Category

Photos are for informational purposes only. View product specification

please use latin characters

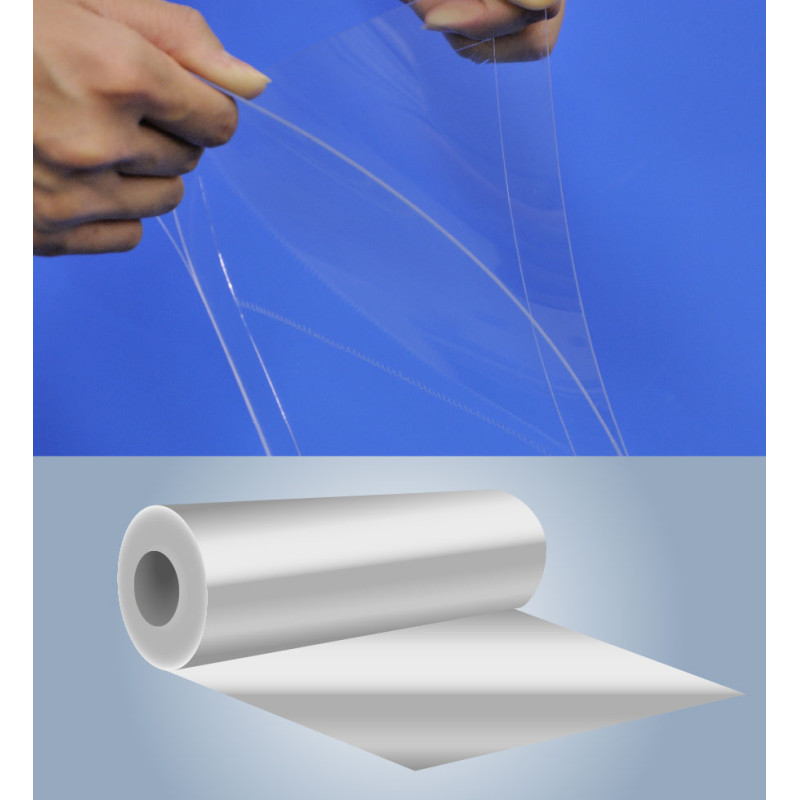

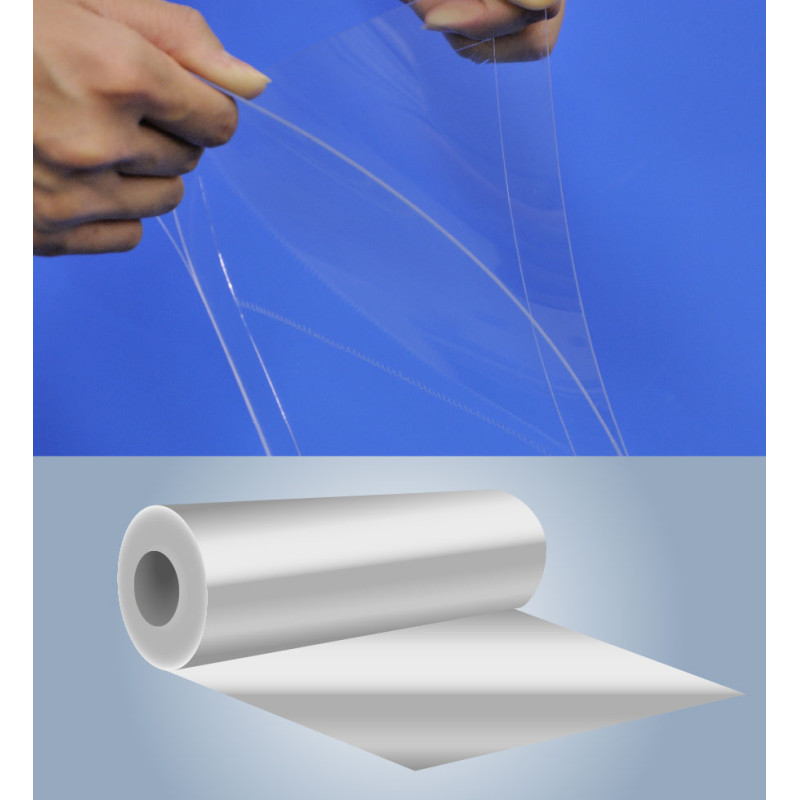

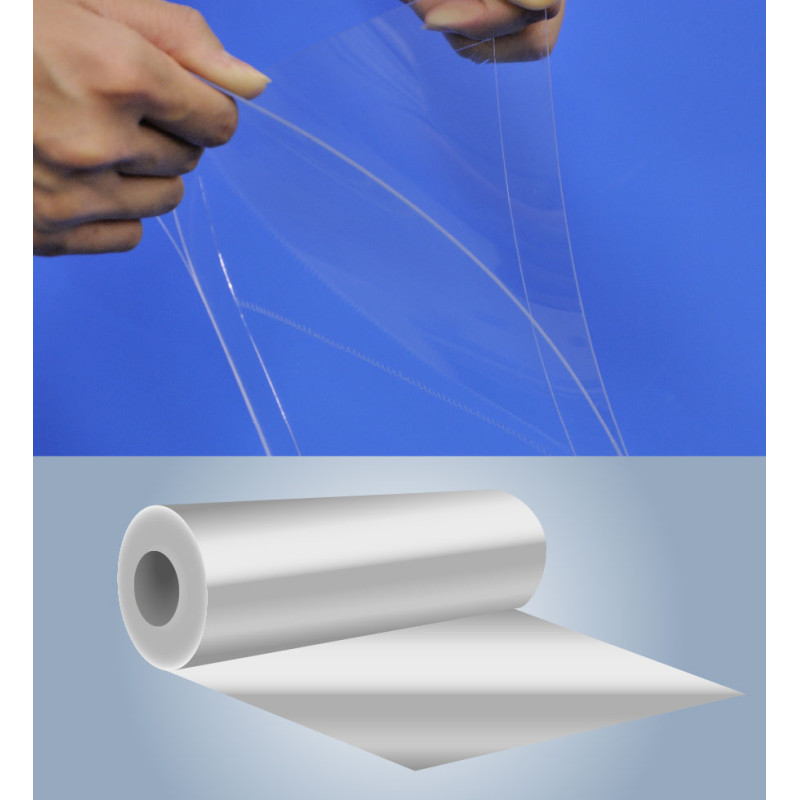

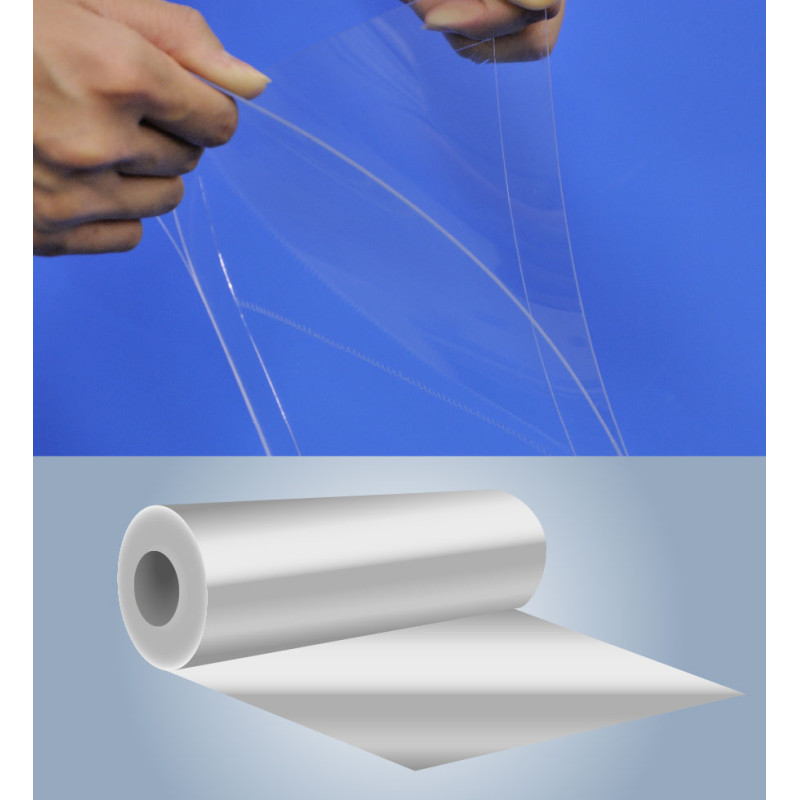

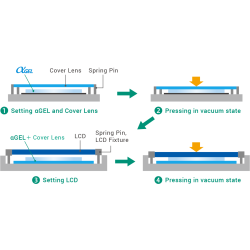

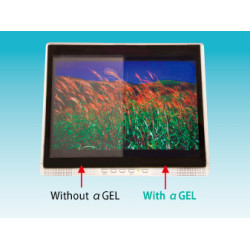

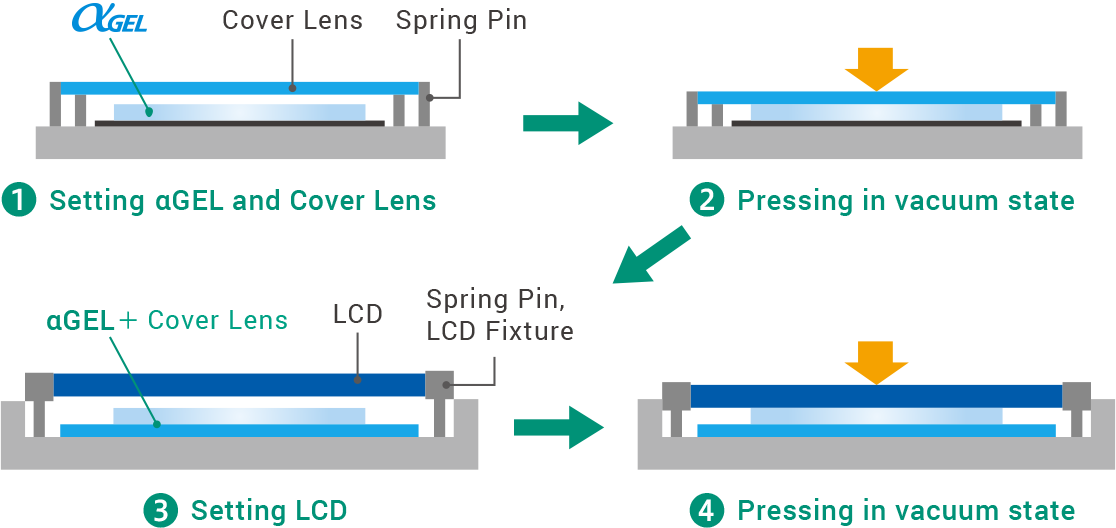

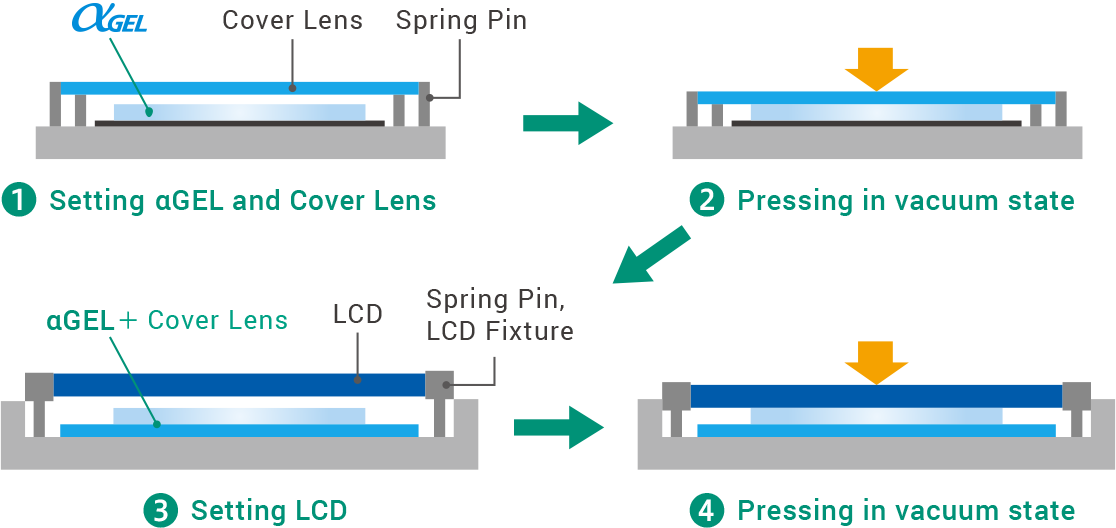

Silicone Optical Clear Adhesive (OCA) fills the air spaces between components in LCD displays, improving brightness and contrast. It is highly resistant to yellowing and offers excellent long-term performance. We sell our Silicone OCA in sheets for easy handling and reusability.

Inserting Silicon OCA between the LCD unit and the cover glass offers many benefits, such as increased shock resistance, reduced stress, increased contrast, reduced parallax, and improved brightness.

| Characteristics | Parameters | Method | Condition① | Condition② | Unit | K120E (-D) | K95E (-D) | Notes |

|---|---|---|---|---|---|---|---|---|

| Mechanical Properties |

Hardness | Penetrometer | Cup: 40ml | − | 1/10mm | 120 | 95 | JIS K 2207 |

| Young's Modulus | Tensile Tester | φ30mm×t12.7mm | 1mm/min (Compression) | kPa | 22 | 48 | Elastic Modulus Compressive Strength | |

| Tensile Strength at Break |

Tensile Tester | K120E: t1.0mm K95E: t1.8mm |

200mm/min | % | 1265 | 1050 | JIS K 6815-1 | |

| Viscoelasticity tanδ | Viscoelasticity Measuring Device | φ25mm×t1.8mm @10Hz |

20°C | − | 0.54 | 0.45 | − | |

| 100°C | − | 0.56 | 0.45 | |||||

| Optical Properties | Total Light Transmittance | Fog Meter | K120E: t0.5mm K95E: t1.8mm |

Room Temperature | % | 92.7 | 92.5 | JIS K 7136 |

| 95°C×1000h | % | 92.5 | 91.5 | |||||

| 85°C_85%×1000h | % | 92.4 | 92.2 | |||||

| Spectral light transmission | Spectrophotometer | K120E: t0.5mm K95E: t1.8mm |

380nm | % | 91 | 91 | JIS K 7105 | |

| 780nm | % | 91 | 91 | |||||

| B value* | Spectrophotometer | K120E: t0.5mm K95E: t1.8mm |

Room temperature | − | 0.14 | 0.20 | ||

| 95°C×1000h | − | 0.39 | 0.86 | |||||

| − | 0.27 | 0.36 | ||||||

| Fog | Fog Meter | K120E: t0.5mm K95E: t1.8mm |

Room Temperature | % | 0.24 | 0.42 | JIS K 7136 | |

| 95°C×1000h | % | 0.33 | 0.61 | |||||

| 85°C_85%×1000h | % | 0.31 | 0.60 | |||||

| Abbe refractometer | 25×25×t0.5mm | 23°C/589nm | − | 1.41 | 1.41 | JIS K 7142 | ||

| Other | Density | Electronic gravimeter: | − | − | 0.98 | − |

※Silicone oil may leak depending on conditions.

※This product contains low molecular weight siloxane, which is mainly composed of silicone.

※The above data is measured data and not guaranteed specifications.

| Measurement wavelength |

Initial | High temperature exposure |

Hot and humid climate |

Heat cycle | Light resistance |

Low temperature storage |

|---|---|---|---|---|---|---|

| 85℃ | 60℃× 90%RH |

-40℃ ⇔85℃ |

150W /m2 |

-40℃ | ||

| 400nm | 91 | 91 | 91 | 91 | 91 | 91 |

| 800nm | 91 | 91 | 91 | 91 | 91 | 91 |

| Time after lamination(h) |

PMMA | Tempered glass |

|---|---|---|

| 0 | 6.2 | 8.8 |

| 120 | 12.8 | 14.6 |

| 500 | 13.4 | 14.4 |

| 1000 | 13.4 | 14.4 |

| Item | Thickness(mm) | Width(mm) | Length(M) | Core(inch) | Liner | Adhesion Strength vs liner(N/20mm) | ||

|---|---|---|---|---|---|---|---|---|

| Liner | Effective | Peel1 (Weak Adhesion) |

Peel2 (Strong Adhesion) |

|||||

| K120E (-D) |

t0.175/t0.2/t0.25/ t0.3/t0.5 |

500 | 460 | 50 | 3/6 | Liner on one-side |

0.05 | 0.7 |

| K120E (-D) |

t0.8/t1.0 | 500 | 440 | 25 | 3/6 | Liner on one-side |

0.05 | 0.7 |

| K95E (-D) |

t1.2/t1.5/t1.8 | 500 | 400 | 25 | 3/6 | Liner on one-side |

0.03 | 0.5 |

![]()

Are you interested in this product? Do you need additional information or individual pricing?

Silicone Optical Clear Adhesive (OCA) fills the air spaces between components in LCD displays, improving brightness and contrast. It is highly resistant to yellowing and offers excellent long-term performance. We sell our Silicone OCA in sheets for easy handling and reusability.

Inserting Silicon OCA between the LCD unit and the cover glass offers many benefits, such as increased shock resistance, reduced stress, increased contrast, reduced parallax, and improved brightness.

| Characteristics | Parameters | Method | Condition① | Condition② | Unit | K120E (-D) | K95E (-D) | Notes |

|---|---|---|---|---|---|---|---|---|

| Mechanical Properties |

Hardness | Penetrometer | Cup: 40ml | − | 1/10mm | 120 | 95 | JIS K 2207 |

| Young's Modulus | Tensile Tester | φ30mm×t12.7mm | 1mm/min (Compression) | kPa | 22 | 48 | Elastic Modulus Compressive Strength | |

| Tensile Strength at Break |

Tensile Tester | K120E: t1.0mm K95E: t1.8mm |

200mm/min | % | 1265 | 1050 | JIS K 6815-1 | |

| Viscoelasticity tanδ | Viscoelasticity Measuring Device | φ25mm×t1.8mm @10Hz |

20°C | − | 0.54 | 0.45 | − | |

| 100°C | − | 0.56 | 0.45 | |||||

| Optical Properties | Total Light Transmittance | Fog Meter | K120E: t0.5mm K95E: t1.8mm |

Room Temperature | % | 92.7 | 92.5 | JIS K 7136 |

| 95°C×1000h | % | 92.5 | 91.5 | |||||

| 85°C_85%×1000h | % | 92.4 | 92.2 | |||||

| Spectral light transmission | Spectrophotometer | K120E: t0.5mm K95E: t1.8mm |

380nm | % | 91 | 91 | JIS K 7105 | |

| 780nm | % | 91 | 91 | |||||

| B value* | Spectrophotometer | K120E: t0.5mm K95E: t1.8mm |

Room temperature | − | 0.14 | 0.20 | ||

| 95°C×1000h | − | 0.39 | 0.86 | |||||

| − | 0.27 | 0.36 | ||||||

| Fog | Fog Meter | K120E: t0.5mm K95E: t1.8mm |

Room Temperature | % | 0.24 | 0.42 | JIS K 7136 | |

| 95°C×1000h | % | 0.33 | 0.61 | |||||

| 85°C_85%×1000h | % | 0.31 | 0.60 | |||||

| Abbe refractometer | 25×25×t0.5mm | 23°C/589nm | − | 1.41 | 1.41 | JIS K 7142 | ||

| Other | Density | Electronic gravimeter: | − | − | 0.98 | − |

※Silicone oil may leak depending on conditions.

※This product contains low molecular weight siloxane, which is mainly composed of silicone.

※The above data is measured data and not guaranteed specifications.

| Measurement wavelength |

Initial | High temperature exposure |

Hot and humid climate |

Heat cycle | Light resistance |

Low temperature storage |

|---|---|---|---|---|---|---|

| 85℃ | 60℃× 90%RH |

-40℃ ⇔85℃ |

150W /m2 |

-40℃ | ||

| 400nm | 91 | 91 | 91 | 91 | 91 | 91 |

| 800nm | 91 | 91 | 91 | 91 | 91 | 91 |

| Time after lamination(h) |

PMMA | Tempered glass |

|---|---|---|

| 0 | 6.2 | 8.8 |

| 120 | 12.8 | 14.6 |

| 500 | 13.4 | 14.4 |

| 1000 | 13.4 | 14.4 |

| Item | Thickness(mm) | Width(mm) | Length(M) | Core(inch) | Liner | Adhesion Strength vs liner(N/20mm) | ||

|---|---|---|---|---|---|---|---|---|

| Liner | Effective | Peel1 (Weak Adhesion) |

Peel2 (Strong Adhesion) |

|||||

| K120E (-D) |

t0.175/t0.2/t0.25/ t0.3/t0.5 |

500 | 460 | 50 | 3/6 | Liner on one-side |

0.05 | 0.7 |

| K120E (-D) |

t0.8/t1.0 | 500 | 440 | 25 | 3/6 | Liner on one-side |

0.05 | 0.7 |

| K95E (-D) |

t1.2/t1.5/t1.8 | 500 | 400 | 25 | 3/6 | Liner on one-side |

0.03 | 0.5 |

![]()

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent