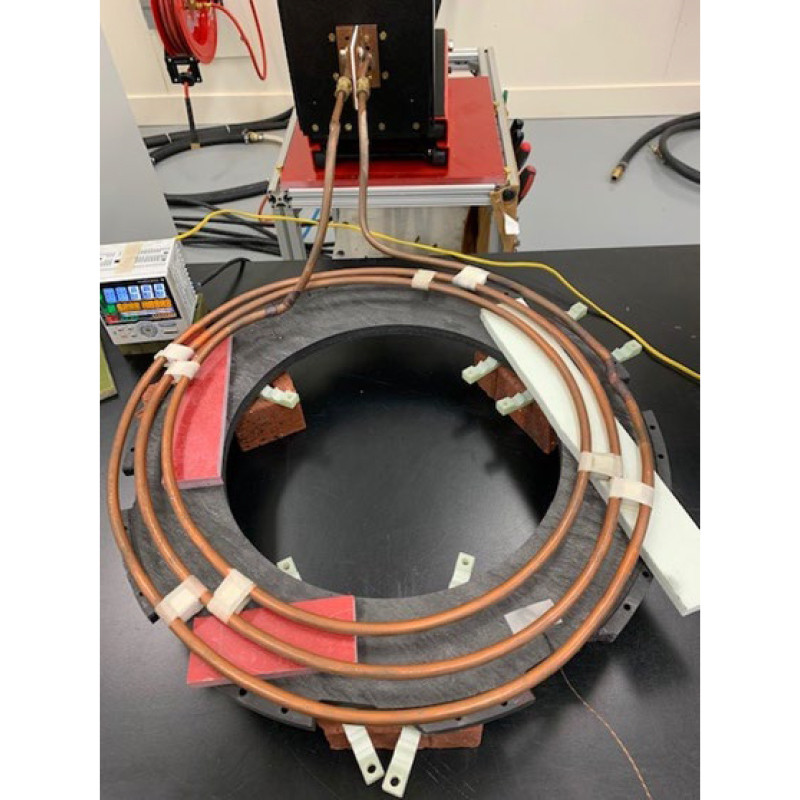

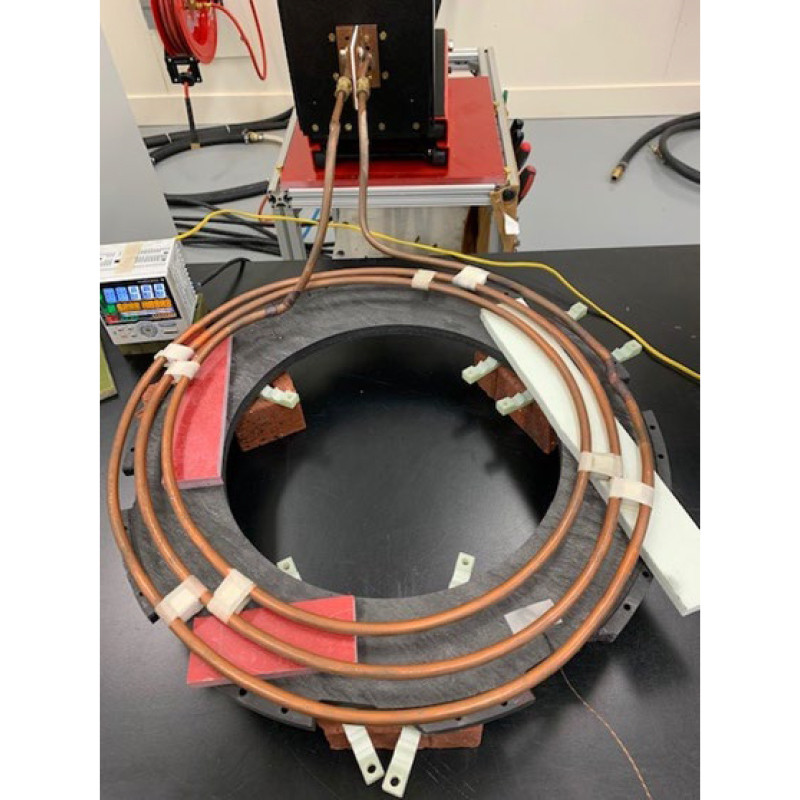

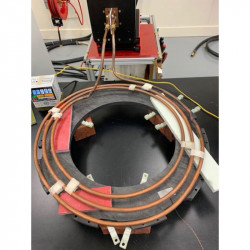

Objective: To heat an assortment of graphite discs of variable sizes; the client was from the aerospace industry.

Material: Graphite discs

Temperature: 200 ºF (93 ºC)

A custom-designed single position multiple-turn pancake coil was built to generate the required heating for this application. Initial tests were conducted to optimize the power delivered to the part. The coil was held 0.5” (12.7 mm) above the top surface of the part. Thermocouples were attached to the top and bottom surfaces of the part. It took 45 seconds to heat the sample to the target temperature of 200 °F (93 °C) on the surface closest to the coil. The surface farther from the coil reached 180°F (82 °C) in this time. It is possible to use closed-loop temperature control with the EKOHEAT to bring the top surface to temperature and hold it while the farther surface is brought to temperature.

Are you interested in this product? Do you need additional information or individual pricing?

Objective: To heat an assortment of graphite discs of variable sizes; the client was from the aerospace industry.

Material: Graphite discs

Temperature: 200 ºF (93 ºC)

A custom-designed single position multiple-turn pancake coil was built to generate the required heating for this application. Initial tests were conducted to optimize the power delivered to the part. The coil was held 0.5” (12.7 mm) above the top surface of the part. Thermocouples were attached to the top and bottom surfaces of the part. It took 45 seconds to heat the sample to the target temperature of 200 °F (93 °C) on the surface closest to the coil. The surface farther from the coil reached 180°F (82 °C) in this time. It is possible to use closed-loop temperature control with the EKOHEAT to bring the top surface to temperature and hold it while the farther surface is brought to temperature.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent