Category

Photos are for informational purposes only. View product specification

please use latin characters

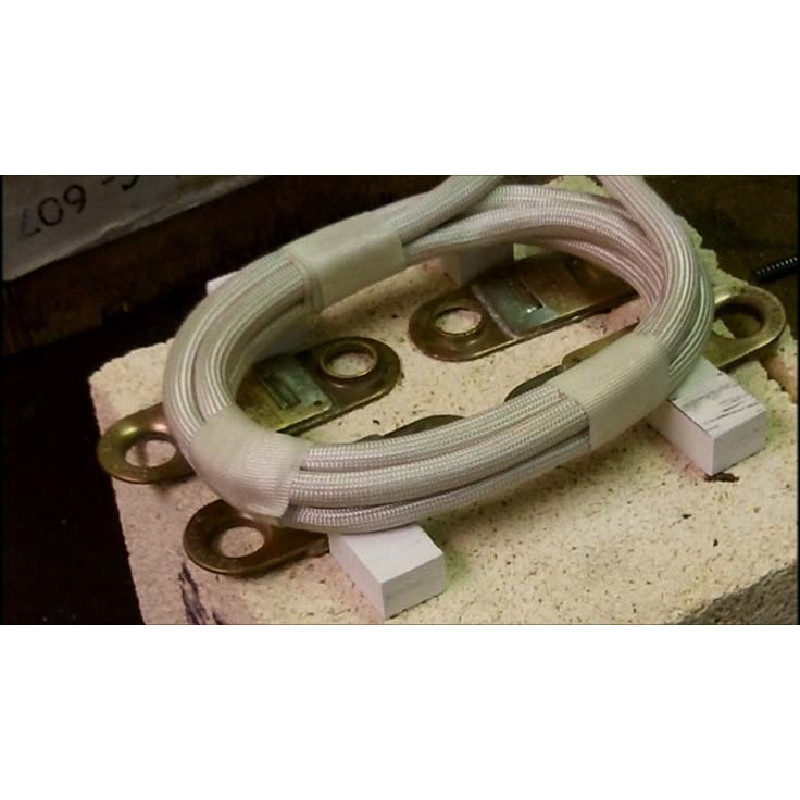

Objective: To heat copper strips of various sizes to 400 ºF (204 ºC) for a soldering application; the client was heating two fusible strips concurrently but would like to heat four concurrently with induction.

Frequency: 175 kHz

Material: Copper strips, solder

Temperature: 400 °F (204 °C)

Initial tests were conducted to optimize the power delivered to the copper strip. Four parts were placed under the coil approximately 0.25 inches (6.4 mm) away from it. The power was turned on and after seven seconds the larger parts began to separate indicating that the solder had reached the flow point. A heating time of 10 seconds will ensure good flow. Placing the center of the coil turn over the center of the joint area offers the best performance for this application.

Are you interested in this product? Do you need additional information or individual pricing?

Objective: To heat copper strips of various sizes to 400 ºF (204 ºC) for a soldering application; the client was heating two fusible strips concurrently but would like to heat four concurrently with induction.

Frequency: 175 kHz

Material: Copper strips, solder

Temperature: 400 °F (204 °C)

Initial tests were conducted to optimize the power delivered to the copper strip. Four parts were placed under the coil approximately 0.25 inches (6.4 mm) away from it. The power was turned on and after seven seconds the larger parts began to separate indicating that the solder had reached the flow point. A heating time of 10 seconds will ensure good flow. Placing the center of the coil turn over the center of the joint area offers the best performance for this application.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent