Category

Photos are for informational purposes only. View product specification

please use latin characters

For an electronic device to function properly, it is necessary to analyze and predict the environment in which it will operate. Factors such as temperature, humidity, salinity, and chemical agents are just some of the parameters that should be considered when selecting appropriate components.

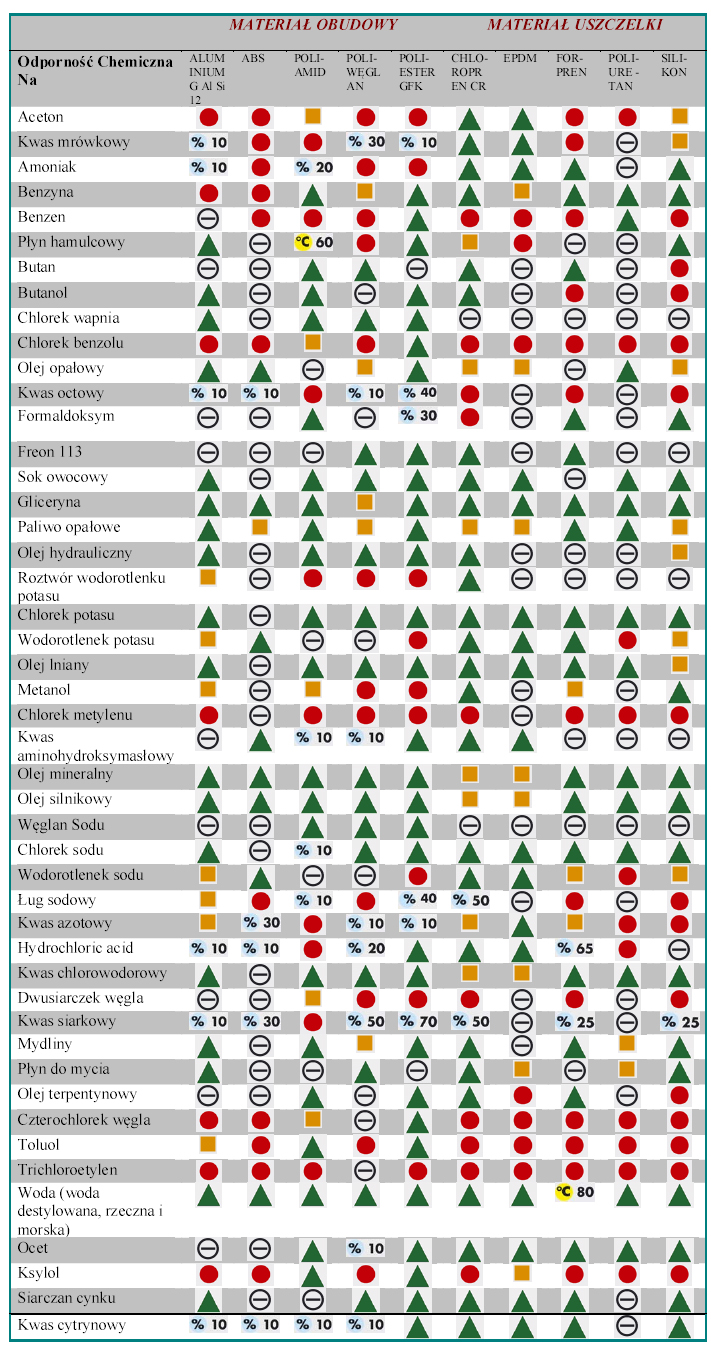

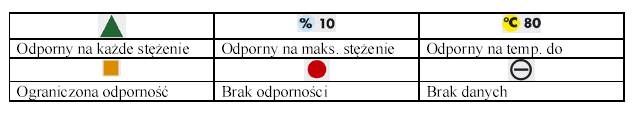

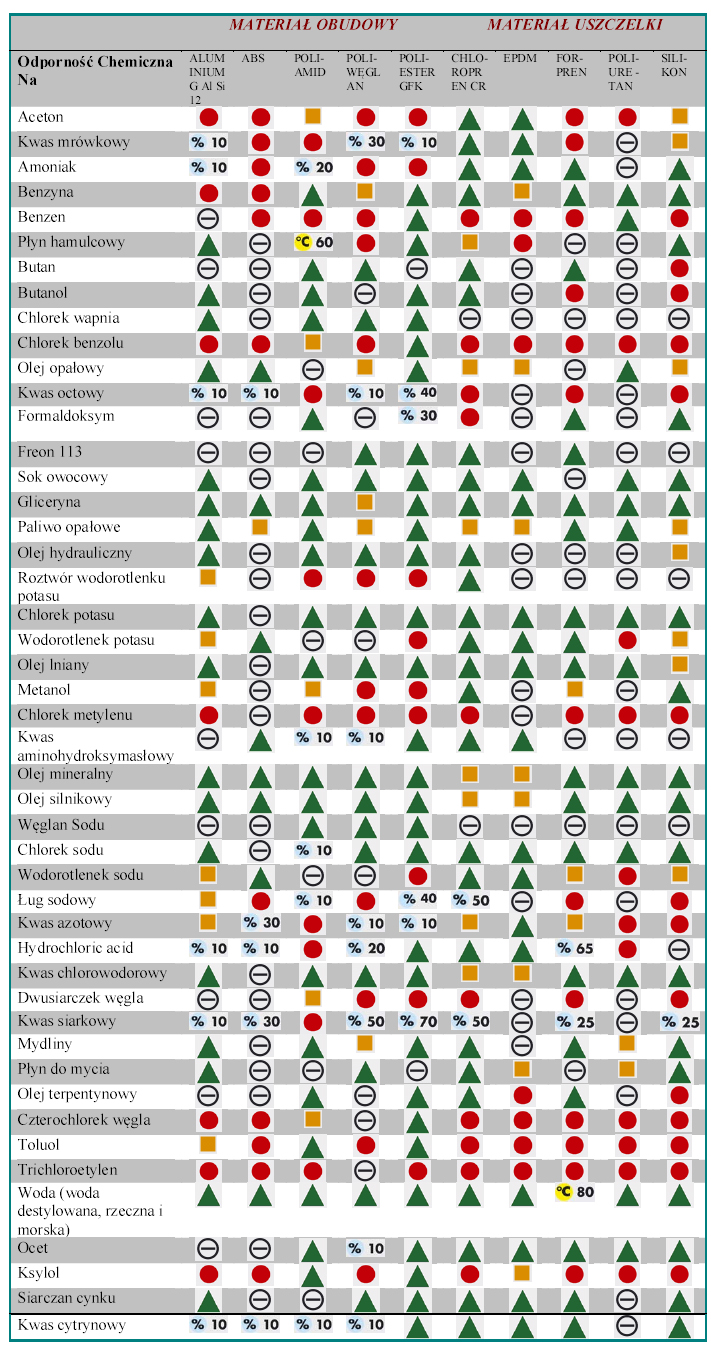

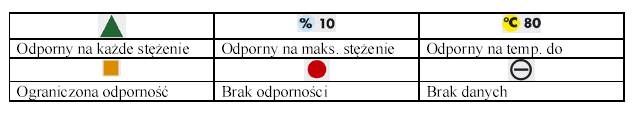

Therefore, we have created a table in cooperation with ROLEC that can be helpful in selecting the housing material for the operating conditions in which the device will operate. In addition to checking the housing material, you should also check the type of gasket used in the housing. The table includes general information and the chemicals that customers most frequently ask about. >

When selecting an enclosure, you should also keep in mind the general characteristics of the materials.

Polycarbonate (PC) – a material with good mechanical strength, a wide operating temperature range of -50°C - + 120°C, and good UV resistance.

Acrylonitrile-Butadiene-Styrene (ABS) – an easily machined material with good insulating properties. Unfortunately, it has poor UV resistance, inferior mechanical resistance to PC, and a narrower operating temperature range: -40°C - +80°C.

Glass fiber reinforced polyester (GFK) – a material with excellent mechanical and chemical resistance, fire resistance, high stiffness, and a wide operating temperature range. Mechanical processing is not as easy as with the above-mentioned materials.

Aluminum (AL) – a material with good chemical resistance, thanks to its powder coating, very good mechanical properties, a wide operating temperature range, and the possibility of EMC shielding, as well as very good housing stiffness. Mechanical processing is difficult and the material is heavy.

Marek Piątkowski – Zajec

DACPOL Sp. z o.o.

Are you interested in this product? Do you need additional information or individual pricing?

For an electronic device to function properly, it is necessary to analyze and predict the environment in which it will operate. Factors such as temperature, humidity, salinity, and chemical agents are just some of the parameters that should be considered when selecting appropriate components.

Therefore, we have created a table in cooperation with ROLEC that can be helpful in selecting the housing material for the operating conditions in which the device will operate. In addition to checking the housing material, you should also check the type of gasket used in the housing. The table includes general information and the chemicals that customers most frequently ask about. >

When selecting an enclosure, you should also keep in mind the general characteristics of the materials.

Polycarbonate (PC) – a material with good mechanical strength, a wide operating temperature range of -50°C - + 120°C, and good UV resistance.

Acrylonitrile-Butadiene-Styrene (ABS) – an easily machined material with good insulating properties. Unfortunately, it has poor UV resistance, inferior mechanical resistance to PC, and a narrower operating temperature range: -40°C - +80°C.

Glass fiber reinforced polyester (GFK) – a material with excellent mechanical and chemical resistance, fire resistance, high stiffness, and a wide operating temperature range. Mechanical processing is not as easy as with the above-mentioned materials.

Aluminum (AL) – a material with good chemical resistance, thanks to its powder coating, very good mechanical properties, a wide operating temperature range, and the possibility of EMC shielding, as well as very good housing stiffness. Mechanical processing is difficult and the material is heavy.

Marek Piątkowski – Zajec

DACPOL Sp. z o.o.

Your review appreciation cannot be sent

Report comment

Report sent

Your report cannot be sent

Write your review

Review sent

Your review cannot be sent