Category

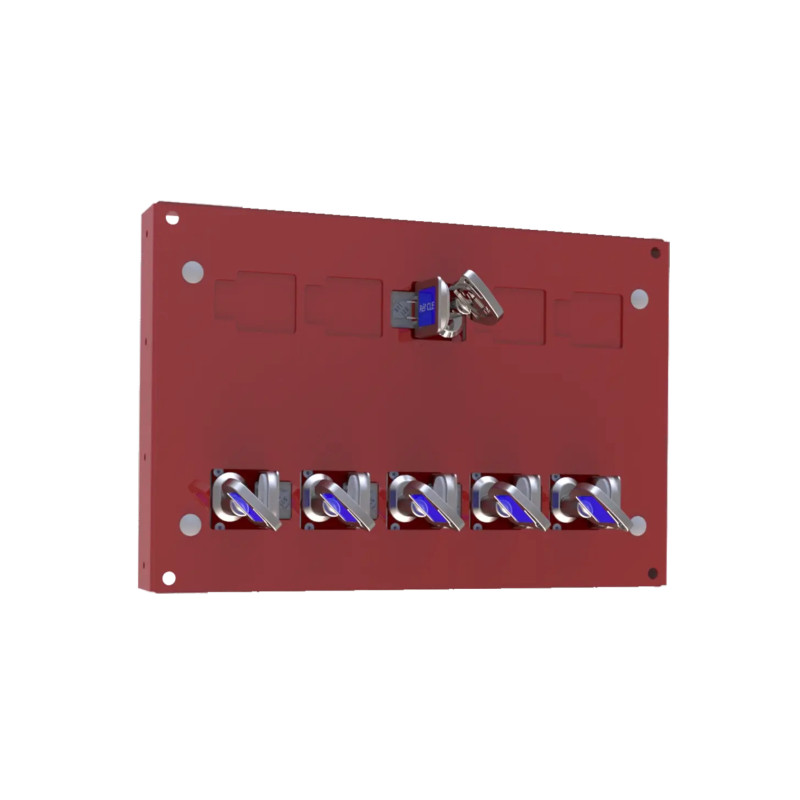

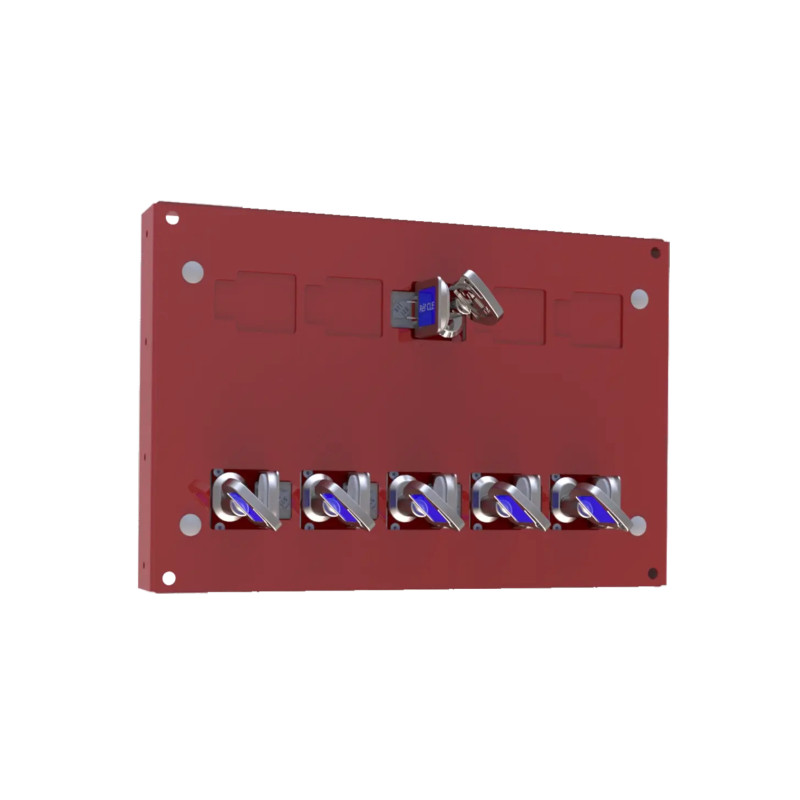

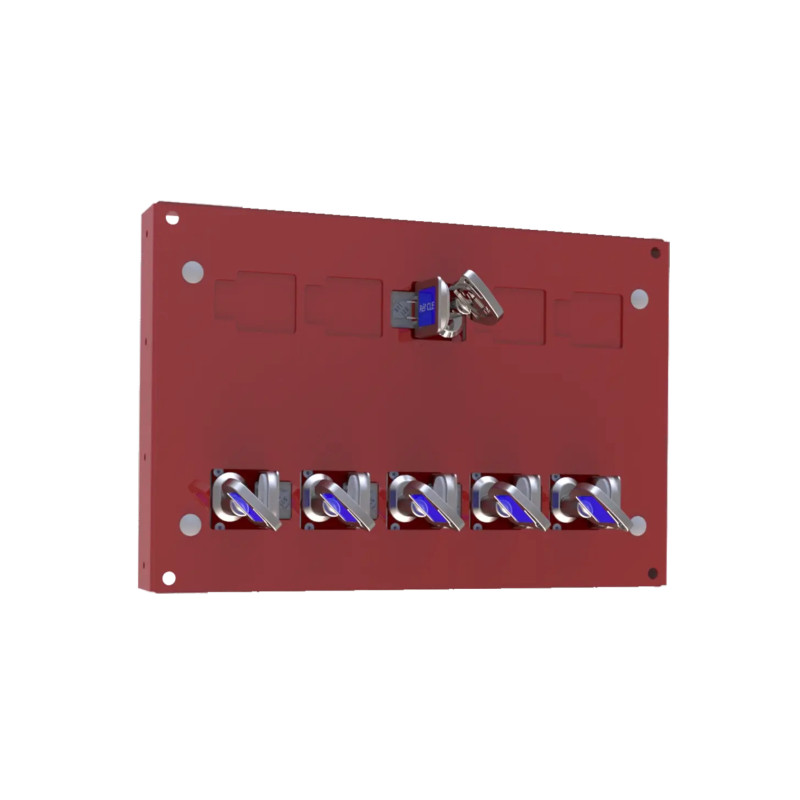

Photos are for informational purposes only. View product specification

please use latin characters

Are you interested in this product? Do you need additional information or individual pricing?

Precast Concrete Industry – Application Series: 2 of 5

Precast Concrete Industry – Application Series: 2 of 5

Precast Concrete Industry – Application Series: 3 of 5

Precast Concrete Industry – Application Series: 3 of 5

Przemysł prefabrykatów betonowych — seria zastosowań: 4 z 5

Przemysł prefabrykatów betonowych — seria zastosowań: 4 z 5

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent